Home » How Packaging Suppliers Streamline Rigid Boxes for Retail

How Packaging Suppliers Streamline Rigid Boxes for Retail

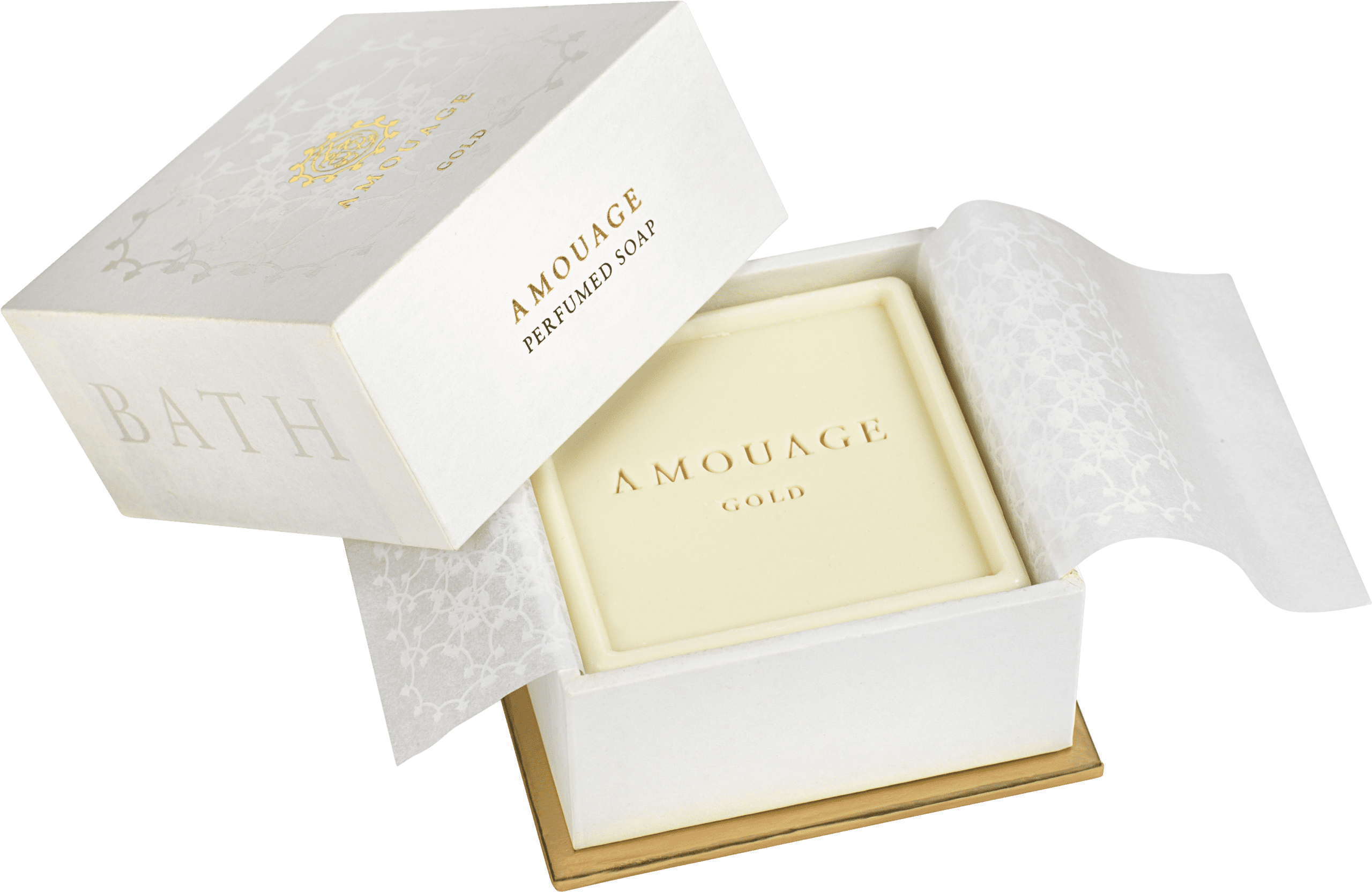

Rigid boxes are the premium standard in packaging—perfect for luxury products, high-end electronics, skincare, and gift sets. But creating a beautiful rigid box is only part of the process. To succeed in retail, your packaging must also meet strict retailer requirements, ensure supply chain efficiency, and deliver an exceptional unboxing experience for the customer.

