Home » How Edge Protectors are Enhancing Sustainability in the Packaging Industry

How Edge Protectors are Enhancing Sustainability in the Packaging Industry

In recent years, sustainability has become a key focus in various industries, including packaging. As companies strive to minimize their environmental footprint, innovative solutions are being developed to promote sustainable practices. One such solution is the use of edge protectors in the packaging industry. Edge protectors not only provide structural support and protection for packaged goods, but they also contribute significantly to enhancing sustainability.

This blog explores the various ways in which edge protectors are enhancing sustainability in the packaging industry.

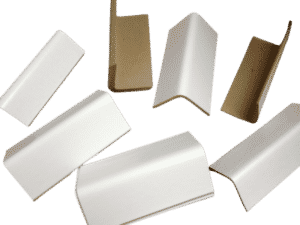

Understanding Edge Protectors

Before delving into their sustainable benefits, let’s understand what edge protectors are. Edge protectors, also known as corner protectors, are typically made from materials like cardboard, paperboard, or plastic. They are designed to reinforce and protect the edges and corners of packaging, preventing damage during transit and handling. Edge protectors are available in various sizes and configurations to suit different packaging needs.

Reducing Material Waste

One of the significant advantages of using edge protectors is their ability to reduce material waste in the packaging industry. By reinforcing the edges and corners of packages, they minimize the risk of damage during transportation. This reduces the need for excessive cushioning materials, such as foam or bubble wrap, which are often used to protect vulnerable areas. Edge protectors act as a first line of defense, enabling packaging to withstand external pressures and reducing the overall material waste.

Enhancing Product Protection

Another way edge protectors contribute to sustainability is by enhancing product protection. When packaged goods are damaged during transit, they often end up as waste, resulting in financial losses for businesses and environmental impact. By providing additional structural support, edge protectors minimize the likelihood of product damage. This not only reduces the waste generated but also extends the lifespan of the packaged goods, leading to a more sustainable approach.

Facilitating Reusability and Recyclability

Edge protectors are often made from recyclable materials such as cardboard or paperboard. This makes them highly suitable for reuse and recycling. Unlike some other packaging materials, edge protectors can be easily separated from the primary packaging and recycled separately. This promotes a circular economy, where materials are reused and recycled rather than disposed of after a single use. By incorporating recyclable edge protectors, companies can minimize their environmental impact and contribute to sustainable packaging practices.

Optimizing Packaging Efficiency

Efficiency plays a crucial role in sustainable packaging practices. Edge protectors can help optimize packaging efficiency by allowing for better stacking and utilization of space. By reinforcing the edges and corners, packages can be stacked more securely, reducing the risk of collapse and maximizing the use of available storage and transportation space. This, in turn, leads to fewer trips required for transportation, reduced fuel consumption, and lower carbon emissions. By improving packaging efficiency, edge protectors contribute to overall sustainability efforts.

Supporting Lightweight Packaging

With the rising focus on reducing carbon emissions and transportation costs, lightweight packaging has gained prominence. Edge protectors enable the use of lighter packaging materials by providing structural integrity to the package. By reinforcing the edges and corners, edge protectors allow companies to use thinner materials without compromising the protection of the packaged goods. This helps reduce the overall weight of the packaging, leading to lower transportation costs and reduced energy consumption during transportation.

Summary: Edge Protectors and Sustainability

Edge protectors play a vital role in enhancing sustainability within the packaging industry. They not only reduce material waste but also enhance product protection, facilitate reusability and recyclability, optimize packaging efficiency, and support lightweight packaging. As companies increasingly adopt sustainable practices, incorporating edge protectors into their packaging solutions becomes an essential step towards reducing environmental impact. By embracing edge protectors, businesses can contribute to a greener future and promote a more sustainable packaging industry overall.

If you are interested in edge protectors and/or sustainable solutions, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » How Edge Protectors are Enhancing Sustainability in the Packaging Industry

E-commerce packaging for pet products must endure far more stress than traditional retail packaging. Shipments face repeated drops, vibration, compression, and environmental fluctuations. Structural design,

Full-Overlap (FOL) boxes are renowned for their structural integrity and robust design, making them a popular choice for packaging products that require extra protection during

Temperature fluctuations can have a detrimental effect on your products and packaging. Whether your goods are sensitive to extreme heat or cold, maintaining the right