Home » Load Bearing Design Principles for Corrugated POP Displays

Load Bearing Design Principles for Corrugated POP Displays

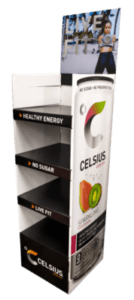

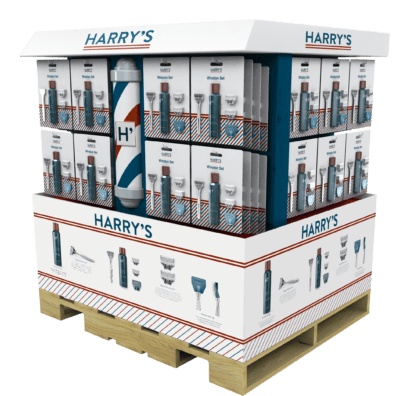

POP displays must balance eye-catching branding with structural integrity. Inadequate load-bearing design can result in product sagging, leaning, or complete collapse, which not only risks product loss but also damages retailer confidence. By applying engineering principles, testing protocols, and correct material selection, brands can maximize display stability without unnecessary cost.

Understanding Load-Bearing Capacity

- Static Load vs. Dynamic Load:

- Static load refers to the total weight a display can hold without movement.

- Dynamic load accounts for forces during handling, stocking, and customer interaction.

- Failure Modes: Panel buckling, shelf deflection, joint separation, and base collapse are the most common failure points.

Material Selection

- Corrugated Board Strength:

- Flute profile (B, C, E, or BC) impacts stiffness and stacking strength.

- Higher ECT boards increase vertical load capacity but also affect cost and weight.

- Coatings and Laminates:

- Water-resistant coatings prevent fiber weakening in humid environments.

- Laminates can increase rigidity but may impact recyclability.

Structural Reinforcements

- Double-Wall Shelving: For heavier products such as beverages or canned goods.

- Internal Braces: Die-cut supports hidden behind the graphic panels for increased stability.

- Base Skids: Distributes load more evenly to prevent floor contact wear and pallet jack damage.

Design and Geometry

- Weight Distribution: Heavier SKUs should be placed at lower tiers to reduce tipping risk.

- Joint Engineering: Lock tabs, glue flaps, and interlocking slots improve structural stability.

- Shear Resistance: Cross-bracing and panel alignment reduce the risk of diagonal collapse.

Testing Protocols

- ASTM D642: Measures compression strength to determine safe stacking loads.

- ISTA 3A & 6-Series: Simulates real-world handling, vibration, and impact.

- Shelf Deflection Tests: Measures how much a shelf bends under load over time.

Best Practices

- Always design for at least 25% higher load capacity than the expected maximum product weight.

- Validate prototypes under realistic load and environmental conditions before production.

- Balance cost-to-performance ratio — over-engineering increases cost without visible retail benefit.

References

ASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://www.astm.org/d0642-15.html

International Safe Transit Association. (2018). ISTA 3A general simulation performance test for packaged-products for parcel delivery system shipment. ISTA. https://ista.org/

International Safe Transit Association. (2018). ISTA 6-Series transit tests. ISTA. https://ista.org/

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Load Bearing Design Principles for Corrugated POP Displays