Home » How Litho Labels Elevate Rigid Box Packaging

How Litho Labels Elevate Rigid Box Packaging

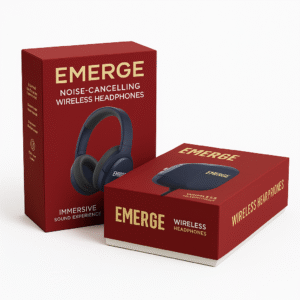

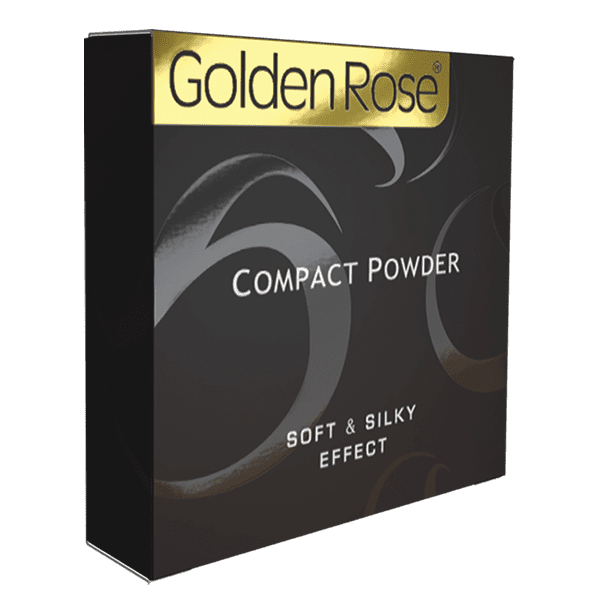

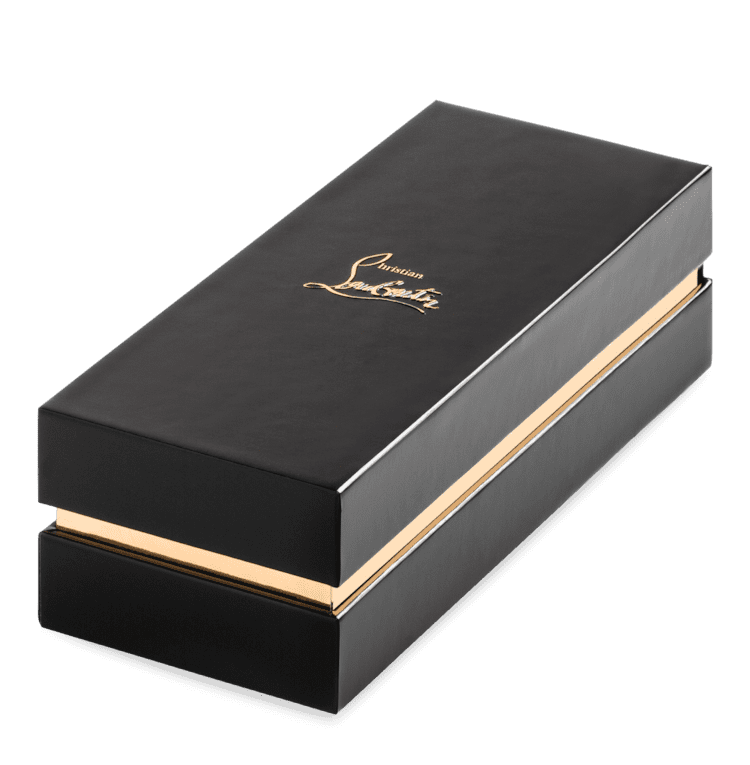

Rigid boxes are known for their durability, structure, and high-end feel—but what truly gives them their luxury appeal is the finish. That polished, vibrant exterior you see on high-end packaging? That’s often thanks to a litho label—a printed sheet that’s mounted to the box surface to deliver rich detail, bold color, and elevated texture.

In this blog, we’ll explore what litho labels are, why they’re commonly used on rigid boxes, and how they can transform your packaging into a premium brand experience.

What Is a Litho Label?

A litho label (short for lithographic label) is a high-resolution printed sheet—usually made from paper or specialty stock—that’s adhered to the surface of a rigid box using glue or mounting equipment.

Litho labels are produced using offset (lithographic) printing, which is known for:

- Crisp detail

- Vivid color accuracy

- Smooth gradients and photo-quality imagery

- Compatibility with coatings like gloss, matte, or soft-touch

Once printed, the label is mounted onto the rigid box, giving it a refined appearance that can’t be achieved through direct-to-board printing.

Why Litho Labels Are Ideal for Rigid Boxes

Rigid boxes are made from thick, dense paperboard (often chipboard), which isn’t suitable for high-quality direct printing. Litho labels solve that by providing a premium printed surface that wraps the box cleanly.

Benefits of Litho Labels on Rigid Boxes:

✅ Photo-Quality Graphics

Perfect for showcasing detailed artwork, branding, or imagery that reinforces luxury positioning.

✅ Wide Range of Finishes

Litho labels can be laminated or coated with gloss, matte, soft-touch, or spot UV, depending on your aesthetic.

✅ Tactile Enhancement

Embossing, debossing, and foil stamping can be applied on top of the label for even more depth and visual interest.

✅ Consistent Quality Across Batches

Offset printing offers high repeatability, making litho labels ideal for brands that demand precision and consistency.

Popular Applications for Litho-Labeled Rigid Boxes

You’ll find litho labels in nearly every premium category, especially where first impressions and unboxing matter.

Common uses include:

- Cosmetics & skincare kits

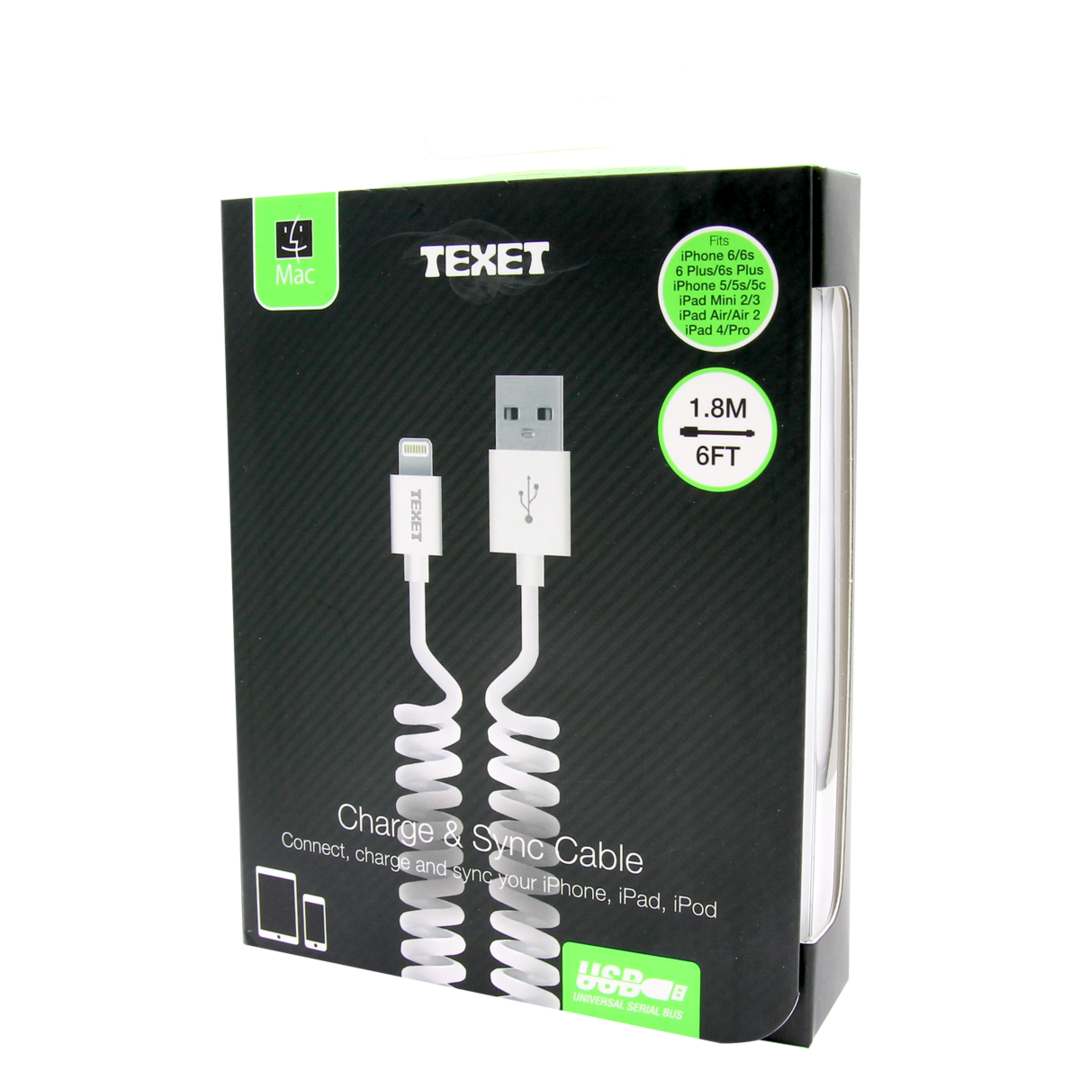

- Premium electronics packaging

- Subscription or influencer boxes

- High-end spirits or beverage boxes

- Luxury fashion or accessories

- Gift boxes and holiday promotions

Whether displayed in-store or shipped DTC, litho-labeled rigid boxes instantly elevate the perceived value of the product inside.

Design Freedom and Branding Possibilities

Because litho labels are printed before they’re applied, they give you more flexibility in design than other packaging types. You can:

- Use full-bleed artwork and photo backgrounds

- Add intricate patterns or subtle gradients

- Include metallic inks or layered finishes

- Create seamless designs across lids and bases

This allows your packaging to act as an extension of your brand—not just a container, but a premium visual statement.

When Should You Use Litho Labels?

If you’re investing in rigid box packaging and want to maximize visual impact, litho labels are the industry standard. They’re the right choice when:

- Your brand prioritizes premium presentation

- You need high-definition imagery or color matching

- Your packaging will be seen in high-end retail environments

- You’re building a luxury unboxing experience for influencers or direct customers

For mid-range or mass-market packaging, simpler wraps or direct-to-board printing may suffice—but when presentation drives perception, litho-labeled rigid boxes deliver.

Final Thoughts

Litho labels bring rigid boxes to life. They combine the strength and structure of rigid packaging with the visual impact of high-end print finishes, making them a top choice for brands that want to stand out on the shelf—and in customers’ hands.

Ready to create a premium rigid box with litho labeling?

We’ll help you design the perfect combination of structure, print, and finish to match your product’s value and your brand’s voice.

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the

Home » How Litho Labels Elevate Rigid Box Packaging

Rigid boxes are known for their durability, structure, and high-end feel—but what truly gives them their luxury appeal is the finish. That polished, vibrant exterior you see on high-end packaging? That’s often thanks to a litho label—a printed sheet that’s mounted to the box surface to deliver rich detail, bold color, and elevated texture. In this blog, we’ll explore what litho labels are, why they’re commonly used on rigid boxes, and how they can transform your packaging into a premium brand experience. What Is a Litho Label? A litho label (short for lithographic label) is a high-resolution printed sheet—usually made from paper or specialty stock—that’s adhered to the surface of a rigid box using glue or mounting equipment. Litho labels are produced using offset (lithographic) printing, which is known for: Crisp detail Vivid color accuracy Smooth gradients and photo-quality imagery Compatibility with coatings like gloss, matte, or soft-touch Once printed, the label is mounted onto the rigid box, giving it a refined appearance that can’t be achieved through direct-to-board printing. Why Litho Labels Are Ideal for Rigid Boxes Rigid boxes are made from thick, dense paperboard (often chipboard), which isn’t suitable for high-quality direct printing. Litho labels solve that by providing a premium printed surface that wraps the box cleanly. Benefits of Litho Labels on Rigid Boxes: ✅ Photo-Quality GraphicsPerfect for showcasing detailed artwork, branding, or imagery that reinforces luxury positioning. ✅ Wide Range of FinishesLitho labels can be laminated or coated with gloss, matte, soft-touch, or spot UV, depending on your aesthetic. ✅ Tactile EnhancementEmbossing, debossing, and foil stamping can be applied on top of the label for even more depth and visual interest. ✅ Consistent Quality Across BatchesOffset printing offers high repeatability, making litho labels ideal for brands that demand precision and consistency. Popular Applications for Litho-Labeled Rigid Boxes You’ll find litho labels in nearly every premium category, especially where first impressions and unboxing matter. Common uses include: Cosmetics & skincare kits Premium electronics packaging Subscription or influencer boxes High-end spirits or beverage boxes Luxury fashion or accessories Gift boxes and holiday promotions Whether displayed in-store or shipped DTC, litho-labeled rigid boxes instantly elevate the perceived value of the product inside. Design Freedom and Branding Possibilities Because litho labels are printed before they’re applied, they give you more flexibility in design than other packaging types. You can: Use full-bleed artwork and photo backgrounds Add intricate patterns or subtle gradients Include metallic inks or layered finishes Create seamless designs across lids and bases This allows your packaging to act as an extension of your brand—not just a container, but a premium visual statement. When Should You Use Litho Labels? If you’re investing in rigid box packaging and want to maximize visual impact, litho labels are the industry standard. They’re the right choice when: Your brand prioritizes premium presentation You need high-definition imagery or color matching Your packaging will be seen in high-end retail environments You’re building a luxury unboxing experience for influencers or direct customers For mid-range or mass-market packaging, simpler wraps or direct-to-board printing may suffice—but when presentation drives perception, litho-labeled rigid boxes deliver. Final Thoughts Litho labels bring rigid boxes to life. They combine the strength and structure of rigid packaging with the visual impact of high-end print finishes, making them a top choice for brands that want to stand out on the shelf—and in customers’ hands. Ready to create a premium rigid box with litho labeling?We’ll help you design the perfect combination of structure, print, and finish to match your product’s value and your brand’s voice. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Rigid Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Rigid boxes, known for their durability and premium appearance, are a popular choice for packaging high-end products. However, the perception of being expensive can deter some businesses from utilizing them. In this detailed blog, we will explore effective strategies to ensure that you don’t break the bank when using rigid boxes for your packaging needs. With the right approach, you can enjoy the benefits of rigid boxes without exceeding your budget. Opt for Standard Sizes Customization often adds to the cost of rigid boxes. To save money, consider using standard box sizes whenever possible. Standard sizes are readily available, which can reduce production costs and lead times. If your product can fit into a standard-sized box without compromising protection or presentation, it’s a cost-effective choice. Choose Simple Designs Intricate and complex designs, such as embossing, debossing, or intricate patterns, can significantly increase the cost of rigid boxes. Simplify your design to include only essential branding elements and graphics. A minimalist approach can be just as impactful and cost-effective. Use Single-Color Printing If branding is crucial but you want to keep costs down, consider using single-color printing. A single color, especially in a bold and striking shade, can effectively convey your brand identity without the expense of full-color printing. This approach not only saves on printing costs but also creates an elegant and eye-catching look. Bulk Ordering Economies of scale come into play when ordering larger quantities of rigid boxes. Manufacturers often offer discounts for bulk orders. Evaluate your packaging needs and consider ordering a larger quantity upfront if it aligns with your long-term packaging requirements. This can result in significant cost savings per box. Utilize Stock Materials Custom materials, such as unique textures or specialized finishes, can escalate the cost of rigid boxes. Choosing stock materials that are readily available and in common use can help lower costs. Stock materials are usually more affordable because they are produced in larger quantities. Consolidate Packaging Components Incorporate multiple packaging components into a single rigid box. For example, you can include a foam insert or molded pulp tray within the box to hold and protect the product. This eliminates the need for separate packaging components and can save on overall packaging costs. Explore Different Box Styles Consider alternative rigid box styles that may be more cost-effective while still providing the desired level of protection and presentation. For instance, a hinged lid box or a magnetic closure box may be more budget-friendly than a traditional two-piece rigid box. Seek Multiple Quotes Don’t settle for the first manufacturer or supplier you come across. Seek quotes from multiple sources to compare pricing, quality, and lead times. This competitive approach can help you secure a cost-effective deal without compromising on quality. Sustainable Choices Many businesses are now prioritizing eco-friendly packaging. Choosing sustainable materials for your rigid boxes, such as recycled cardboard or FSC-certified paperboard, can not only align with your environmental values but also sometimes come at a lower cost. Conclusion Rigid boxes offer a premium and durable packaging solution that can elevate your brand’s image. However, cost concerns should not deter you from utilizing them. By implementing these budget-friendly strategies, you can enjoy the benefits of rigid boxes without breaking the bank. Remember to balance your packaging requirements with your budget constraints to achieve both cost-effectiveness and brand impact. With the right approach, you can strike a perfect balance between quality and affordability in your packaging solutions. If you are interested in rigid boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Rigid Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Folding cartons are one of the most versatile forms of retail packaging—and how you print on them can make the difference between a product that blends in and one that commands attention. Strategic printing isn’t just about aesthetics; it’s about communicating value, increasing shelf appeal, and making your packaging work harder without adding cost. Here’s how to use print effectively to elevate your folding cartons—whether you’re working with skincare, supplements, food, electronics, or lifestyle products. Use Print to Create Visual Hierarchy Your folding carton only has a few seconds to make an impression on the shelf. Strategic printing helps guide the customer’s eye to what matters most. Tips: Use bold, contrasting colors or finishes (spot UV, foil) to highlight your brand name or logo Place key selling points (benefits, claims, features) front and center using larger font sizes Use typography and spacing to separate messaging and improve readability ✅ Helps the customer immediately understand what your product is and why it matters ✅ Improves visual impact without changing the structure ✅ Reduces reliance on costly redesigns by making the most of layout Match Print Quality to Product Value Your packaging should reflect the value of the product inside. Low-quality print on a premium item creates confusion—or worse, distrust. Use printing to reinforce brand perception. Recommendations: For high-end products, use offset or digital printing with high-resolution artwork Consider soft-touch coating, foil stamping, or embossed logos to enhance tactile appeal For entry-level products, clean flexo printing with sharp colors and simple messaging works well ✅ Aligns packaging with price point ✅ Builds customer trust and perceived quality ✅ Supports brand consistency across SKUs Make the Most of Every Panel Most folding cartons have six printable panels—front, back, two sides, top, and bottom. Don’t waste the real estate. Strategies: Use side panels for storytelling: sustainability efforts, brand values, QR codes Use bottom or inner flaps for certifications or required disclosures Add interactive elements (e.g., scan-to-learn codes) to drive post-purchase engagement ✅ Adds value without extra packaging ✅ Keeps primary panels clean and uncluttered ✅ Improves consumer education and brand connection Use Print to Simplify SKU Management For brands managing multiple SKUs or flavor/variant lines, digital printing or smart layout choices can reduce production complexity. Tactics: Create a shared dieline with only small design changes per SKU (e.g., color blocks, product names) Use black plate changes to keep core branding consistent while personalizing each version Leverage short-run digital printing for seasonal or promotional packaging ✅ Reduces setup and plate costs ✅ Increases flexibility for new launches ✅ Speeds up time to market for new variants Print for Retail Compliance Many retailers—especially in food, supplement, and cosmetic categories—have strict requirements around what’s displayed and where. Best practices: Print barcodes and expiration dates in scannable, clearly defined areas Use appropriate font sizes and spacing for ingredients, warnings, or supplement facts Leave space for lot coding or labeling if filled after printing ✅ Helps avoid costly chargebacks or relabeling ✅ Ensures legal compliance and customer clarity ✅ Streamlines vendor approvals Create a Memorable Unboxing Moment Folding cartons aren’t just for shelves—they also deliver an unboxing experience. The inside of the carton is an underutilized branding space. Ideas: Print a thank-you message or tagline inside the top flap Include hidden branding, illustrations, or QR codes inside the box Use the interior to reinforce key product benefits or cross-sell other products ✅ Turns packaging into a brand moment ✅ Encourages sharing and customer loyalty ✅ Adds value without structural changes Keep Production Methods in Mind Not every finish or design choice works with every printing method. Knowing the strengths of each helps you make the most cost-effective decision: Digital printing is perfect for small batches, personalized runs, or multiple SKUs Offset printing is ideal for high-quality retail packaging in larger volumes Flexographic printing is budget-friendly for basic folding cartons or larger quantities with simpler designs ✅ Ensures print decisions align with volume, speed, and budget ✅ Reduces production delays and unexpected costs Final Thoughts Your folding carton is more than just a box—it’s your on-shelf sales rep, brand ambassador, and customer touchpoint all in one. Strategic use of print can transform ordinary packaging into a powerful marketing tool, helping you communicate, connect, and convert. Need help making your folding carton print work harder? We’ll help you choose the right design, layout, and print method to bring out the best in your packaging—without overcomplicating your process or budget. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Folding Carton Facebook Twitter LinkedIn Pinterest Relevant Posts