Home » Balancing Visual Impact and Logistics in POP Displays

Balancing Visual Impact and Logistics in POP Displays

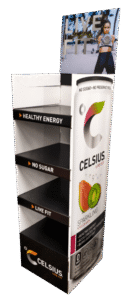

Point-of-purchase (POP) displays must catch a shopper’s eye while also moving efficiently through the supply chain. Striking the right balance between visual impact and logistics ensures displays drive sales without creating costly inefficiencies. A design that leans too far toward graphics may ship poorly, while one built only for logistics risks blending into the background.

The Role of Visual Impact

Graphics and structure are central to a display’s retail performance. Visual impact drives traffic and communicates the brand message at a glance.

- Bold colors and large product imagery attract attention.

- Clean layouts improve readability in busy aisles.

- Seasonal themes and promotions build urgency.

Without strong branding, even the most efficient display may fail to engage shoppers.

Logistics Demands in POP Displays

Retailers expect displays that not only sell but also ship and set up efficiently. Logistics considerations include:

- Cube efficiency: Displays should maximize pallet and trailer space.

- Durability: Strength to withstand transit and handling.

- Ease of assembly: Retail staff need quick setup without extra labor.

- Compliance: Dimensions must meet retailer guidelines for footprint and safety.

Strategies to Balance Both Sides

- Collaborative design: Structural and graphics teams work together from the start.

- Prototype testing: Confirm visual alignment and shipping durability before production.

- Material selection: Choose corrugated grades that allow high-quality print and strength.

- Right-size graphics: Design branding that adapts to fold lines and pallet constraints.

Examples of Balanced POP Designs

- Club store pallet displays: Large branding surfaces combined with pallet-ready engineering.

- Seasonal promotions: Bold graphics with lightweight, compact shipping formats.

- Cross-merchandising units: Multi-SKU designs that showcase brands while stacking efficiently.

POP Display Solutions with Brown Packaging

Brown Packaging creates POP displays that deliver both retail impact and supply chain efficiency. Our designs maximize brand presence while meeting freight, compliance, and setup demands. Contact us to explore display options that balance impact with logistics.

References

Shop! Association. (2021). Best Practices for In-Store Marketing and POP Displays. Retrieved from https://www.shopassociation.org

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

ASTM International. (2022). ASTM D685: Standard Practice for Conditioning Paper and Paper Products for Testing.

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping,

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Home » Balancing Visual Impact and Logistics in POP Displays

In retail, the ease with which customers can interact with products directly influences their purchasing decisions. Point of Purchase (POP) displays designed with accessibility in mind are pivotal for enhancing customer experience and boosting sales. This blog dives into the concept of product accessibility within POP displays, highlighting strategies to maximize ease of access and encourage active engagement. The Importance of Product Accessibility Product accessibility in a retail setting means more than just physical reach; it involves making products approachable, understandable, and engaging through well-thought-out display designs. Effective POP displays remove barriers that could deter a customer from interacting with the product, thereby increasing the likelihood of a purchase. Key Strategies for Accessible POP Displays Minimize Physical Barriers Ensure that products within POP displays are easy to reach and interact with. Avoid high shelves or deep bins where products might be out of reach for some customers. Consider the layout and height of your displays to accommodate all customers, including those who might be wheelchair users or of short stature. Interactive Elements Incorporate elements that invite interaction, such as touchscreens with product information, samples for testing, or QR codes that link to detailed product demonstrations. Interactive displays not only improve accessibility but also enhance the shopping experience, making it more informative and engaging. Clear and Concise Signage Use clear, easily readable signage that guides and educates the customer. Signage should be visible from a distance and at eye level, using simple language to explain the product benefits and how to use them. This reduces confusion and empowers customers to make informed decisions quickly. Optimal Placement Position POP displays in locations where customers naturally pause, such as at eye level on end caps, near product categories that complement the display items, or along paths that most customers travel. Strategic placement ensures products are not only accessible but also unavoidable as customers navigate through the store. Use of Lighting Enhance product visibility and appeal through effective lighting. Well-lit displays draw attention to the products and can influence mood and perception. Consider using spotlights or LED lighting to highlight specific products or features, making them more inviting to customers. Regular Updates Keep your POP displays fresh and relevant by regularly updating them to reflect new products, seasonal items, or current promotions. This keeps returning customers engaged and ensures that the display maintains its appeal over time. Conclusion Understanding and improving product accessibility in POP displays is essential for creating effective retail environments. By implementing strategies that enhance physical access, interaction, and comprehension, retailers can significantly boost customer engagement and sales. Accessible POP displays not only cater to a wider audience but also foster a more inclusive shopping experience. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts

