Home » Logistics and Installation: Streamlining POP Display Deployment

Logistics and Installation: Streamlining POP Display Deployment

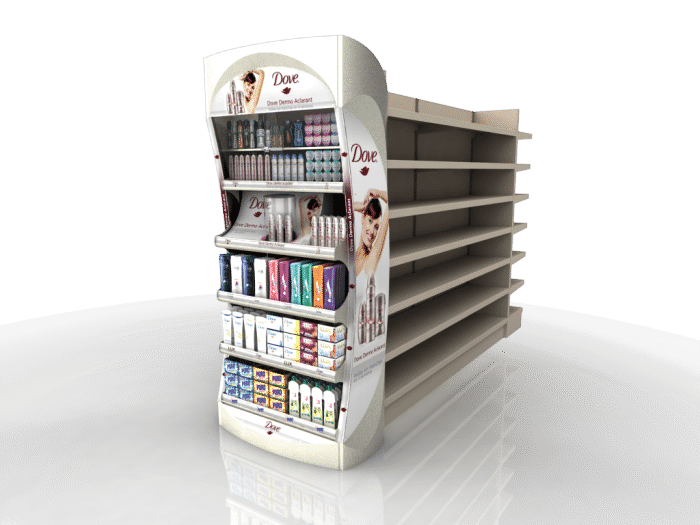

The final steps in deploying a permanent and semi-permanent Point of Purchase (POP) display involve the logistics of distribution and the specifics of installation. Effective management of these stages is crucial to ensure that your displays are set up correctly, on time, and with optimal impact. This blog will guide you through the logistics and installation processes, providing insights on how to streamline these operations for maximum efficiency and effectiveness.

Planning and Coordinating Logistics

Understanding Distribution Requirements

Begin by assessing the distribution requirements for your POP displays. Consider the number of locations, geographical spread, and the timeline for deployment. Effective logistics planning ensures that all displays reach their intended locations without delays or damage.

Choosing a Distribution Partner

Selecting the right logistics partner is vital. Look for providers with experience in handling retail displays, as they can offer specialized services such as on-time delivery to multiple locations, careful handling of materials, and even storage solutions if needed.

Packaging for Protection

Ensure that the POP displays are packaged securely to prevent damage during transit. This might involve custom crating or protective padding, especially for more delicate components. The goal is to have the displays arrive in pristine condition, ready for installation.

Efficient and Effective Installation

Preparing Installation Guidelines

Provide clear, detailed installation guidelines to ensure consistent setup across all locations. This should include instructions on assembly, placement, and any necessary tools or materials. Proper guidelines help minimize errors and reduce the time needed for installation.

Training Teams or Hiring Professionals

Decide whether to train your staff for installation or to hire professional installers. Training in-house teams can be cost-effective and allow for more control over the process. However, professional installers can offer the advantage of experienced, quick, and reliable setup, which might be crucial for complex displays or large-scale rollouts.

Coordinating with Retail Locations

Work closely with the management of the retail locations where the displays will be installed. Coordination is essential for ensuring that the installation process does not disrupt business operations and that the display is placed in the most effective spot within the store.

On-site Adjustments

Be prepared for on-site adjustments. Even with thorough planning, the need for minor tweaks during installation is common. Quick decision-making and adaptability can help overcome any unforeseen challenges that arise during the setup.

Monitoring and Troubleshooting

Initial Feedback Loop

Once the displays are installed, establish an initial feedback loop with the store managers and installation teams. Gather insights on the installation process and the initial response of customers to the displays. This feedback can be invaluable for making any immediate adjustments and for improving future deployments.

Ongoing Maintenance

Plan for the maintenance of the displays to ensure they remain attractive and functional throughout their intended lifespan. This might involve regular check-ups, cleaning, and repairs. Maintaining the displays well can significantly enhance their effectiveness and protect your investment.

Conclusion

Logistics and installation are critical phases in the deployment of POP displays. Efficiently managing these aspects ensures that your displays are set up to attract and engage customers effectively. By focusing on careful planning, clear communication, and flexibility, you can streamline these processes to achieve a successful display rollout that meets both your operational goals and marketing objectives.

If you are interested in POP displays, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Logistics and Installation: Streamlining POP Display Deployment

Creating impactful promotional messaging for Point of Purchase (POP) displays is vital for capturing customer interest and driving sales. This guide explores essential strategies for

When it comes to maximizing shelf space and capturing buyer attention, few pairings are more effective than folding cartons and POP displays. Whether it’s a

In the bustling world of retail, where competition is fierce and every inch of shelf space matters, staying ahead requires innovation. You’ve cultivated an exceptional