Home » Benefits of Edge Protectors for Pallet Shipping

Benefits of Edge Protectors for Pallet Shipping

In shipping large quantities of goods, ensuring the safety and stability of pallet loads is paramount. Edge protectors play a vital role in protecting palletized shipments from damage during transportation and handling. This blog explores how edge protectors enhance the security of pallet loads, their types, and the benefits they bring to logistics and supply chains.

What Are Edge Protectors?

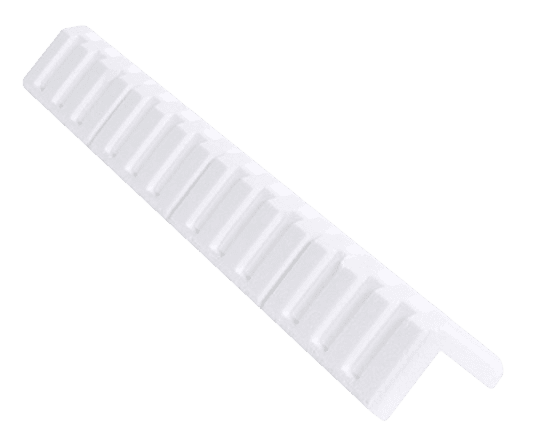

Edge protectors, also known as corner protectors, are sturdy materials placed along the edges of palletized loads to provide reinforcement and protection. Typically made from plastic, corrugated, or foam materials, edge protectors prevent damage to packaging and products during strapping, stacking, and transit. They come in various sizes, thicknesses, and shapes, such as L-shaped or flat, to suit different load configurations.

Types of Edge Protectors

Plastic Edge Protectors

- Material: High-density polyethylene (HDPE).

- Uses: Ideal for securing heavy pallet loads.

- Benefits: Strong and durable, resistant to moisture and impact, and reusable.

Corrugated Edge Protectors

- Material: Sturdy corrugated board.

- Uses: Suitable for eco-conscious businesses or lighter palletized goods.

- Benefits: Lightweight, recyclable, and customizable in length and thickness.

Foam Edge Protectors

- Material: Shock-absorbing foam.

- Uses: Best for fragile or sensitive products on pallets.

- Benefits: Provides superior cushioning against impacts and vibrations during transport.

Benefits of Edge Protectors for Pallet Loads

- Enhanced Stability

Edge protectors help secure straps tightly around palletized loads, reducing the risk of movement or shifting during transportation. This stability minimizes the likelihood of toppled pallets and damaged products.

- Prevents Strap Damage

Tensioned straps can dig into packaging, causing tears or deformation. Edge protectors distribute the pressure evenly across the load, safeguarding both the packaging and the products inside.

- Improved Load Integrity

By reinforcing the corners and edges of a pallet load, edge protectors prevent crushing and damage, particularly for cartons stacked at the bottom of the pallet.

- Reduced Shipping Costs

Minimizing damage to goods lowers the risk of returns and replacements, reducing overall shipping expenses and improving profit margins.

- Streamlined Stacking and Storage

Edge protectors maintain the structural integrity of stacked pallets, allowing for safe and efficient storage in warehouses or during transit.

- Enhanced Sustainability

Corrugated edge protectors are biodegradable and recyclable, making them an eco-friendly choice for businesses aiming to reduce their environmental impact.

- Protection Against Legal Liability

Properly secured pallet loads with edge protectors demonstrate due diligence in product safety, reducing the risk of legal disputes over damaged goods during transportation.

Customization for Pallet Loads

Edge protectors can be customized to fit the unique requirements of palletized shipments:

- Length and Thickness: Tailor edge protectors to match pallet dimensions and load weight.

- Materials: Choose foam for fragile products or plastic for heavier loads.

- Branding: Add logos or company branding for enhanced visibility and professional presentation.

Conclusion

Edge protectors are indispensable for protecting palletized goods during shipping, ensuring stability, reducing damage, and lowering costs. They provide a cost-effective solution to safeguard products, maintain load integrity, and enhance overall operational efficiency.

Interested in stock or custom edge protectors for palletized loads? Contact Brown Packaging today to explore options tailored to your business needs.

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Home » Benefits of Edge Protectors for Pallet Shipping

Temperature fluctuations can have a detrimental effect on your products and packaging. Whether your goods are sensitive to extreme heat or cold, maintaining the right temperature during storage and transportation is essential. In this blog, we’ll explore various strategies and best practices to help you protect your packaging against temperature fluctuations effectively. Understanding the Risks Before we delve into protective measures, it’s crucial to understand the potential risks associated with temperature fluctuations: Product Quality: Fluctuating temperatures can alter the quality, texture, and taste of products, rendering them unsellable or unsafe for consumption. Chemical Reactions: Some products, particularly chemicals and pharmaceuticals, can undergo chemical reactions when exposed to temperature extremes, resulting in changes in composition or efficacy. Packaging Integrity: Extreme temperatures can weaken packaging materials, making them more susceptible to tears, punctures, or structural damage. Protective Measures To safeguard your packaging against temperature fluctuations, consider implementing the following protective measures: Temperature-Controlled Packaging: Use temperature-controlled packaging solutions, such as insulated boxes, coolers, or heated containers, depending on the specific temperature requirements of your products. Insulated Packaging Materials: Choose packaging materials with insulating properties. Foam, bubble wrap, or insulated liners can help maintain stable temperatures within the package. Phase-Change Materials: Incorporate phase-change materials or gel packs into your packaging. These materials can absorb or release heat to help regulate the temperature inside the package. Seal Integrity: Ensure that packaging seals are strong and airtight. Regular quality control checks should verify that no gaps or defects exist in the sealing process to prevent temperature infiltration. Packaging Design Considerations: Design packaging with temperature resistance in mind. Use materials that can withstand temperature extremes, and consider multi-layer structures for added insulation. Quality Testing: Conduct rigorous testing to verify the effectiveness of your packaging in maintaining temperature stability. Use temperature testing chambers to simulate real-world conditions. Temperature Monitoring Devices: Incorporate temperature monitoring devices, such as data loggers or indicators, into your packaging. These devices record temperature data during transit, providing insight into temperature fluctuations. Controlled Storage Facilities: Store products in temperature-controlled environments before and after packaging. Warehouses and storage areas should be equipped with adequate ventilation, heating, and cooling systems. Shipping Route Planning: Select shipping routes and carriers that prioritize temperature control and offer refrigerated or climate-controlled transportation options. Regulatory Compliance: Adhere to industry-specific and regulatory standards for temperature-sensitive products. Compliance ensures that your products meet safety and quality requirements. Vigilance and Continuous Improvement Protecting your packaging against temperature fluctuations is an ongoing effort. Continuously assess your packaging solutions and gather feedback from transportation partners to identify any weaknesses or areas for improvement. Make necessary adjustments to enhance temperature resilience and ensure that your products arrive at their destination in optimal condition. By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of temperature-related damage to your products, enhance their overall quality and safety, and meet the specific temperature requirements of your industry. If you are interested in protection against temperature fluctuations for your packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Cold Chain Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the current competitive retail landscape, the packaging of a product plays an increasingly significant role in customer decision-making. Brands are progressively realizing the power of packaging as a communication tool. Among the many forms of packaging available, blister packs stand out as a popular choice for several reasons. They strike a balance between product visibility, protection, and cost-effectiveness, hence the growing demand across various industries. Defining Blister Packs: A Quick Overview Blister packs, also mistaken as clamshell packaging, are pre-formed plastic packaging solutions that seal the product against a cardboard backing or another plastic component. This type of packaging is widely used for small consumer goods, pharmaceuticals, and medical devices. Their design is purposefully transparent to showcase the product within, offering potential buyers a clear view of what they’re about to purchase. Increased Product Visibility: The Window to Purchase Decision Showcasing Product Quality One of the most significant advantages of blister packs is the transparency that allows customers to view the product directly. With the rise of informed consumers, the ‘see before you buy’ concept has never been more crucial. By providing an unobstructed view, blister packs instill confidence in the product, as consumers can verify the product’s condition and quality firsthand. Highlighting Product Features Through a blister pack’s clear plastic cover, brands have the opportunity to highlight the most critical product features. This visual promotion can be a game-changer, particularly for products with unique design elements or accessories that the company wants to emphasize. Deterring Product Tampering Product visibility also plays a vital role in preventing tampering. With blister packs, any signs of interference are easily recognizable, thus providing an additional layer of assurance to customers about the product’s integrity. Superior Product Protection: Ensuring Safety and Longevity Resistance to External Factors Blister packs provide superior protection against numerous external factors such as moisture, light, and temperature changes, making them suitable for products sensitive to such conditions, like pharmaceuticals and electronics. Enhancing Product Life Blister packs are designed to be tough and durable. The rigid plastic housing protects the product from mechanical damage during transport or in-store handling, thereby extending the product’s shelf life and ensuring it reaches the consumer in its best state. Improved Tamper Evident Packaging As previously mentioned, blister packs deter tampering. However, they also serve as excellent tamper-evident packaging. If the package is opened or damaged, it is immediately noticeable, allowing both the seller and the buyer to be assured of the product’s untouched condition. Balancing Cost-effectiveness and Environmental Concerns While the benefits of product visibility and protection are undeniable, it’s essential to highlight that blister packs are also cost-effective and can be designed with environmental concerns in mind. Economical Production and Versatility The production process for blister packs is relatively economical, making them an affordable option for many businesses. The versatility of blister packaging, fitting a wide range of products, also contributes to its cost-effectiveness. Eco-friendly Options In addition to traditional blister packs, some companies are now offering eco-friendly alternatives known as “trap packs.” Trap packs are designed with sustainability in mind, using recycled materials or materials that are easier to recycle. PET (Polyethylene Terephthalate) and RPET (Recycled Polyethylene Terephthalate) are commonly used due to their high recyclability. These eco-conscious trap packs provide the same level of visibility and protection while minimizing their environmental impact. Conclusion: The All-Round Packaging Solution Blister packs have proven their value in the world of product packaging. By boosting visibility and offering superior protection, these packs are instrumental in driving purchase decisions while ensuring products reach consumers in optimal condition. As eco-friendly options like trap packs become more widely available, blister packs are positioned to remain a popular choice for packaging needs in the foreseeable future. If you are interested in blister packs, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Blister Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

When you ship items, you run the risk of damaging them during transit. Even with careful handling, packages can bump into each other and sustain damage. That’s why it’s crucial to take measures to protect your packages during shipping. One of the easiest and most effective ways to do this is by using corrugated edge protectors. Corrugated edge protectors add an extra layer of protection to the edges and corners of your packages, preventing them from getting damaged during shipping. In addition to using edge protectors, you can also choose to use stretch film to further secure your package and prevent damage. While stretch film is optional, it can be especially useful for packages with irregular shapes or multiple items. 7 Steps to Using Corrugated Edge Protectors In this guide, we’ll take you through the steps of using corrugated edge protectors, with the option of using stretch film, to protect your packages during shipping. Step 1: Determine the size of the edge protectors you need The first step in using corrugated edge protectors is to measure the item you’re shipping. Determine the length, width, and thickness of the packaging material you’ll be using. You’ll need to choose edge protectors that are slightly larger than the item to ensure adequate protection. Additionally, consider the weight and fragility of the item. Heavier items may require thicker edge protectors, while fragile items may need extra padding or cushioning. Step 2: Choose the right type of edge protector There are several types of edge protectors to choose from, including L-shaped, U-shaped, and C-shaped protectors. L-shaped protectors are best for protecting corners, while U-shaped protectors are designed to wrap around the edge of an item. C-shaped protectors are ideal for cylindrical items like pipes or tubes. You’ll also need to choose the right material for the edge protectors. Cardboard, plastic, and foam are common options. Each material has its own strengths and weaknesses, so choose the one that best suits your needs. Step 3: Cut the edge protectors to size Use a utility knife or box cutter to cut the edge protectors to the appropriate size. Cut them long enough to cover the entire edge or corner of the item, and wide enough to provide adequate protection. For L-shaped protectors, cut the corner at a 45-degree angle to ensure a snug fit. U-shaped protectors should be cut at a 90-degree angle. Step 4: Secure the edge protectors to the item Use tape or adhesive to secure the edge protectors to the cardboard or other packaging material. Apply the tape or adhesive to both the edge protector and the packaging material to ensure a secure hold. Make sure the edge protectors are properly aligned to provide adequate protection. Step 5: Add additional protection if needed For fragile items or those with irregular shapes, consider adding additional protection. Bubble wrap, packing peanuts, or other protective materials can help cushion the item and prevent damage during shipping. If you choose to use stretch film, wrap it tightly around the package, ensuring that it’s snug but not so tight that it damages the package or its contents. Choose the appropriate type of stretch film for your specific needs, as different types have varying levels of strength and stretchability. Step 6: Label and ship the package Label your package with any necessary shipping information, such as the destination address and tracking number. Add a “Fragile” or “Handle with Care” label if necessary. Use a permanent marker or label maker to create clear, legible labels and place them in a visible location on the package. Step 7: Monitor the shipment Keep track of the shipment by utilizing the tracking information provided by the carrier. Regularly check the status and location of your package to ensure its progressing smoothly towards its destination. If you encounter any delays or issues during the shipment, promptly contact the carrier to address the problem. In cases of damaged or lost items, you may need to file a claim with the carrier to seek compensation or resolution. Summary: Edge Protectors By following these steps, you can effectively protect your packages during shipping using corrugated edge protectors and optional stretch film. Start by measuring your item and selecting the appropriate size and type of edge protectors. Cut them to size and securely attach them to your package. If necessary, add extra protection such as bubble wrap. Optionally, wrap the package with stretch film for added security, particularly for irregularly shaped or multiple-item packages. Properly label the package and monitor the shipment using tracking information. Remember, taking the time to properly protect your packages will help minimize the risk of damage during shipping. Whether you’re sending fragile items or packages with irregular shapes, using corrugated edge protectors and optional stretch film will provide an extra layer of protection and peace of mind. Happy shipping! If you are interested in edge protectors or corner boards, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Edge Protectors Facebook Twitter LinkedIn Pinterest Relevant Posts