Home » Packaging in 2026: Strategic Shifts Every Buyer Should Plan For

Packaging in 2026: Strategic Shifts Every Buyer Should Plan For

Evolving Demands, Smarter Decisions

As 2026 approaches, packaging decision-makers across sectors—from retail and ecommerce to industrial and medical—face a landscape shaped less by buzzwords and more by operational necessity. What’s ahead is not just about “going green” or “embracing automation,” but how these shifts are engineered into supply chains, cost structures, and compliance frameworks. Here’s what to actually expect—and plan for—if packaging is part of your bottom line.

Operational Sustainability Becomes Performance-Driven

Sustainability in 2026 will be measured less by marketing claims and more by performance thresholds. Expect rising demand for materials that balance recyclability, durability, and cost efficiency. Fiber-based packaging will continue to gain traction, but companies will increasingly analyze corrugated flute profiles, GSM ratings, and pallet optimization metrics to determine environmental impact through a logistics lens.

For example:

- Retailers may transition to thinner B-flute or E-flute boards for secondary packaging to reduce shipping weight.

- Industrial buyers will seek modular box sizes that minimize void fill while maximizing trailer cube efficiency.

- Medical and electronics sectors will emphasize FSC-certified materials with traceable sourcing and validated barrier protection.

Packaging that meets ISO 14001, APASS, and regional Extended Producer Responsibility (EPR) laws will be baseline expectations—not differentiators.

Customization Is No Longer Optional—It’s Configured

In 2026, off-the-shelf box sizing will no longer support the demands of fragmented product catalogs or diverse fulfillment strategies. Whether shipping a smart home device or a 60-lb appliance, businesses will rely on advanced structural design to reduce damages, dimensional weight costs, and consumer frustration.

Expect growth in:

- Auto-boxing and just-in-time kitting for multi-SKU orders.

- ESD-safe modular inserts for high-value electronics.

- Seasonal display-ready solutions engineered for co-packing and fast retail deployment.

Digital configurators will expand, allowing buyers to spec packaging with CAD-driven performance simulations, real-time quote modeling, and integrated sustainability scoring.

Technical Considerations for Holiday Fulfillment Packaging

To optimize fulfillment packaging during peak season, businesses should evaluate technical performance across multiple areas:

- Packout efficiency: Design kits and displays with fulfillment-friendly construction (e.g., quick-fold cartons, drop-in inserts, common dimensions)

- Structural compatibility: Ensure inner packs, cartons, and trays can be packed quickly and securely without secondary rework

- Barcode and label clarity: Use pre-applied or inline printed labels for traceability, GTIN compliance, and retailer scan accuracy

- Shipping durability: Account for stacking, vibration, and mixed-freight environments to avoid rework due to damage in transit

- Vendor-managed inventory (VMI) compatibility: If operating under VMI or JIT models, ensure real-time fulfillment visibility and flexibility

The more technical precision built into the packaging, the less risk of costly repackaging, returns, or retail chargebacks during peak execution.

Data-Backed Packaging Becomes the Standard

Buyers will increasingly demand quantitative justification for packaging decisions. Compression strength, burst resistance, drop-test validation, and real-time shipping analytics will factor into every spec sheet.

Companies will adopt packaging testing as a service, verifying that every structural design supports:

- Carrier-specific handling environments (e.g., FedEx vs. LTL freight).

- Product-level fragility indexes.

- Repetitive fulfillment automation requirements.

In short, packaging in 2026 must prove itself in real-world supply chains—not just lab conditions.

Labeling, Serialization, and Compliance Tighten

Whether it’s Amazon SIOC requirements, GS1 labeling standards, or sector-specific tracking protocols (like in pharma or aerospace), compliance will grow more complex. Expect increased interest in:

- Pre-printed compliance panels.

- Machine-readable codes for fulfillment automation.

- Tamper-evident and traceability elements integrated into box design.

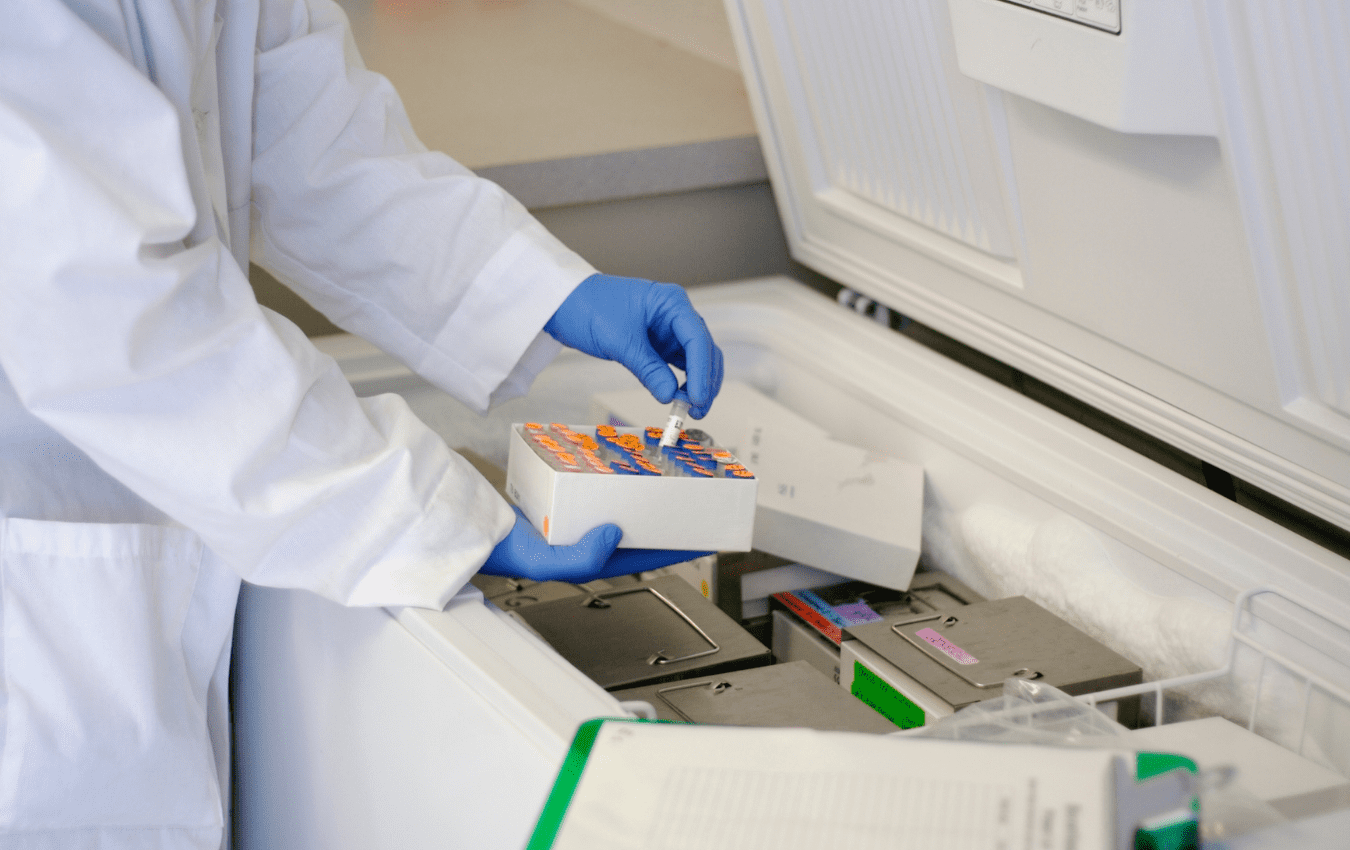

In industries like medical and food, validation processes will link packaging directly with inventory traceability systems and chain-of-custody requirements

Cold Chain, Humidity Resistance, and Long-Term Transit

Long-haul, climate-sensitive shipping is no longer niche. Expect new packaging RFPs in 2026 to prioritize:

- Moisture-resistant corrugated grades.

- Thermal liners and phase change materials in ecommerce-ready kits.

- Double-walled or triple-walled protection for oversized or high-value industrial goods.

For global fulfillment, buyers will need packaging that holds integrity over weeks in warehouse or transit environments that fluctuate in humidity, temperature, and stacking pressure.

Looking Ahead

Packaging in 2026 is less about trend-watching and more about aligning technical performance with real-world usage. Whether your business operates in ecommerce, electronics, furniture, or life sciences, the coming year will reward those who prioritize fit-for-purpose packaging that is backed by testing, scalable across channels, and cost-optimized without sacrificing protection or compliance.

Need packaging that’s built for how your business actually operates? Brown Packaging delivers engineered solutions that balance protection, cost efficiency, branding, and sustainability—backed by real testing and practical expertise.

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Home » Packaging in 2026: Strategic Shifts Every Buyer Should Plan For

The retail landscape is in a constant state of evolution, shaped by dynamic consumer behaviors and emerging trends. As consumer preferences continue to shift, retailers are tasked with the challenge of staying relevant and engaging. This blog delves into the critical role of adapting point-of-purchase (POP) displays and pack-out processes to meet changing consumer behavior. By embracing this evolution, retailers can create impactful shopping experiences, drive sales, and forge stronger connections with their audience. The Changing Face of Consumer Behavior Consumer behavior is not static; it’s a fluid phenomenon influenced by various factors like technology, socio-economic shifts, and cultural changes. In the digital age, consumers are more informed and discerning than ever before. They demand convenience, personalization, and authentic interactions with brands. Retailers must closely observe these shifts to design strategies that resonate with modern shoppers. Personalization as a Key Driver Gone are the days of generic displays and packaging. The rise of e-commerce and data-driven insights has ushered in the era of personalization. Retailers are leveraging consumer data to craft tailored shopping experiences. Personalized POP displays, backed by analytics, present consumers with products that align with their preferences and browsing history. This customized approach not only captures attention but also drives conversion rates. Elevating In-Store Experiences Physical retail spaces remain essential, albeit with a twist. Consumers now seek memorable in-store experiences that go beyond transactional interactions. Retailers are turning to experiential POP displays that engage the senses, educate, and entertain shoppers. From interactive product demonstrations to immersive storytelling, these displays create lasting impressions and transform shopping into an event. Seamless Online-Offline Integration The lines between online and offline shopping are blurring. Consumers often research products online before making in-store purchases, or vice versa. Retailers that seamlessly integrate their online presence with physical displays create a unified brand experience. QR codes, augmented reality, and digital touchpoints bridge the gap, enabling consumers to access additional product information and reviews on their smartphones while in-store. Pack-out Optimization for Modern Demands Pack-out, the process of organizing and shipping products, is undergoing a transformation to meet the demands of today’s consumers. Fast shipping, sustainability, and minimal waste are now paramount. Retailers are adopting eco-friendly packaging materials, optimizing box sizes for efficiency, and ensuring products arrive intact and in pristine condition. This not only reduces environmental impact but also enhances customer satisfaction. Responsive to Seasonal and Trend Changes Retailers must remain agile to adapt POP displays and pack-out processes to seasonal trends and emerging consumer preferences. With data analytics, retailers can identify patterns and anticipate shifts in demand. This foresight enables timely adjustments to display layouts, product assortments, and packaging, ensuring that consumers find what they need when they need it. Innovation and Technology Integration Innovative technologies are reshaping retail, and POP displays are no exception. Retailers are exploring digital signage, touchscreens, and interactive displays to engage shoppers and provide real-time product information. This integration of technology enhances the shopping journey, fosters brand loyalty, and offers a competitive edge in an ever-evolving market. Real-world Case Studies Across industries, retailers are embracing the evolution of consumer behavior by adapting their POP displays and pack-out strategies. From a beauty brand that used AR-powered displays to allow customers to virtually try on makeup products to a tech retailer that optimized its pack-out process for quick deliveries, real-world case studies highlight the tangible impact of staying attuned to consumer shifts. Embracing Retail Evolution In an era defined by change, the evolution of retail is an ongoing process. Adapting POP displays and pack-out processes to changing consumer behavior is not just a strategy—it’s a necessity. Companies that embrace this evolution are poised to create engaging experiences that resonate with modern shoppers, build brand loyalty, and thrive in an increasingly competitive landscape. By understanding consumer behavior, harnessing data, and infusing creativity, brands can navigate the ever-changing retail world with confidence and success. If you are interested pack-out and fulfilment in retail and pop display applications, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

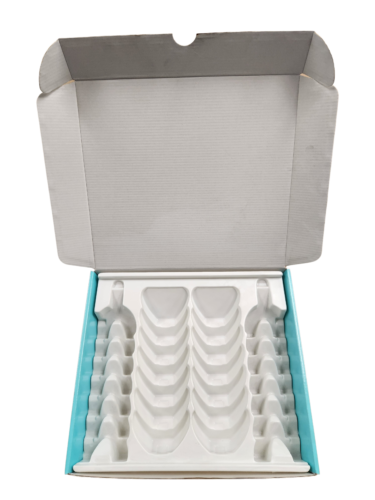

Custom box inserts are used to ensure your products are secure inside your box throughout the supply chain. They are used to keep your product safe as well as organized, especially if you have many products in one box. Having packaging inserts will give an impressive presentation. When a customer opens a box and sees the products organized in an insert, they will overall have a better impression of your brand. Regular packaging inserts are used more for retail applications as they showcase the product, while partition inserts are usually used for shipping products. Regular inserts hold a product in place, usually just at the bottom of the product while still showcasing the product itself. As for partitions, they cover almost the whole product to ensure it stays protected. Although it is not as eye catching as regular inserts, it is necessary depending on the product you are packaging. Partition inserts are best for bottles and glass due to its protective qualities. Different Types of Packaging Inserts: Packaging inserts vary by material, which provides them with certain properties, which can make them ideal for certain packaging applications. By understanding the difference between these types of packaging inserts, you can make more informed decisions on how to package, display and protect your product: Chipboard Corrugated Molded Pulp Foam Thermoform Chipboard Corrugated Foam Thermoform What are Chipboard Inserts? Chipboard or commonly known as paperboard is made from an interlaced network of cellulose fibers and is best used for holding small and lightweight products. It is the thinner of custom box inserts, and is the cheapest option. It will not offer the best protection compared to other inserts, but depending on what your product is, it could be the perfect fit. These inserts are best for items such as cosmetics, office supplies, food, and other light weight products. Color and Design: Standard white Natural Kraft Customizable with color and design Packaging insert or partition What are Corrugated Inserts? Corrugated comes in a wide range of strengths, size, and support. It is made with two outside paper layers and an inner flute layer, creating a sandwiched design. Based on the needed support more layers can be added to corrugated material to help improve its strength. These inserts are cost effective and eco-friendly. This material is best to hold medium weight products that need protection or have a lot of items in one box. Color and Design: Standard white Natural Kraft Customizable with color and design Packaging insert or partition What are Molded Pulp Inserts? Molded pulp is made up of a variety of materials like recycled paper and natural fiber that are formed in molds. Molded pulp can be manufactured in a few different ways, which are dry press, wet press, and processed. It is not usually printed on due to the surface texture, but it can have coatings added on top to create a more luxury appearance. This insert can have a high startup cost due to the price of the tooling and molding. It is molded to the product making it durable for packaging items like beverage and cosmetics. Materials used: Molded Pulp: Made from recycled paper and natural fibers Bagasse: Made from remains after crushing sugarcane and sorghum stalks What are Foam Inserts? Foam inserts are made from polymer matrix that combines heat, pressure, and gas bubbles to create solid foam. It is meant for holding the heaviest items and protecting the most fragile. These inserts are super lightweight and the most resistant to wear and tear. This insert can be created in many shapes, sizes, and designs. It offers maximum cushioning, lightweight ability, durable material, and it is perfectly fitted to products. Polyethylene Materials Used: Polyurethane (Ethers/Esters): Is superior in durability and is used in construction, medical, electronic devices, and industrial applications. Polyethylene: Comes in a variety of colors and density and used to protect electronic devices such as computers, auto parts and hard drives. Expanded Polystyrene: Offers high compression and thermal properties and is used for inner package support, box liners and pads What are Thermoform Inserts? Thermoform inserts are sturdy, rigid, and can hold a variety of items. They are a low weight option made from plastic materials. In order to make a thermoform insert, a mold must be created to fit your product and packaging. Then using heat and pressure the plastic is shaped to fit the mold. Although one of the sturdier inserts, it is also more costly. Like the molded pulp, thermoform has an expensive startup cost for tooling and molding. These inserts are best for electronic, industrial and medical applications. Materials Used: PET: Strong and light weight clear thermoplastic HDPE: Durable and strong with matte finish PVC: Flexible and heat resistant PP: High strength plastic with food safe capabilities and can be made with recycled material PS/HIPS: Best for heavy products PETG: Durable and high resistance to chemicals, heat, and water PC: Heat resistant, good electrical insulation properties Summary: Selecting the Right Packaging Inserts Inserts are important when it comes to packaging your products. They will keep your products safe and organized from production to the end point. It will give strong protection to ensure there is no breakage or issues. It also gives the ability to ship multiple products together ensuring each product stays in its respective location for unboxing. Overall investing in inserts will enhance the customers experience when receiving your product. There are many types of packaging inserts, finding the one that fits your business needs is important. If you need assistance in choosing which insert would be best for your business needs, please contact Brown Packaging today and one of our packaging specialists will assist you. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Inserts Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of logistics and e-commerce, shipping is a critical aspect of business operations. Among the various packaging options, the Regular Slotted Container (RSC) box stands out as a versatile choice for shipping a wide range of products. To ensure your shipping endeavors with RSC boxes are both effective and efficient, it’s crucial to follow best practices and strategies. In this article, we’ll explore the key approaches to successfully ship RSC boxes. Choose the Right RSC Box Size Selecting the appropriate box size is essential when using RSC boxes for shipping. Oversized boxes waste space and may lead to higher shipping costs, while undersized boxes risk damaging your products. Therefore, it’s vital to measure your items carefully and opt for an RSC box that provides a snug fit with minimal extra space. Quality Matters Invest in high-quality RSC boxes. Boxes made from sturdy corrugated cardboard with durable seams and proper adhesive are crucial for protecting your products during transit. Quality boxes ensure that your goods reach their destination in optimal condition, without suffering damage due to external forces such as crushing or impacts. Proper Packing Material In addition to selecting the right RSC box, choosing the appropriate packing materials is equally important. Use cushioning materials like bubble wrap, packing peanuts, corrugated or foam inserts to safeguard your products from shocks and vibrations during shipping. Ensure there’s an adequate buffer between the product and the inner walls of the box. Seal Boxes Securely Properly sealing your RSC boxes is vital to prevent any unintended openings during shipping. Use high-quality packing tape to securely seal both the top and bottom flaps of the box. Ensure that the seams are tightly sealed, with no gaps or openings that could compromise the integrity of the box. Labeling and Documentation Clearly label each RSC box with essential information, including the recipient’s address, your return address, and any special handling instructions. Employ high-quality labels that won’t smudge or peel during transit. Additionally, don’t forget to include any required shipping documentation, such as packing slips, invoices, or customs forms, especially when shipping internationally. Weight Distribution Evenly distribute the weight of your products within the RSC box. Avoid placing heavy items on top of delicate ones. Utilize dividers or partitions if necessary to prevent items from shifting during transit. This practice helps maintain the structural integrity of the box and ensures that the products remain secure. Consider Environmental Impact Incorporate eco-friendly practices into your shipping process. Opt for recyclable and biodegradable packing materials whenever possible. Additionally, choose RSC boxes made from sustainable or recycled materials to reduce your environmental footprint. Shipping Carrier Selection Select a reputable shipping carrier that aligns with your business needs. Factors to consider include shipping speed, cost, reliability, and coverage. Negotiating shipping rates and exploring bulk shipping options can help reduce shipping costs. Track Shipments Utilize tracking services provided by shipping carriers. This enables you to monitor the progress of your shipments, provide customers with accurate delivery estimates, and promptly address any issues that may arise during transit. If you are interested in RSC Boxes, custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom RSC Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts