Home » Edge Crush Test (ECT) Optimization for E-Commerce Shipments

Edge Crush Test (ECT) Optimization for E-Commerce Shipments

The Edge Crush Test (ECT) is a critical performance metric for corrugated boxes, directly correlating to stacking strength and load-bearing capacity. In the high-stress world of e-commerce shipping, where packages face frequent handling, multi-stop routes, and varying climates, optimizing ECT values without over-engineering is essential for cost efficiency and product protection.

Why ECT Matters in E-Commerce

- Stacking Strength: Determines how well boxes can withstand vertical loads in warehouse racking or trailer stacking.

- Material Efficiency: Allows engineers to achieve performance targets with lighter weight liners or mediums, reducing costs.

- Regulatory Alignment: Certain carriers and industry sectors specify minimum ECT ratings for compliance.

Balancing ECT and Basis Weight

- ECT vs. Mullen Burst: ECT measures column strength; Mullen measures resistance to puncture/tearing. E-commerce often favors ECT for stacked pallet loads.

- Lightweighting Strategies:

- Use high-performance recycled fiber blends to maintain stiffness.

- Incorporate higher-grade outer liners for localized reinforcement.

Design Variables That Influence ECT

- Flute Profile: B- and C-flutes offer different stiffness profiles. B-flute generally yields higher ECT for the same board weight.

- Adhesive Quality: Uniform glue lines prevent micro-buckling under compression.

- Moisture Resistance: High humidity can reduce ECT by up to 50%; moisture-resistant coatings help maintain performance.

Testing and Standards

- ASTM D642: Measures box compression strength.

- TAPPI T839: Determines edgewise compressive strength of corrugated fiberboard using the clamp method.

- ISTA Series: Full-scale distribution simulation, including drop, vibration, and compression under varying conditions.

Optimization in Practice

- Case Example: Switching from 44 ECT double-wall to 32 ECT single-wall with enhanced flute medium reduced material cost by 14% without increasing damage claims in a 90-day trial.

- Prototyping: Lab ECT data should be validated through route-specific field testing before large-scale rollout.

References

ASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://www.astm.org/d0642-15.html

Technical Association of the Pulp and Paper Industry. (2018). TAPPI T839 om-18: Edgewise compressive strength of corrugated fiberboard using the clamp method. TAPPI. https://www.tappi.org/content/store/shared/T839.html

International Safe Transit Association. (2018). ISTA 6-Series transit tests. ISTA. https://ista.org/

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Home » Edge Crush Test (ECT) Optimization for E-Commerce Shipments

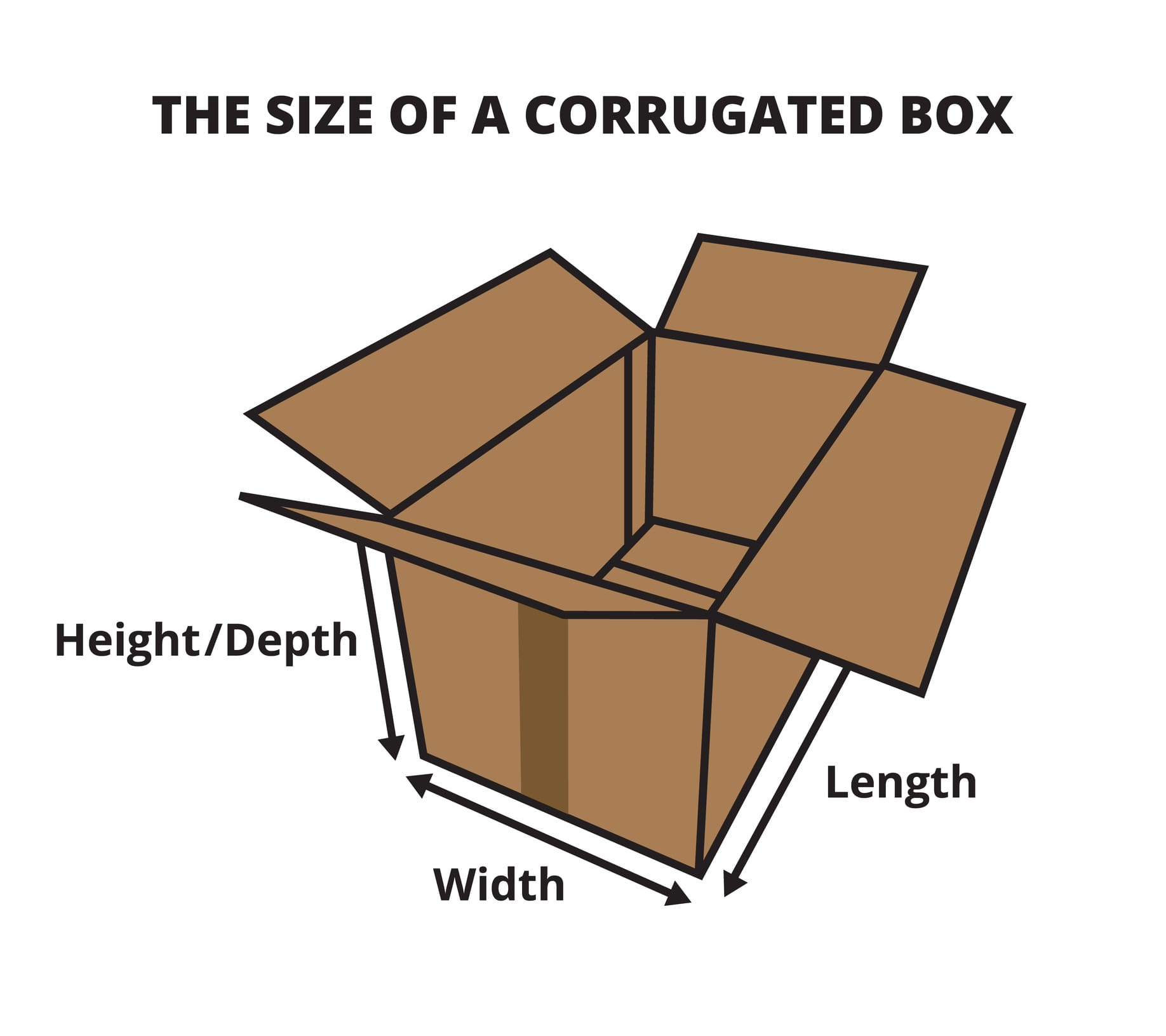

Structurally designing your corrugated box involves understanding the specific requirements of your product and applying principles of material science and engineering to ensure optimal protection, efficiency, and cost-effectiveness. This process requires careful consideration of the box’s dimensions, material grade, flute type, and the intended use to create a packaging solution that meets both logistical and aesthetic needs. Understanding the Basics of Corrugated Boxes Before diving into the design process, it’s important to grasp the fundamental components of a corrugated box: Fluting: The wavy layer of corrugated paper that provides cushioning and strength. The size, type and the material of the flute affect the box’s compression strength, stacking strength, and crush resistance. Linerboards: Flat sheets of paper that sandwich the fluting, contributing to the box’s durability and structural integrity. Box Types: Common configurations include the Regular Slotted Container (RSC), Full Overlap (FOL), and Die-Cut designs, each offering different benefits in terms of protection and assembly efficiency. Step 1: Assess Product Requirements Start by evaluating the weight, dimensions, and fragility of the product. Consider any additional space needed for internal packaging materials like bubble wrap or foam inserts, which provide extra protection for delicate items. This assessment will guide the choice of box size and strength needed to ensure safe transport and storage. Step 2: Select Material and Flute Type Choose the appropriate material grade and flute type based on the product’s weight and the level of protection required. For lightweight items, a single-wall box with smaller flutes like B or C may suffice. Heavier or more fragile items may require double-wall or triple-wall boxes with larger flutes like A or BC for increased cushioning and strength. The Edge Crush Test (ECT) rating of the cardboard is a critical factor here, indicating the box’s ability to withstand external pressures. Step 3: Design for Efficiency and Sustainability Efficiency in packaging not only reduces material costs but also minimizes waste, contributing to sustainability. Design your box to fit your product snugly while allowing for minimal extra packaging material. Consider using recyclable materials and designing for ease of recycling after use, such as avoiding mixed materials that are difficult to separate. Step 4: Prototype and Test Once the initial design is established, create a prototype of your box. This allows for hands-on testing to ensure the box meets your requirements in terms of size, strength, and functionality. Conduct tests that mimic real-world handling, shipping, and stacking scenarios to identify any structural weaknesses or design flaws. Step 5: Customization and Branding Customization isn’t just about aesthetics; it can also enhance the box’s structural integrity. For example, die-cut inserts not only secure products within the box but also add rigidity to the structure. Use the exterior for branding, but ensure that any printing or customization does not compromise the box’s strength. Step 6: Iterate Based on Feedback Use feedback from the testing phase to refine your design. This may involve adjusting dimensions, changing the flute type, or reevaluating the material grade. Iteration is a crucial step in optimizing the design for both protection and cost. Conclusion Structurally designing a corrugated box is a detailed process that blends science, engineering, and aesthetics. It requires a deep understanding of the product needs, material properties, and the logistical demands of shipping and handling. By following these steps and focusing on both function and form, you can develop a corrugated box that not only protects your product but also enhances your brand’s presentation and sustainability efforts. If you are interested in custom structurally designed corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Why Packaging Automation Compatibility Matters As more fulfillment centers, contract packagers, and manufacturers turn to automation, packaging that isn’t compatible with machinery becomes a costly bottleneck. From misfeeds on case erectors to jams in packing stations, poorly designed corrugated boxes slow down operations, increase error rates, and limit throughput. For high-volume brands and logistics operations, automation-compatible packaging isn’t optional—it’s a core part of the system. Common Points of Failure with Corrugated in Automation Systems Automation often fails not because the equipment is faulty, but because the packaging isn’t designed for machine handling. Common issues include: Poor dimensional tolerance: If the box flaps don’t align cleanly, case erectors and tapers will jam. Low board rigidity: Boxes made from lightweight corrugated collapse during suction or robotic pick-and-place. Inconsistent slotting and scoring: Uneven folds confuse sensors or result in skewed box geometry. Incompatible closure style: Designs like auto-lock bottoms or complex folds may not be machine-erectable. Structural Design Principles for Automation Compatibility ✔ Stick to Clean, Repeatable FormatsRSC and FOL boxes with precision scoring are ideal for case erectors and tapers. Avoid overly intricate die cuts or asymmetrical flaps unless they’re downstream of automation. ✔ Use Consistent Die-Lines and Slot DepthsMaintain tight tolerances on slot depth, flap width, and glue tabs. Variability in cutting leads to misfeeds on erectors or case packers. ✔ Right-Size the Box for ConsistencyBoxes should hold contents securely with minimal void fill. Automated packout systems are most efficient when the box requires no manual fitting or adjustment. ✔ Add Automation-Friendly FeaturesIf machine-packing is in use, design inserts or partitions that can be preloaded or nested without human intervention. Consistent entry points and fitment are key. Material Considerations ✔ Choose Higher Rigidity Board GradesBoards with better stiffness (e.g., 44 ECT or 275#) maintain shape during pick-and-place and resist deformation in automated erecting. ✔ Use Coatings Where NeededFor packaging that passes through friction belts or vacuum suction, a clay-coated or high-slip surface may improve feed reliability. ✔ Avoid WarpPoor storage conditions or low-quality material lead to box warp, which ruins automation compatibility. Store flat and dry, and use high-quality stock. Don’t Forget Print RegistrationAutomation often uses machine vision to scan barcodes or orientation markers. Digital or flexo-printed registration cues must be in consistent locations, with sharp contrast and no ink bleed. Variable data printing can also assist with lot tracking in automated pick-pack systems. Benefits of Automation-Compatible Corrugated Faster throughput with fewer jams or stoppages Lower labor costs due to minimal hand correction Better reliability in high-speed fulfillment environments Scalability when expanding SKUs or entering new distribution channels Final ThoughtsCorrugated packaging isn’t just a vessel—it’s a mechanical component in an automated system. Brands that optimize their box design, material spec, and print layout for automation reduce errors, increase efficiency, and lower cost per shipment. If you’re designing packaging for automation or reworking a manual process, Brown Packaging can help engineer corrugated solutions that perform in real-world fulfillment lines. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

The Edge Crush Test (ECT) is a critical performance metric for corrugated boxes, directly correlating to stacking strength and load-bearing capacity. In the high-stress world of e-commerce shipping, where packages face frequent handling, multi-stop routes, and varying climates, optimizing ECT values without over-engineering is essential for cost efficiency and product protection. Why ECT Matters in E-Commerce Stacking Strength: Determines how well boxes can withstand vertical loads in warehouse racking or trailer stacking. Material Efficiency: Allows engineers to achieve performance targets with lighter weight liners or mediums, reducing costs. Regulatory Alignment: Certain carriers and industry sectors specify minimum ECT ratings for compliance. Balancing ECT and Basis Weight ECT vs. Mullen Burst: ECT measures column strength; Mullen measures resistance to puncture/tearing. E-commerce often favors ECT for stacked pallet loads. Lightweighting Strategies: Use high-performance recycled fiber blends to maintain stiffness. Incorporate higher-grade outer liners for localized reinforcement. Design Variables That Influence ECT Flute Profile: B- and C-flutes offer different stiffness profiles. B-flute generally yields higher ECT for the same board weight. Adhesive Quality: Uniform glue lines prevent micro-buckling under compression. Moisture Resistance: High humidity can reduce ECT by up to 50%; moisture-resistant coatings help maintain performance. Testing and Standards ASTM D642: Measures box compression strength. TAPPI T839: Determines edgewise compressive strength of corrugated fiberboard using the clamp method. ISTA Series: Full-scale distribution simulation, including drop, vibration, and compression under varying conditions. Optimization in Practice Case Example: Switching from 44 ECT double-wall to 32 ECT single-wall with enhanced flute medium reduced material cost by 14% without increasing damage claims in a 90-day trial. Prototyping: Lab ECT data should be validated through route-specific field testing before large-scale rollout. ReferencesASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://www.astm.org/d0642-15.htmlTechnical Association of the Pulp and Paper Industry. (2018). TAPPI T839 om-18: Edgewise compressive strength of corrugated fiberboard using the clamp method. TAPPI. https://www.tappi.org/content/store/shared/T839.htmlInternational Safe Transit Association. (2018). ISTA 6-Series transit tests. ISTA. https://ista.org/ (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts