Home » Key Insights on Anti-Static Packaging

Key Insights on Anti-Static Packaging

In an era where electronic components and sensitive products are more prevalent than ever, understanding and utilizing anti-static packaging has become essential for businesses. This blog post delves into the significance, types, and considerations of anti-static packaging, highlighting its critical role in protecting sensitive items from static damage.

The Importance of Anti-Static Packaging

Static electricity can be a silent but deadly foe for electronic components and other sensitive products. Even a small amount of static discharge can damage or destroy these items. This is where anti-static packaging plays a pivotal role, by preventing the build-up of static electricity and protecting the products during storage and transportation.

Types of Anti-Static Packaging

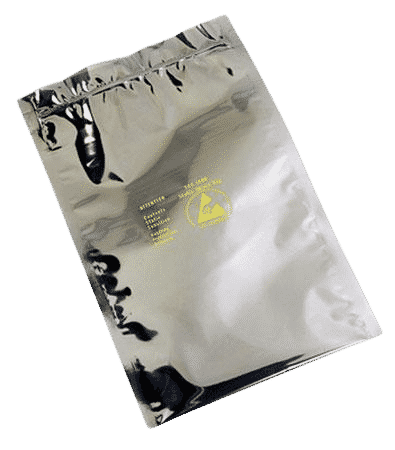

- Anti-Static Bags: These are the most common type of anti-static packaging. Made from plastic with an anti-static coating, they prevent the build-up of static inside the bag. Ideal for small electronic parts like RAM, hard drives, and motherboards.

- Conductive Bins and Totes: Used for larger components or for transportation of multiple items, these containers offer a conductive surface that dissipates static charge.

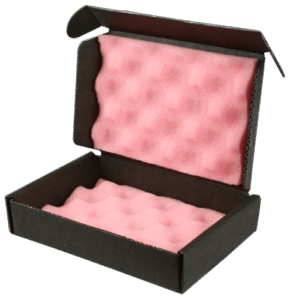

- Foams and Bubble Wraps: Anti-static foam and bubble wrap provide cushioning while also preventing static build-up, making them perfect for delicate or shock-sensitive items.

- Static Shielding Bags: These offer more protection than regular anti-static bags by also protecting the contents from static charges outside the bag.

Why Choose Anti-Static Packaging?

- Protects Sensitive Equipment: The primary purpose is to safeguard electronic components and other static-sensitive products from static damage.

- Reduces Returns and Complaints: By ensuring products arrive in working condition, anti-static packaging reduces the likelihood of returns and customer complaints.

- Compliance with Industry Standards: Many industries mandate the use of anti-static packaging for certain products, making it not just a choice but a compliance issue.

Considerations When Selecting Anti-Static Packaging

- Type of Product: The nature of the product (size, sensitivity to static, value) will determine the type of anti-static packaging needed.

- Cost-Effectiveness: While essential for certain products, anti-static packaging can be more expensive than standard options. Balancing cost with necessity is key.

- Environmental Impact: Some businesses may seek eco-friendly options, as traditional anti-static materials can be less biodegradable.

- Storage and Handling Requirements: Certain anti-static packaging materials may have specific storage or handling requirements to maintain their effectiveness.

Conclusion

Anti-static packaging is a critical component in the safe handling and shipping of electronic and static-sensitive products. Understanding the different types and their appropriate applications can help businesses protect their products, reduce losses, and maintain customer satisfaction. As technology continues to evolve, the importance of anti-static packaging is only set to increase, making it an indispensable part of modern product handling and logistics.

