Home » Are Corrugated Boxes Effective?

Are Corrugated Boxes Effective?

Corrugated boxes are highly effective for a wide range of packaging needs, providing superior protection, durability, and versatility. Their unique construction allows them to withstand various stresses during shipping and storage, making them a preferred choice for businesses and consumers alike.

The Structure of Corrugated Boxes

The effectiveness of corrugated boxes starts with their structure. Made from corrugated fiberboard, which includes a fluted corrugated sheet sandwiched between two flat linerboards, these boxes offer a robust design capable of absorbing shock and preventing damage to the contents. This structure not only imparts strength but also provides insulation that can protect against temperature variations.

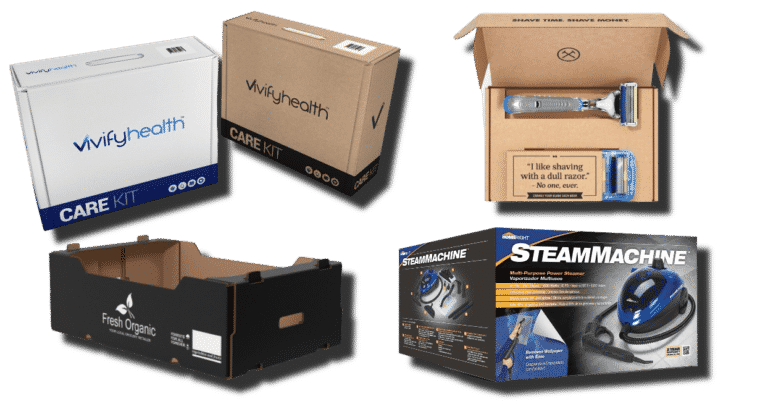

Versatility and Customization

Corrugated boxes are celebrated for their versatility. They can be custom-manufactured to fit any size, shape, or weight requirement, ensuring that products, regardless of their dimensions, can be securely packaged with minimal movement inside the box. This customizability extends to the printing and branding of the boxes, making them an effective marketing tool in addition to their primary function of protection.

Sustainability

One of the most compelling advantages of corrugated boxes is their sustainability. Made from renewable resources, primarily recycled paper and cardboard, these boxes can be recycled again after their lifecycle, reducing waste and the demand for raw materials. The recycling process for corrugated cardboard is efficient and widespread, contributing to its status as one of the most recycled materials in the world.

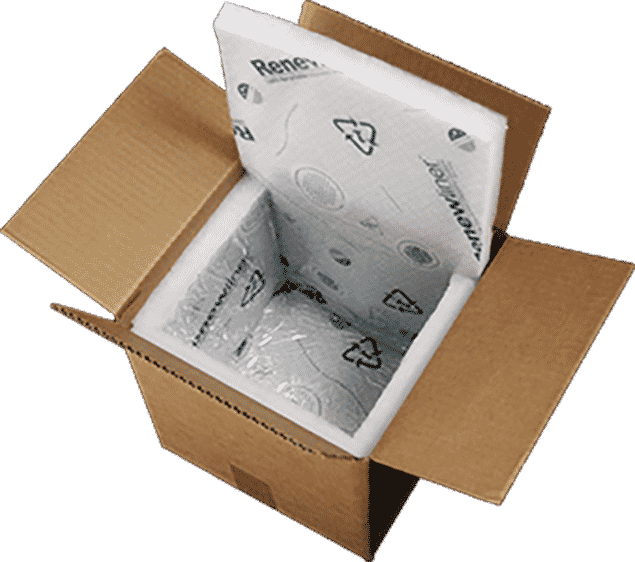

Durability and Protection

The durability of corrugated boxes is a key factor in their effectiveness. They are designed to resist tears, splits, and bursts, which can occur during handling and transit. The fluting within the cardboard also provides a cushion for the items inside, protecting against impacts. Furthermore, corrugated boxes can be treated with coatings or laminates to make them resistant to moisture, oil, and other environmental factors, thereby enhancing the protection they offer.

Cost-Effectiveness

Corrugated boxes are cost-effective, offering a high level of protection relative to their cost. They are lightweight, which reduces shipping costs, and their material and construction costs are lower compared to alternative packaging options. This cost-effectiveness makes corrugated boxes an attractive option for a wide range of industries, from e-commerce to retail and beyond.

Challenges and Considerations

While corrugated boxes are effective, there are considerations to keep in mind. The integrity of the box can be compromised by overloading, improper handling, or exposure to damp conditions. However, these challenges can be mitigated through proper design, handling, and storage practices.

Conclusion

In conclusion, corrugated boxes offer an effective solution for packaging needs across various industries. Their strength, flexibility, sustainability, and cost-effectiveness make them a superior choice for protecting goods during transit and storage. By leveraging the inherent benefits of corrugated boxes and adhering to best practices for their use, businesses can ensure the safety of their products while also contributing to environmental sustainability.

If you are interested in corrugated boxes, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Are Corrugated Boxes Effective?