Home » Choosing Materials and Production for Your POP Display

Choosing Materials and Production for Your POP Display

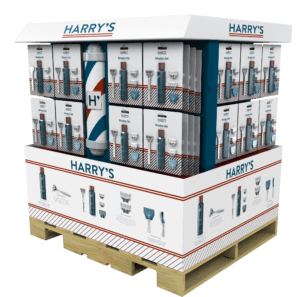

The selection of materials and the production process are critical aspects of creating a Point of Purchase (POP) display that not only captures attention but is also cost-effective and durable. This stage in the creation of a POP display involves deciding on the materials that will best convey the brand message while standing up to the retail environment. This blog explores how to choose the right materials for your POP display and discusses key considerations for the production process.

Material Selection: Balancing Aesthetics, Budget, and Durability

Understand Material Options

The most common materials used in POP displays include cardboard, plastic, metal, and wood. Each has its advantages and drawbacks:

- Cardboard (Corrugated) is cost-effective and versatile but less durable.

- Plastic offers durability and a clean look but can be more expensive.

- Metal is highly durable and stable, suitable for heavier products.

- Wood provides a premium aesthetic but is often heavier and more costly.

Consider Environmental Factors

Select materials that are appropriate for the display’s environment. For indoor displays, durability concerns might be less stringent than for outdoor displays. Additionally, consider the sustainability of materials if environmental impact is a concern for your brand.

Align with Budget

Your material choice is heavily influenced by your budget. While it’s important to aim for high-quality, cost-effective materials that offer visual appeal and durability, ensure they do not stretch your budget too thin. Plan to allocate resources efficiently to balance between material costs and other elements like design and transportation.

Production Process: Ensuring Quality and Efficiency

Choose the Right Manufacturer

Selecting a manufacturer is a pivotal decision in the production process. Look for manufacturers with experience in producing similar types of displays, good reputations for quality and reliability, and the ability to provide valuable insights and adjustments to your design.

Prototype Testing

Before moving into mass production, ensure that a prototype of the display is tested. This helps in identifying any potential issues with the design or materials that might affect the display’s functionality or durability.

Quality Control

Establish a strict quality control process with your manufacturer to ensure that every display meets your standards. Consistent quality is crucial, as any defects can detract from the effectiveness of your display and potentially harm your brand’s reputation.

Consider Assembly and Installation

Think about the assembly process for your display. If the displays need to be assembled on-site, ensure that they are designed to be easily put together, with clear instructions provided. This can significantly affect the overall success of the display deployment.

Plan for Logistics

Coordinate with the manufacturer about logistics. This includes the packaging of the displays for shipment and the delivery schedules to ensure that displays arrive in good condition and on time for deployment.

Conclusion

Choosing the right materials and overseeing a careful production process are essential steps in creating effective POP displays. By considering factors like material properties, budget constraints, and environmental conditions, and by working closely with a reliable manufacturer, you can ensure that your POP display effectively represents your brand and engages your target audience. This attention to detail in the production phase will pay dividends in the display’s success and durability.

If you are interested in POP displays, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Choosing Materials and Production for Your POP Display

Seasonal promotions are among the most powerful opportunities for brands to capture attention in retail environments. From holidays to back-to-school campaigns, point-of-purchase (POP) displays serve

Creating an effective Point of Purchase (POP) display can be a game changer for any retail business, influencing buying decisions and enhancing product visibility. For

Point of Purchase (POP) displays are an effective way to promote products and increase sales in retail environments. The trends for POP displays in 2023