Point of Purchase (POP) displays are a dynamic marketing tool used to engage customers and boost sales at the point of decision-making. Whether you’re a retailer or a brand looking to promote your products effectively, creating a successful POP display requires careful planning and execution. In this comprehensive buyer’s guide, we’ll walk you through the essential 10 steps to begin your journey into the world of POP displays. Define Your Goals and Objectives Know Your Target Audience Determine Placement Design the Display Budget and Resources Manufacturing and Assembly Testing and Refinement Deployment and Installation Monitor and Evaluate Adapt and Optimize Step 1: Define Your Goals and Objectives Before diving into the design and creation of a POP display, it’s crucial to establish clear goals and objectives. Ask yourself: What specific products or promotions do you want to highlight? What are your sales targets and timeframes? Are you aiming to increase brand visibility, introduce a new product, or boost impulse purchases? Having a well-defined purpose for your POP display will guide your decision-making throughout the process. Step 2: Know Your Target Audience Understanding your target audience is fundamental to designing an effective POP display. Consider factors such as demographics, preferences, and buying behavior. Knowing your audience allows you to tailor your display to appeal directly to them. Step 3: Determine Placement Identify the optimal location for your POP display within the retail space. Factors to consider include foot traffic patterns, visibility, and proximity to related products. Collaborate with the retailer to secure a prime location if possible. Step 4: Design the Display This step involves creating the visual and structural elements of your POP display. Key considerations include: Eye-Catching Design: Use attractive visuals, colors, and graphics that align with your brand identity and resonate with your target audience. Product Placement: Arrange products strategically, ensuring they are accessible and easy to reach for customers. Signage and Messaging: Incorporate clear and concise signage that conveys product information, benefits, and pricing. Branding: Maintain consistency in branding elements, including logos, fonts, and color schemes. Materials and Durability: Select high-quality materials and construction that can withstand the rigors of a retail environment. Step 5: Budget and Resources Determine your budget for creating and implementing the POP display. Consider costs related to design, materials, manufacturing, and installation. Allocate resources accordingly to ensure a smooth execution. Step 6: Manufacturing and Assembly Choose a reputable manufacturer or supplier to bring your POP display to life. Ensure that the manufacturing process aligns with your design specifications and quality standards. Assembly and construction should be easy and straightforward for store personnel. Step 7: Testing and Refinement Before final deployment, conduct tests to ensure that the POP display functions as intended. Consider factors like customer interaction, stability, and overall appeal. Make any necessary refinements based on feedback and insights. Step 8: Deployment and Installation Coordinate with the retailer to install the POP display in the designated location. Ensure that installation is completed correctly and that all elements are in place. Step 9: Monitor and Evaluate Track the performance of your POP display by monitoring sales data, customer feedback, and other relevant metrics. Evaluate its effectiveness in achieving your goals and objectives. Step 10: Adapt and Optimize Based on your evaluation, make adjustments to your POP display strategy as needed. This could include changes in design, placement, messaging, or product selection. Continuously adapt and optimize your approach to maximize results. Conclusion Creating a successful POP display is a strategic process that begins with setting clear goals, understanding your audience, and carefully planning every aspect of design and execution. By following these essential steps outlined in this buyer’s guide, you can embark on your POP display journey with confidence, knowing that you are on the path to capturing customer attention, boosting sales, and enhancing your brand’s visibility in the retail environment. Keep in mind that ongoing evaluation and adaptation are key to ensuring the continued success of your POP displays. If you are interested in point of purchase displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

In the retail environment, the placement of Point of Purchase (POP) displays is just as critical as their design and content. Strategic positioning can significantly influence consumer behavior, increase product visibility, and drive sales. This blog explores the importance of strategic placement for POP displays and provides insights on how to maximize their effectiveness through optimal positioning. Understanding Consumer Traffic Flow The effectiveness of a POP display largely depends on its ability to catch the consumer’s eye. To achieve this, retailers must first understand the natural traffic flow within their store. This involves analyzing which areas receive the most foot traffic and where customers pause, browse, or make decisions. Placing POP displays in these high-traffic or high-engagement zones can increase the likelihood of interaction and purchase. Prime Locations for POP Displays Near the Entrance Placing POP displays near the entrance captures the attention of customers as soon as they enter the store. This position can be used to promote new arrivals, seasonal items, or special offers, setting the tone for the shopping experience. At the End of Aisles The end of an aisle, or endcap, is a premium spot for POP displays. As customers navigate the aisles, endcaps serve as focal points that draw their gaze. These locations are ideal for showcasing bestsellers, promotional items, or products that benefit from high visibility. Checkout Areas The checkout area is a hotspot for impulse buys. While customers wait in line, they are more likely to browse and pick up additional items. POP displays placed near or around the checkout can capitalize on this by featuring small, easy-to-decide-on products. Transition Zones Areas where customers transition from one part of the store to another, such as the entrance to a specialty section, are strategic for placement. These locations can be leveraged to introduce customers to products or deals that relate to their shopping journey. Integrating Placement with Store Layout Effective POP display placement should feel organic and integrate seamlessly with the overall store layout. Displays should not obstruct the flow of traffic or overwhelm customers but should enhance the shopping experience by being both informative and persuasive. The Role of Visibility and Accessibility Visibility is paramount in effective POP display placement. Displays should be positioned at eye level or in direct line of sight to ensure they are not overlooked. Additionally, products on the display should be easily accessible; customers should be able to interact with the products without any hindrance. Using Data-Driven Insights for Placement Decisions Leveraging sales data and customer behavior analytics can provide valuable insights into where POP displays would be most effective. A/B testing different placements can also help determine the most impactful locations based on actual customer interaction and sales conversion rates. Conclusion The strategic placement of POP displays is a critical component in maximizing their effectiveness. By understanding customer behavior, leveraging high-traffic locations, and ensuring visibility and accessibility, retailers can significantly enhance the impact of their POP displays. Thoughtful placement, combined with compelling design and relevant content, ensures that POP displays are not just seen but are also effective in driving purchases. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts