Home » Benefits of Edge Protectors for Pallet Shipping

Benefits of Edge Protectors for Pallet Shipping

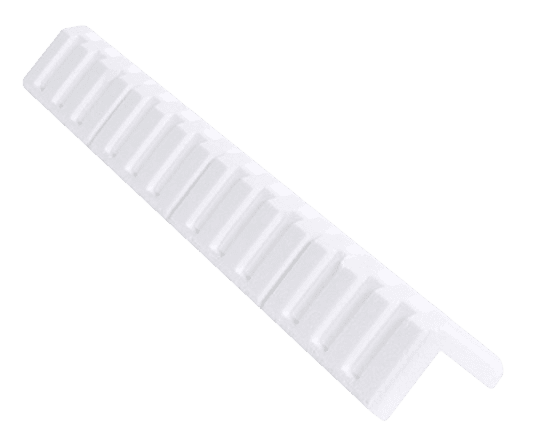

In shipping large quantities of goods, ensuring the safety and stability of pallet loads is paramount. Edge protectors play a vital role in protecting palletized shipments from damage during transportation and handling. This blog explores how edge protectors enhance the security of pallet loads, their types, and the benefits they bring to logistics and supply chains.

What Are Edge Protectors?

Edge protectors, also known as corner protectors, are sturdy materials placed along the edges of palletized loads to provide reinforcement and protection. Typically made from plastic, corrugated, or foam materials, edge protectors prevent damage to packaging and products during strapping, stacking, and transit. They come in various sizes, thicknesses, and shapes, such as L-shaped or flat, to suit different load configurations.

Types of Edge Protectors

Plastic Edge Protectors

- Material: High-density polyethylene (HDPE).

- Uses: Ideal for securing heavy pallet loads.

- Benefits: Strong and durable, resistant to moisture and impact, and reusable.

Corrugated Edge Protectors

- Material: Sturdy corrugated board.

- Uses: Suitable for eco-conscious businesses or lighter palletized goods.

- Benefits: Lightweight, recyclable, and customizable in length and thickness.

Foam Edge Protectors

- Material: Shock-absorbing foam.

- Uses: Best for fragile or sensitive products on pallets.

- Benefits: Provides superior cushioning against impacts and vibrations during transport.

Benefits of Edge Protectors for Pallet Loads

- Enhanced Stability

Edge protectors help secure straps tightly around palletized loads, reducing the risk of movement or shifting during transportation. This stability minimizes the likelihood of toppled pallets and damaged products.

- Prevents Strap Damage

Tensioned straps can dig into packaging, causing tears or deformation. Edge protectors distribute the pressure evenly across the load, safeguarding both the packaging and the products inside.

- Improved Load Integrity

By reinforcing the corners and edges of a pallet load, edge protectors prevent crushing and damage, particularly for cartons stacked at the bottom of the pallet.

- Reduced Shipping Costs

Minimizing damage to goods lowers the risk of returns and replacements, reducing overall shipping expenses and improving profit margins.

- Streamlined Stacking and Storage

Edge protectors maintain the structural integrity of stacked pallets, allowing for safe and efficient storage in warehouses or during transit.

- Enhanced Sustainability

Corrugated edge protectors are biodegradable and recyclable, making them an eco-friendly choice for businesses aiming to reduce their environmental impact.

- Protection Against Legal Liability

Properly secured pallet loads with edge protectors demonstrate due diligence in product safety, reducing the risk of legal disputes over damaged goods during transportation.

Customization for Pallet Loads

Edge protectors can be customized to fit the unique requirements of palletized shipments:

- Length and Thickness: Tailor edge protectors to match pallet dimensions and load weight.

- Materials: Choose foam for fragile products or plastic for heavier loads.

- Branding: Add logos or company branding for enhanced visibility and professional presentation.

Conclusion

Edge protectors are indispensable for protecting palletized goods during shipping, ensuring stability, reducing damage, and lowering costs. They provide a cost-effective solution to safeguard products, maintain load integrity, and enhance overall operational efficiency.

Interested in stock or custom edge protectors for palletized loads? Contact Brown Packaging today to explore options tailored to your business needs.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » Benefits of Edge Protectors for Pallet Shipping