That’s where the right packaging supplier makes a real difference. From early design support to final delivery, a knowledgeable supplier helps streamline every stage of your rigid box project—so you can get to market faster, stay compliant, and reduce costly packaging missteps.

Aligning Structural Design with Retail Requirements

Every major retailer—Target, Sephora, Walmart, Ulta, Costco—has its own set of packaging specs. A qualified packaging supplier understands these standards and helps ensure your rigid box design meets them from day one.

They’ll help you:

- Choose the right box dimensions and formats for shelf compatibility

- Design boxes that are stackable, protective, and easy to merchandise

- Comply with weight, display, and material restrictions

- Avoid common issues that cause costly rejections

✅ Saves time on approvals

✅ Prevents repackaging or reworking

✅ Positions you for smoother retailer onboarding

Coordinating Print, Finishes & Branding for Consistency

Retail-ready rigid boxes need to stand out visually while maintaining strict brand consistency across SKUs and product lines. A packaging supplier can oversee the full process—ensuring your logo placement, colors, and finishes are correct on every box, no matter the quantity.

They’ll also advise you on:

- Matching existing packaging elements

- Choosing finishes that enhance shelf appeal (foil, embossing, soft-touch)

- Selecting print methods (offset, digital) that meet timeline and volume needs

- Incorporating interior printing or custom inserts for elevated presentation

✅ Elevates product value and brand perception

✅ Supports promotional versions or line extensions

✅ Helps meet retailer expectations for premium packaging

Managing Production and Lead Times Efficiently

One of the biggest challenges with rigid boxes is the longer production time compared to other packaging formats. Working with a supplier means you’ll have production timelines mapped out, risks flagged early, and inventory timed to meet retail delivery windows.

Suppliers help with:

- Coordinating multiple components (base, lid, insert, printing)

- Managing long-lead finishes like embossing or foil

- Setting expectations for inventory drop dates

- Avoiding bottlenecks caused by fragmented communication

✅ Helps you hit critical launch dates

✅ Reduces delays from scattered sourcing

✅ Provides transparency and timeline accountability

Offering Samples, Prototypes, and Pre-Press Checks

Before full production, your supplier can create physical samples or digital proofs to ensure everything—from structure to graphics to fit—is perfect. This step is especially important when dealing with multiple SKUs or new retail accounts.

What they provide:

- Full production mockups or white samples for review

- Guidance on packaging dielines and layout

- Print file proofing for color, resolution, and layout accuracy

- Pre-production testing for inserts, closures, and durability

✅ Reduces costly production mistakes

✅ Ensures fit and finish meets expectations

✅ Speeds up retailer approval and compliance

Supporting Fulfillment, Assembly & Shipping Optimization

Many retailers require fully assembled, filled, or shelf-ready packaging. Your supplier can often assist with kitting, packout, or coordination with your co-packer or fulfillment partner to make sure your rigid boxes are ready to go right out of the box.

They can help:

- Pre-build boxes with inserts, tissue, and product placement

- Label, barcode, or shrink-wrap to meet retailer specs

- Pack efficiently for pallet optimization and damage prevention

- Prepare packaging to meet e-commerce AND retail requirements

✅ Reduces labor and fulfillment complexity

✅ Delivers a true turnkey solution

✅ Increases speed to shelf or customer

Staying Compliant with Regulations and Sustainability Trends

Retailers expect packaging to meet increasing standards for sustainability, labeling, and material sourcing. A knowledgeable supplier helps you stay ahead of compliance and align with retail trends.

Support may include:

- Guidance on recyclable or eco-friendly materials

- Compliance with food-safe or cosmetic-safe materials

- Material reduction strategies for reduced carbon footprint

- Providing certifications or documentation for retail requirements

✅ Positions your brand as forward-thinking

✅ Prevents compliance delays or rejections

✅ Helps meet retailer sustainability scorecards

Final Thoughts

Rigid boxes can elevate your product—but only when they’re backed by the right strategy, materials, and execution. A reliable packaging supplier helps you do more than just create a beautiful box—they streamline the entire process for retail readiness, brand consistency, and supply chain success.

Need help getting your rigid boxes ready for retail?

We’ll guide you through every step—from design and printing to compliance and delivery—to help you launch with confidence.

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping,

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Home » How Packaging Suppliers Streamline Rigid Boxes for Retail

Launching a product in a retail chain or club store is a significant milestone for any brand. However, this process can come with challenges, particularly when it comes to meeting specific packaging guidelines. Non-compliance with these guidelines often leads to product rejection, a setback that can be costly both in terms of time and resources. This blog post lists some of the biggest mistake’s brands make in their packaging, which lead to rejection by retail chains and club stores. Ignoring Specific Packaging Requirements Each retail chain or club store has its own set of packaging requirements. Common oversights include: Size and Dimension Neglect: Packaging that is too large or too small for standard shelving can lead to rejection. Material Restrictions: Some retailers have restrictions on certain packaging materials, often for sustainability reasons. Inadequate Packaging Strength: Packaging that doesn’t provide sufficient protection to withstand the retail environment. Inadequate Branding and Design Packaging that fails to stand out or communicate the brand effectively can be detrimental. Poor Visibility: Designs that don’t catch the consumer’s eye or blend in too much with competitors. Confusing Messaging: Packaging that fails to clearly communicate what the product is and its benefits. Non-Compliance with Branding Guidelines: Retailers may have specific branding guidelines that need to be adhered to. Failure to Consider User Experience User experience is paramount, and overlooking it can lead to product rejection. Difficult to Open or Use: Packaging that is consumer-unfriendly can be a significant deterrent. Lack of Information: Essential information like usage instructions, ingredients, or warnings needs to be clear and easily accessible. Non-Adherence to Regulatory Compliance Not complying with legal and regulatory requirements is a serious error. Missing or Incorrect Labeling: This includes nutritional information, ingredient lists, and safety warnings. Barcode Issues: Barcodes that are incorrectly placed or hard to scan can lead to logistical issues. Underestimating the Importance of Sustainability Sustainability is increasingly becoming a priority for retailers and consumers alike. Non-Recyclable Materials: Using materials that are not eco-friendly can be a reason for rejection. Excessive Packaging: Over-packaging not only wastes resources but can also be looked down upon by eco-conscious retailers and consumers. Overlooking Transportation and Storage Requirements Failing to consider how a product is transported and stored can lead to packaging damages and subsequent rejection. Poorly Designed for Shipping: Packaging that doesn’t protect the product during transit. Storage Inefficiency: Packaging that isn’t designed for efficient storage can be problematic in the retail space. Ignoring Cost-Effectiveness Retailers are always looking for products that offer them a good margin. Overpriced Packaging: Excessively expensive packaging can drive up the product cost, making it less attractive to retailers. Inefficient Packaging Process: Packaging that is costly or time-consuming to assemble can also be a drawback. If you are looking interested in retail packaging, contact Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Retail Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

POP displays must balance eye-catching branding with structural integrity. Inadequate load-bearing design can result in product sagging, leaning, or complete collapse, which not only risks product loss but also damages retailer confidence. By applying engineering principles, testing protocols, and correct material selection, brands can maximize display stability without unnecessary cost. Understanding Load-Bearing Capacity Static Load vs. Dynamic Load: Static load refers to the total weight a display can hold without movement. Dynamic load accounts for forces during handling, stocking, and customer interaction. Failure Modes: Panel buckling, shelf deflection, joint separation, and base collapse are the most common failure points. Material Selection Corrugated Board Strength: Flute profile (B, C, E, or BC) impacts stiffness and stacking strength. Higher ECT boards increase vertical load capacity but also affect cost and weight. Coatings and Laminates: Water-resistant coatings prevent fiber weakening in humid environments. Laminates can increase rigidity but may impact recyclability. Structural Reinforcements Double-Wall Shelving: For heavier products such as beverages or canned goods. Internal Braces: Die-cut supports hidden behind the graphic panels for increased stability. Base Skids: Distributes load more evenly to prevent floor contact wear and pallet jack damage. Design and Geometry Weight Distribution: Heavier SKUs should be placed at lower tiers to reduce tipping risk. Joint Engineering: Lock tabs, glue flaps, and interlocking slots improve structural stability. Shear Resistance: Cross-bracing and panel alignment reduce the risk of diagonal collapse. Testing Protocols ASTM D642: Measures compression strength to determine safe stacking loads. ISTA 3A & 6-Series: Simulates real-world handling, vibration, and impact. Shelf Deflection Tests: Measures how much a shelf bends under load over time. Best Practices Always design for at least 25% higher load capacity than the expected maximum product weight. Validate prototypes under realistic load and environmental conditions before production. Balance cost-to-performance ratio — over-engineering increases cost without visible retail benefit. References ASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://www.astm.org/d0642-15.htmlInternational Safe Transit Association. (2018). ISTA 3A general simulation performance test for packaged-products for parcel delivery system shipment. ISTA. https://ista.org/International Safe Transit Association. (2018). ISTA 6-Series transit tests. ISTA. https://ista.org/ (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts

In the competitive world of retail, effective packaging can make all the difference. If your product finds itself on the bottom shelf, it’s essential to invest in packaging that not only protects your product but also captures the attention of shoppers. In this comprehensive guide, we’ll explore how to package your product for retail and make it stand out, even when placed on the bottom shelf. Know Your Target Audience Eye-Catching Design Optimize Packaging Size Clear Product Information Use Unique Shapes Incorporate Interactive Elements Highlight Key Selling Points Utilize Color Psychology Test Store Layouts Collaborate with Retailers Understanding the Significance of Shelf Placement The placement of your product on the retail shelf can greatly impact its visibility and sales. Bottom shelf placement is a common challenge, as it may be less eye-catching than eye-level or top-shelf locations. However, with strategic packaging and design, you can overcome this challenge and make your product shine. Know Your Target Audience Understanding your target audience is the first step in creating effective packaging. What appeals to your potential customers? What are their preferences and priorities? Tailor your packaging design to resonate with your target demographic. Eye-Catching Design Invest in a visually appealing packaging design that grabs attention. Use vibrant colors, compelling graphics, and high-quality images to make your product stand out. Ensure that your packaging reflects the essence of your brand and the uniqueness of your product. Optimize Packaging Size Consider the dimensions of your packaging. If your product is on the bottom shelf, it should be easy to reach and handle. Avoid oversized or bulky packaging that can be challenging for customers to access. Clear Product Information Provide clear and concise product information on the packaging. Shoppers should be able to quickly understand what your product is, its key features, and its benefits. Use legible fonts and make essential details easily visible. Use Unique Shapes Consider unique packaging shapes that distinguish your product from the competition. Unconventional shapes can pique curiosity and draw shoppers’ attention. However, ensure that the shape aligns with your brand and product identity. Incorporate Interactive Elements Interactive packaging features can engage shoppers and make your product memorable. This might include peel-and-reveal labels, cut-out windows, or embossed textures that invite touch and exploration. Highlight Key Selling Points Identify your product’s key selling points and prominently feature them on the packaging. Whether it’s eco-friendly materials, product quality, or a special promotion, make sure these attributes are clearly communicated. Utilize Color Psychology Harness the power of color psychology to evoke specific emotions and associations. Different colors can convey trust, excitement, or relaxation, depending on your brand and product message. Test Store Layouts Visit retail stores where your product is sold and observe how the bottom shelves are arranged. Request shelf adjustments or rearrangements if necessary to ensure better visibility. Collaborate with Retailers Build strong relationships with retailers and collaborate on promotional opportunities. Retailers may provide signage, displays, or end-cap placements that can enhance your product’s visibility. Conclusion Effective packaging is a crucial element in making your product stand out on the bottom shelf of retail stores. By understanding your target audience, investing in eye-catching design, optimizing packaging size, providing clear product information, using unique shapes, incorporating interactive elements, highlighting key selling points, leveraging color psychology, testing store layouts, and collaborating with retailers, you can increase your product’s chances of success, even in a less prominent location. Remember that packaging is not just a protective shell; it’s a powerful marketing tool that can influence shoppers’ buying decisions. With thoughtful and strategic packaging, you can make your product a standout success on any shelf. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts