Home » Balancing Graphics and Structure in POP Displays

Balancing Graphics and Structure in POP Displays

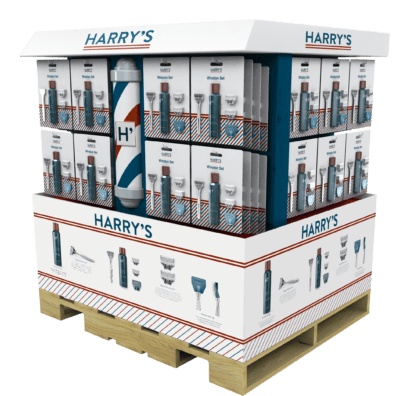

Point-of-purchase (POP) displays play a dual role in retail environments: they must capture attention with graphics while supporting products with reliable structure. If one side is overemphasized, the other suffers—eye-catching graphics on a weak structure can lead to product collapse, while overbuilt displays with poor graphics fail to drive sales. Successful POP design requires careful coordination between visual branding and engineering strength.

The Role of Graphics in POP Displays

Graphics carry the brand message and attract consumer attention in crowded retail aisles. Effective use of color, typography, and imagery transforms a standard corrugated display into a compelling marketing tool.

- Reinforces brand identity.

- Highlights product features or promotions.

- Differentiates products from competitors on the same shelf.

However, graphics must be placed with consideration of die lines, folds, and assembly points. A design that looks strong in concept may lose effectiveness if critical elements are cut or hidden during production.

Structural Integrity and Functionality

The best POP display design balances aesthetics with durability. Structural engineering ensures the display holds weight, withstands handling, and complies with retailer requirements.

- Load-bearing capacity: Displays must hold multiple units without sagging.

- Assembly efficiency: Designs should be easy to set up in stores.

- Retail compliance: Dimensions must fit within chain-specific guidelines.

Ignoring structure risks costly failures on the retail floor, from leaning displays to complete collapse.

Achieving Balance Between Graphics and Structure

- Collaborative design: Graphic and structural designers should work together from concept through prototype.

- Testing in real-world conditions: Simulate load, handling, and lighting before production.

- Material selection: Choose board grades and coatings that allow high-quality print while maintaining rigidity.

- Print-to-structure alignment: Ensure graphics align with folds, cutouts, and SKU placement.

Industry Examples

- Club stores: High-traffic environments demand bold graphics paired with strong pallet displays.

- Seasonal promotions: Graphics drive excitement, but structural resilience ensures displays last through extended campaigns.

- Cross-merchandising displays: Must hold different SKUs securely without compromising print impact.

POP Display Solutions with Brown Packaging

At Brown Packaging, we engineer POP displays that balance structural integrity with brand-forward graphics. From retail-ready pallet displays to seasonal floor stands, our team ensures your design attracts attention without sacrificing performance. Contact us to start planning your next POP display.

References

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

Shop! Association. (2021). Best Practices for In-Store Marketing and POP Displays. Retrieved from https://www.shopassociation.org

ASTM International. (2022). ASTM D642: Standard Test Method for Determining Compressive Resistance of Shipping Containers.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Balancing Graphics and Structure in POP Displays