Home » Applying the Four Ps of Marketing to Custom Packaging

Applying the Four Ps of Marketing to Custom Packaging

In the dynamic world of marketing, packaging plays a central role in shaping consumer perceptions and influencing purchasing decisions. Custom packaging offers a unique opportunity to leverage the timeless principles of the Four Ps of Marketing—Product, Price, Place, and Promotion—while embracing modern strategies for creating memorable brand experiences. In this blog, we’ll explore how custom packaging aligns with these four pillars, making it an essential component of modern marketing.

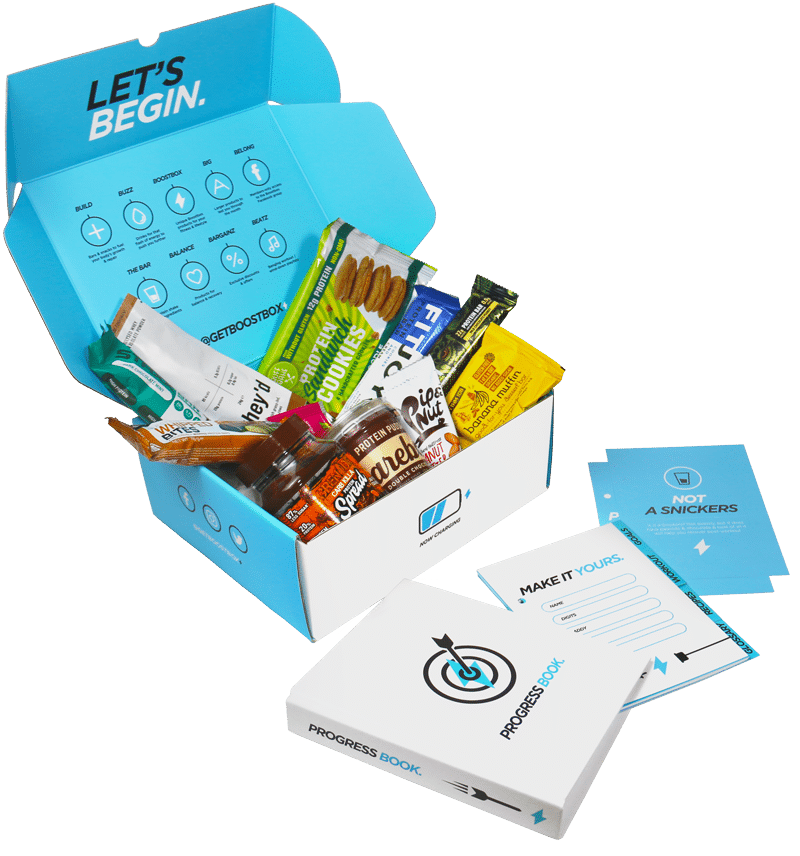

Product: Elevating Your Brand Through Packaging

In the context of custom packaging, “product” encompasses not only the item within but also the packaging itself. Your packaging should seamlessly extend the product experience and elevate its perceived value.

- Product Enhancement: Consider how your custom packaging enhances the overall product experience. It should be functional, aesthetically pleasing, and a reflection of your brand’s identity.

- Tailored Solutions: Custom packaging allows you to design packaging that perfectly fits the product, creating a seamless and visually appealing connection.

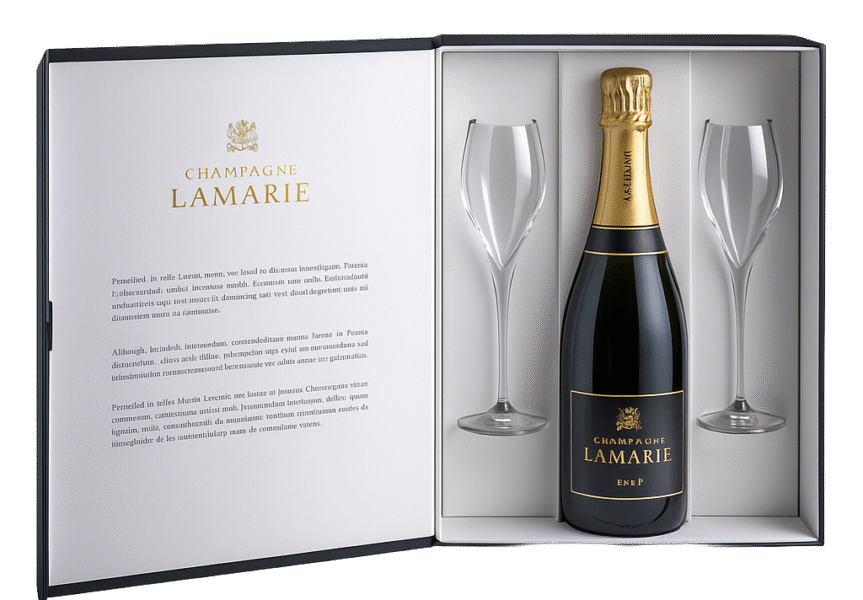

Price: The Packaging-Value Connection

“Price” goes beyond just setting a cost; it’s about the perceived value customers derive from your product. Custom packaging can significantly impact your pricing strategy.

- Perceived Value: High-quality, customized packaging can enhance the perceived value of your product, justifying a premium price.

- Cost Considerations: Be sure to factor in the cost of custom packaging materials and design when determining your pricing strategy to ensure it remains profitable.

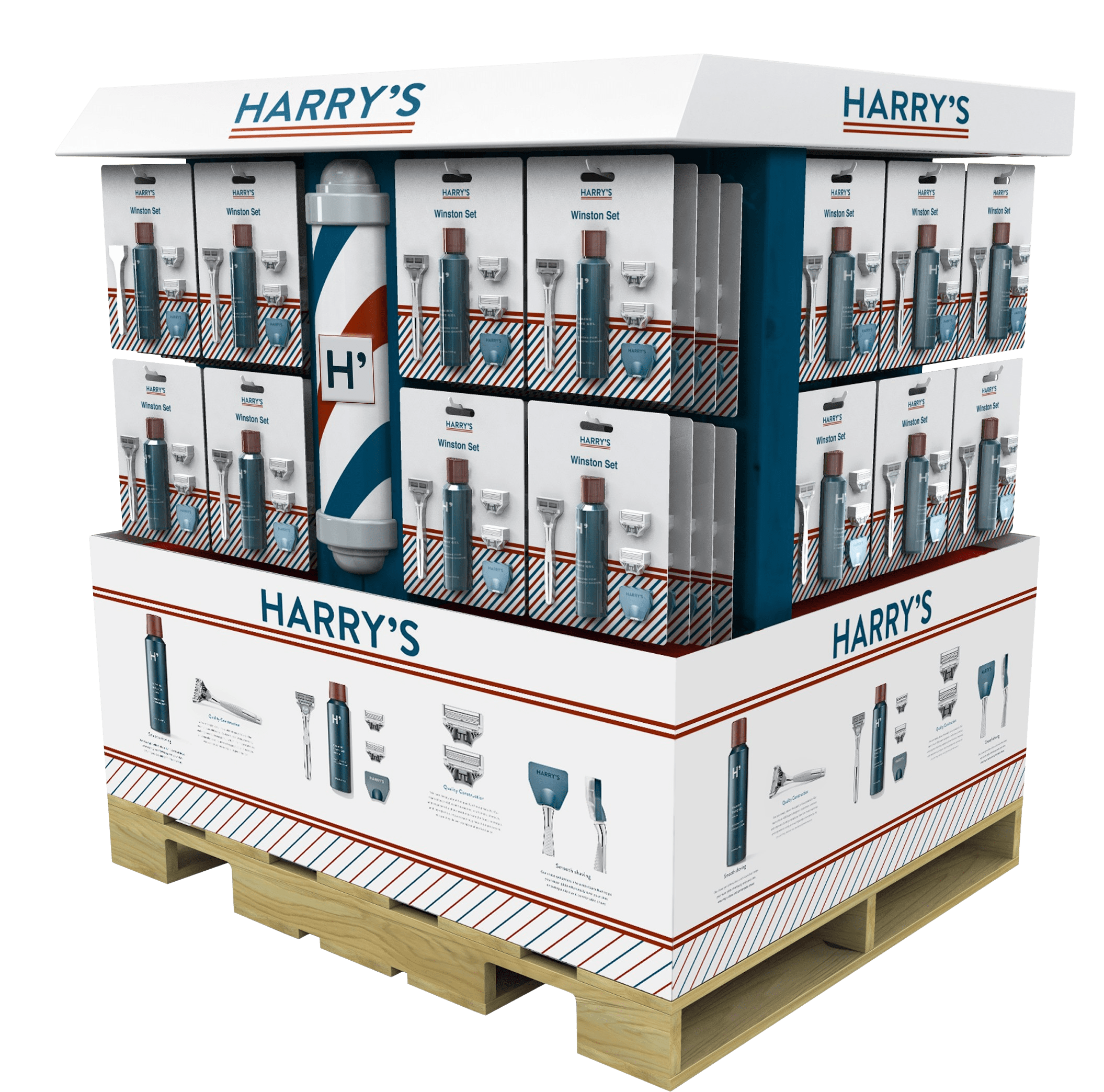

Place: Packaging Meets Distribution

The “place” element centers on distribution channels and accessibility. Custom packaging should align with your distribution strategy and the locations where your product is available.

- Distribution Channels: Consider how your custom packaging suits your distribution channels, especially in e-commerce, where unique packaging may be needed for shipping.

- Logistics Alignment: Ensure that your packaging aligns with the logistical requirements of efficiently delivering your product to customers.

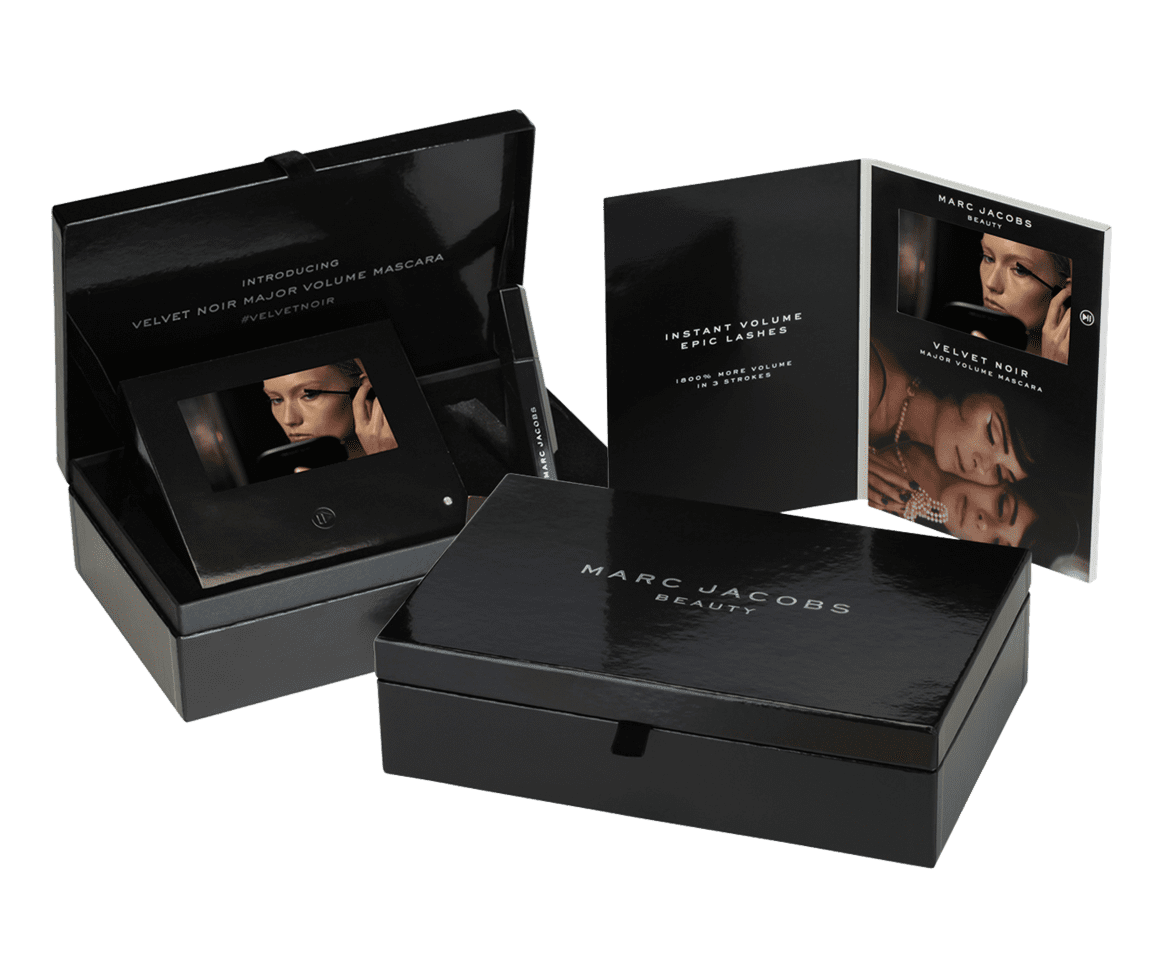

Promotion: Packaging as a Marketing Canvas

“Promotion” encompasses all the marketing activities aimed at promoting your product. Custom packaging is a potent promotional tool in itself.

- Brand Reinforcement: Utilize custom packaging to reinforce your brand identity, tell your brand’s story, and grab attention in physical stores or online marketplaces.

- Creative Branding: Think of your packaging as a canvas for creative branding and storytelling, making your product memorable to consumers.

Conclusion

In conclusion, custom packaging is not just a container for your product; it’s a strategic marketing tool that seamlessly aligns with the Four Ps of Marketing. It enhances product value, aligns with distribution channels, serves as a powerful promotional canvas, and creates unforgettable brand experiences. In the competitive marketplace of today, packaging your brand effectively can make all the difference, influencing consumer choices and building brand loyalty.

If you are interested in custom packaging, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Applying the Four Ps of Marketing to Custom Packaging

In the diverse world of retail and e-commerce, managing multiple Stock Keeping Units (SKUs) can be a daunting task, especially when it comes to packaging.

Why Co-Packaging Becomes Critical During the Holidays As the holiday season approaches, packaging teams are under pressure to deliver high volumes of promotional sets, combo

In the realm of product management, the relationship between packaging and storage is often overlooked, yet it is a critical aspect of operational efficiency and