Home » Corporate Packaging Strategy for 2025

Corporate Packaging Strategy for 2025

For large businesses and corporations, packaging is more than just a protective shell—it’s an integral part of brand identity, supply chain efficiency, and consumer experience. With increasing competition, regulatory challenges, and rising costs, corporations must take a strategic approach to packaging in 2025. The right packaging strategy can enhance brand perception, reduce costs, and improve overall product performance in the market.

Key Focus Areas for Corporate Packaging

Scalable and Cost-Effective Production

Large businesses require packaging solutions that can handle high-volume production while maintaining cost efficiency. This means:

- Standardizing packaging materials and sizes to streamline production.

- Optimizing material usage to reduce costs while maintaining structural integrity.

- Working with reliable suppliers to ensure stable pricing and on-time delivery.

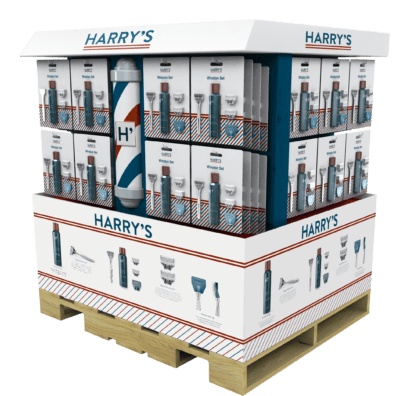

Supply Chain Optimization and Logistics Efficiency

Efficient packaging design can lead to major savings in storage and transportation. Corporations should focus on:

- Right-sizing packaging to minimize shipping costs and dimensional weight charges.

- Stackable and space-efficient designs to reduce warehouse storage costs.

- Durability and protection to lower product damage rates and returns.

Compliance and Industry Standards

Regulatory compliance is a major concern for large corporations, especially in industries such as food, pharmaceuticals, and electronics. Businesses must ensure:

- Packaging meets FDA, ISO, FSC, and industry-specific certifications.

- Labels and warnings comply with legal and safety requirements.

- Tamper-evident and traceable packaging solutions for product security.

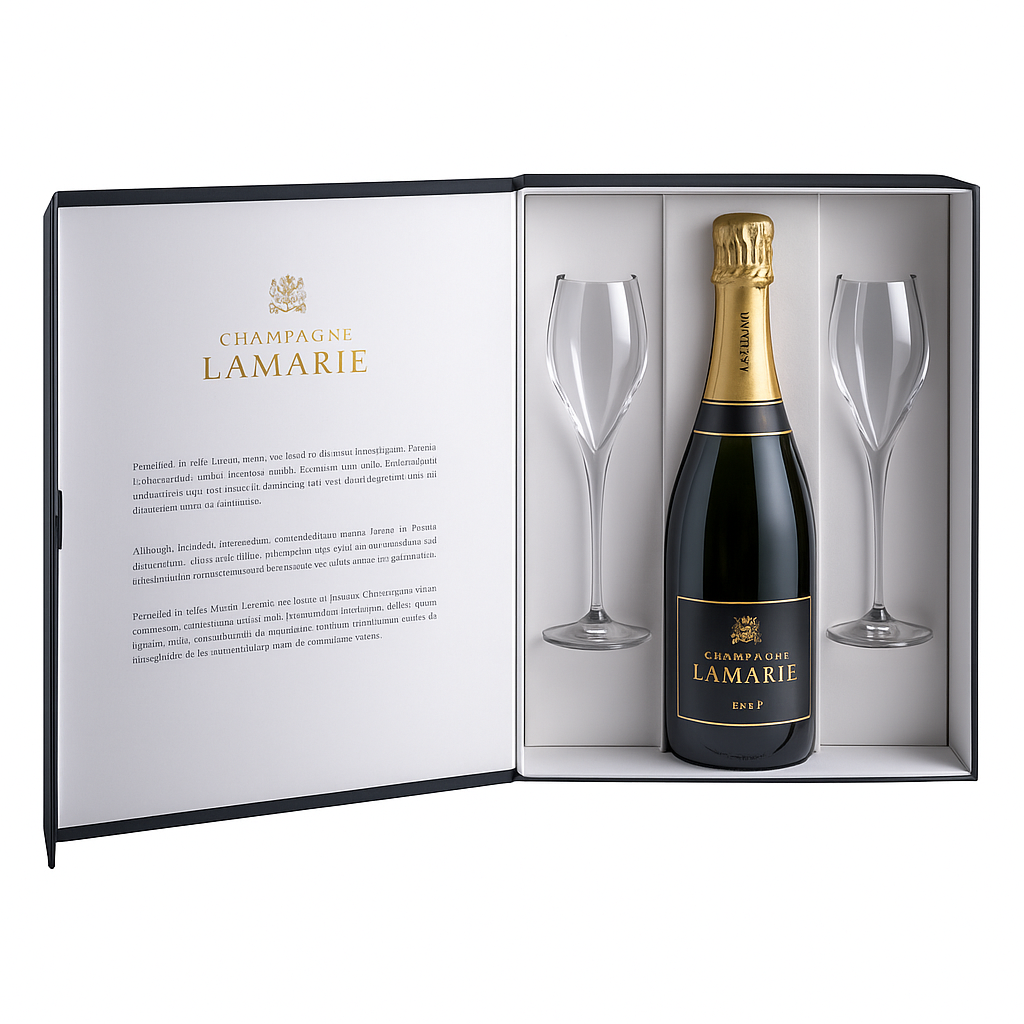

Brand Consistency and Market Appeal

For corporations with multiple product lines and global reach, consistent branding across all packaging is essential. This includes:

- Unified design elements across different regions and product categories.

- Premium printing and finishing options for high-end product lines.

- Localized packaging variations to meet international market preferences.

Sustainable and Responsible Packaging

While cost and efficiency are priorities, many corporations are also focusing on eco-friendly packaging solutions. Strategies include:

- Lightweight materials to reduce carbon footprint and shipping costs.

- Recyclable or biodegradable packaging to align with consumer demand.

- Supply chain transparency to meet sustainability reporting requirements.

Automation and Packaging Technology Integration

Corporate packaging strategies should leverage automation and smart packaging technology for efficiency and innovation. This includes:

- Automated packaging lines to reduce labor costs and increase production speed.

- RFID tags and QR codes for enhanced tracking and consumer engagement.

- Smart packaging materials that provide real-time data on freshness and handling.

Final Thoughts: The Corporate Packaging Strategy for 2025

For large businesses, packaging is a strategic asset that affects branding, supply chain efficiency, and compliance. By focusing on cost-effective production, logistics efficiency, regulatory standards, and sustainability, corporations can stay ahead in 2025 and beyond.

Looking for scalable and innovative packaging solutions for your business? Contact Brown Packaging today to optimize your corporate packaging strategy.

It’s Not About Spending Less—It’s About Spending Right

Your goal isn’t to cut corners—it’s to make sure your packaging spend matches your sales goals, brand perception, and market environment. In many cases, a simple structural or material tweak can reduce costs without affecting how the package performs or looks.

Small changes might include:

- Switching from rigid box to folding carton

- Simplifying closures or removing magnetic flaps

- Moving from offset to digital print for short runs

- Using standard dielines instead of custom shapes

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

Home » Corporate Packaging Strategy for 2025