If you are interested in anti-static packaging, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Key Insights on Anti-Static Packaging

Internal components, such as delicate electronics, mechanical parts, or fragile materials, require specialized protective packaging to ensure they arrive intact and functional. Whether you’re shipping

When it comes to packaging fragile or valuable items, ensuring their safe transportation is crucial. One effective way to protect these items during shipping or

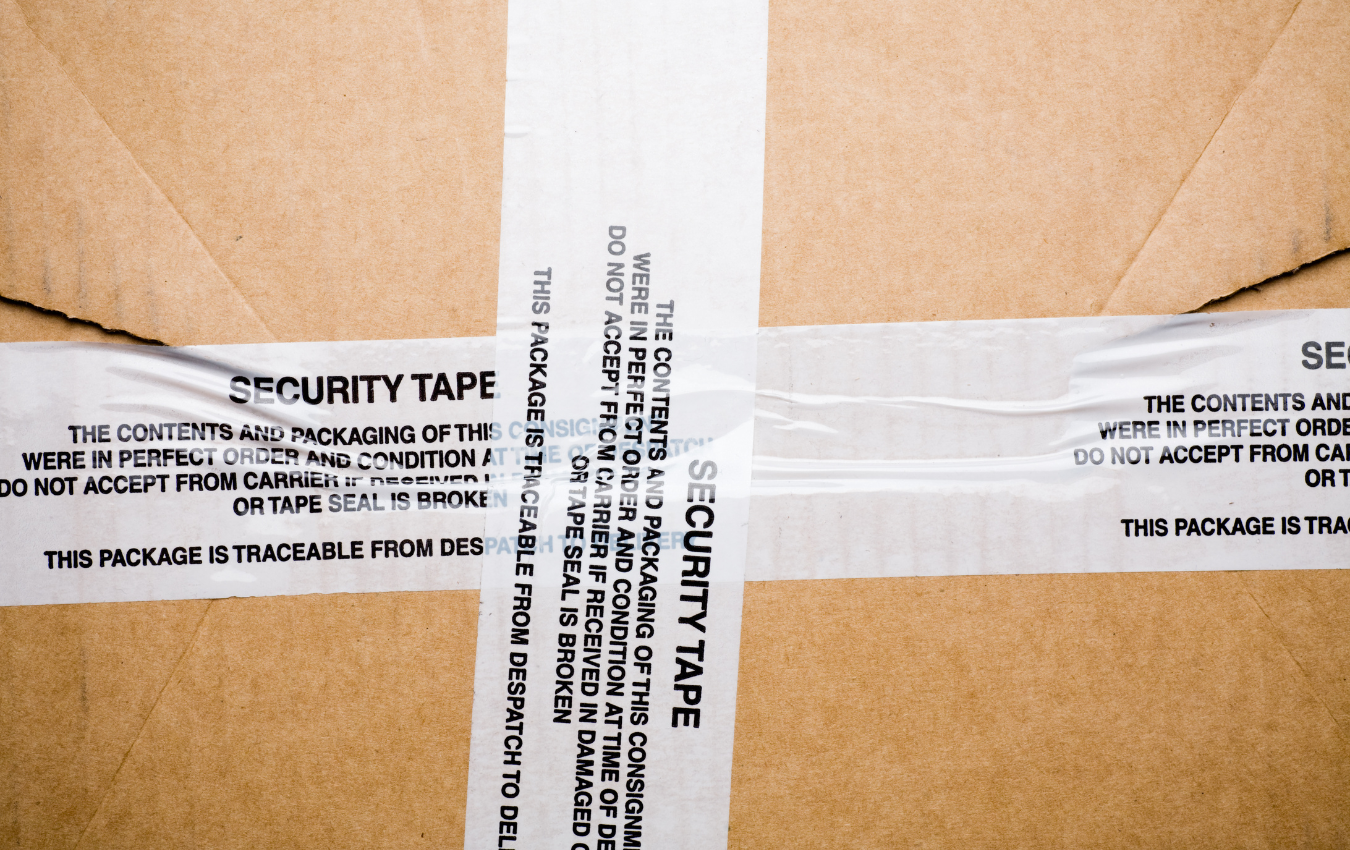

Tampering and theft are significant concerns for manufacturers and consumers alike. Tampered products can pose health and safety risks, while theft results in financial losses.