Home » Mailing Tubes and Order Minimums in Packaging

Mailing Tubes and Order Minimums in Packaging

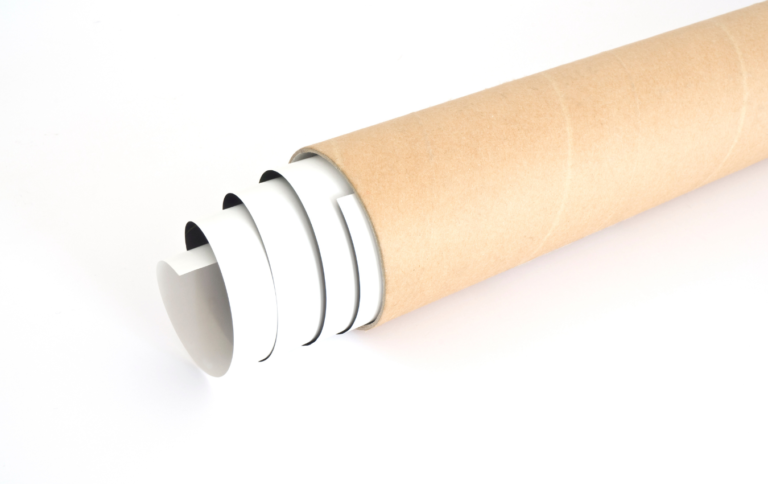

Mailing tubes are a popular choice for safely shipping and storing various items, such as posters, blueprints, and documents. While these tubes offer excellent protection and convenience, understanding order minimums in packaging is equally important, especially for businesses looking to source mailing tubes efficiently. In this comprehensive guide, we will explore mailing tubes, their advantages, and how order minimums can impact your packaging decisions.

The Advantages of Mailing Tubes

Before delving into order minimums, let’s examine why mailing tubes are favored for packaging:

- Protection: Mailing tubes provide a secure and protective enclosure for rolled or cylindrical items, preventing damage during transit.

- Versatility: They come in various lengths and diameters, making them suitable for a wide range of products, from artwork to blueprints.

- Convenience: Mailing tubes are easy to use, requiring minimal assembly and offering a hassle-free packing experience.

- Brand Presentation: They allow for branding and labeling, helping businesses convey their identity and professionalism.

Now, let’s explore the concept of order minimums:

Understanding Order Minimums

In the world of packaging, order minimums refer to the minimum quantity of a specific packaging product that a supplier requires you to purchase in a single order. These minimums can vary significantly among suppliers and depend on factors such as the type of packaging, size, and customization options.

Factors Impacting Order Minimums for Mailing Tubes

Several factors can influence the order minimums for mailing tubes:

- Size and Dimensions: Larger or custom-sized tubes may have higher minimum order quantities due to their specialized production requirements.

- Material and Customization: Tubes made from unique materials or with custom printing, branding, or finishes may have specific minimums.

- Supplier Policies: Each packaging supplier may have its own policies regarding minimum orders. Some suppliers cater to small businesses with lower minimums, while others primarily serve larger enterprises.

- Volume Discounts: Suppliers often offer volume discounts, encouraging customers to order larger quantities by reducing the cost per unit.

Determining the Right Order Quantity

When deciding on the order quantity for mailing tubes, consider the following factors:

- Usage Frequency: Assess how frequently you use mailing tubes in your packaging operations. Ordering in larger quantities may be cost-effective if you use them regularly.

- Storage Space: Consider your available storage space for bulk orders. Ensure you have adequate space to store the tubes without overcrowding your facility.

- Budget Constraints: Evaluate your budget and cash flow. Ordering larger quantities may require a more substantial upfront investment, so ensure it aligns with your financial capabilities.

- Supplier Relationships: Establish a relationship with a packaging supplier who understands your needs and offers flexible order minimums that match your requirements.

- Lead Times: Take into account the lead times required for manufacturing and delivery. Ordering larger quantities may allow you to reduce order frequency.

Custom Mailing Tubes and Order Minimums

If you require custom mailing tubes with unique dimensions, branding, or printing, be prepared for potentially higher order minimums. Customization often involves specialized production processes and setup costs that can impact minimum quantity requirements.

Conclusion

Mailing tubes are a valuable packaging solution for various industries and products. Understanding order minimums and their impact on your packaging decisions is crucial for efficient sourcing and cost-effective operations. By carefully assessing your usage needs, budget, and supplier options, you can strike the right balance between order quantities and packaging requirements. Establishing a reliable supplier relationship that aligns with your business goals is key to optimizing your mailing tube procurement strategy.

If you are interested in a large volume of mailing tubes, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Mailing Tubes and Order Minimums in Packaging