Home » Bringing Your Small Business Product to Retail

Bringing Your Small Business Product to Retail

As a small business owner, bringing your product to retail is a significant milestone, and the packaging plays a crucial role in making a lasting impression on customers. Proper packaging not only protects your product but also enhances its visual appeal and brand recognition. In this comprehensive guide, we’ll walk you through the essential steps and considerations for creating the correct and proper packaging for your product as you navigate the retail landscape.

Understand Your Product and Audience

Before diving into packaging design, take the time to thoroughly understand your product and target audience. What are the unique features and benefits of your product? What problem does it solve for your customers? Knowing your product inside and out will help you tailor your packaging to its specific needs and the preferences of your audience.

Determine Your Budget

Packaging costs can vary significantly depending on factors like materials, design complexity, and order quantity. Determine your budget for packaging early in the process to ensure you strike the right balance between cost and quality. Remember that packaging is an investment in your brand’s success.

Choose the Right Materials

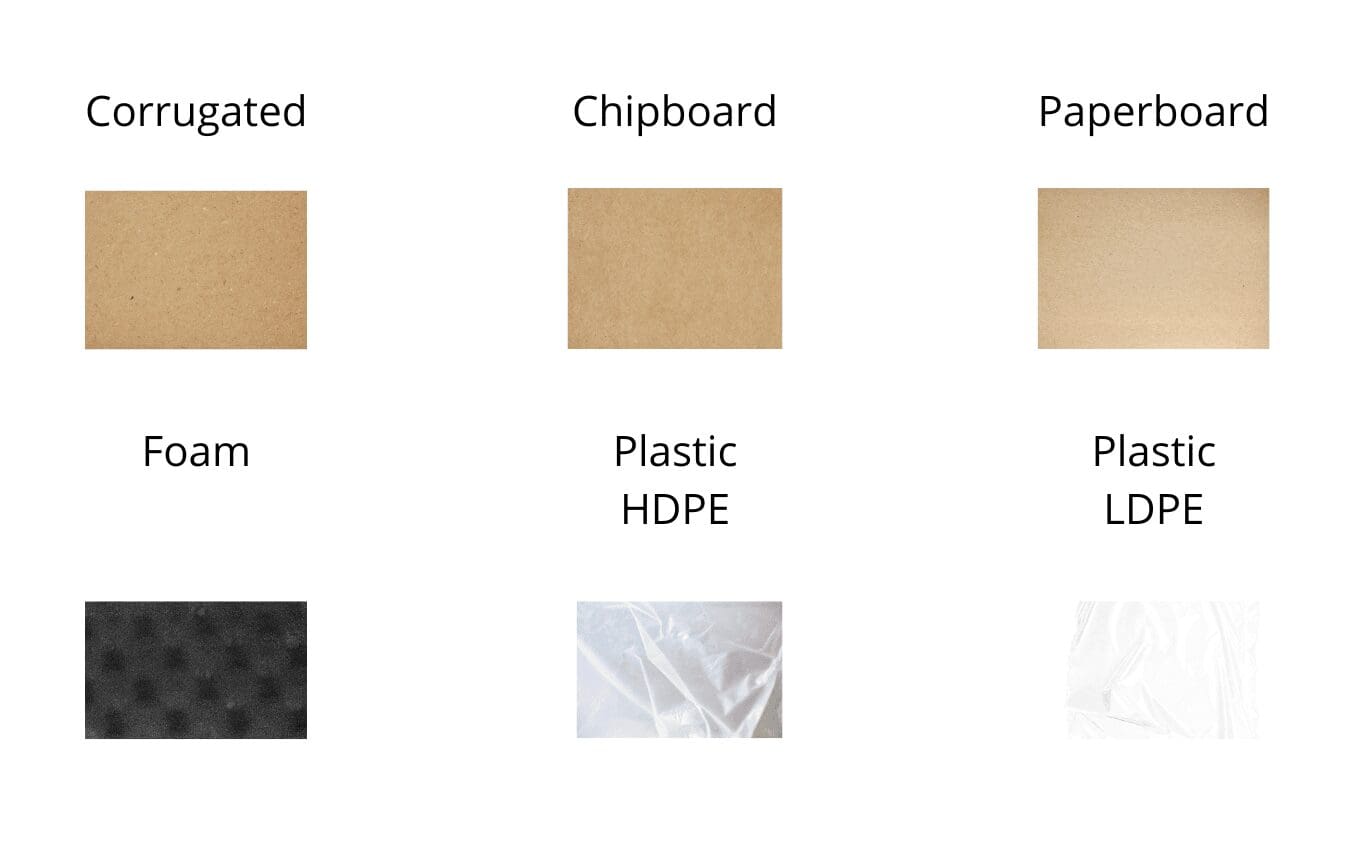

Selecting the appropriate packaging materials is essential for product protection and presentation. Consider factors such as product fragility, weight, and environmental impact when choosing materials. Common packaging materials include cardboard, corrugated cardboard, plastic, glass, and more. If sustainability is a priority, explore eco-friendly options.

Focus on Functionality

Functionality is key when designing retail packaging. Your packaging should not only protect your product but also make it easy for customers to access and use. Consider features like resealable closures, easy-open tabs, and clear windows that allow customers to see the product inside.

Design for Brand Identity

Your packaging should align with your brand’s identity and convey a cohesive message. Use your brand colors, logo, and typography consistently across all packaging elements. A well-designed package enhances brand recognition and encourages customer loyalty.

Follow Retailer Guidelines

If you plan to sell your product through specific retailers, be sure to understand their packaging guidelines and requirements. Retailers often have specific packaging standards that must be met for shelf placement. Failing to comply with these guidelines can hinder your product’s entry into retail stores.

Test and Iterate

Before finalizing your packaging, conduct testing and gather feedback. Test the packaging for durability, functionality, and visual appeal. Seek input from potential customers, friends, or focus groups to ensure it resonates with your target audience. Be open to making adjustments based on the feedback you receive.

Consider Sustainability

Sustainability is an increasingly important factor in packaging design. Many consumers prefer eco-friendly packaging, so explore options like recyclable materials, reduced packaging waste, and sustainable printing practices. Highlight your commitment to sustainability on your packaging if applicable.

Work with Professionals

If you’re not confident in your packaging design skills, consider working with packaging professionals, such as graphic designers and packaging manufacturers. They can provide expertise and guidance to create packaging that meets industry standards and customer expectations.

Plan for Production and Distribution

Once you’ve finalized your packaging design, plan for production and distribution. Choose a reliable packaging manufacturer or supplier that can meet your production needs. Ensure that your packaging is compatible with your distribution methods and can withstand the rigors of shipping and handling.

Conclusion

Creating the correct and proper packaging for your small business product is a critical step in bringing it to retail success. Invest time and resources in thoughtful packaging design that aligns with your brand identity, appeals to your target audience, and meets retailer requirements. A well-designed package not only enhances your product’s chances of success on retail shelves but also communicates your brand’s values and quality to customers. With the right packaging strategy, your small business can make a memorable impact in the retail marketplace.

If you are interested in bringing your products to retail with the correct packaging solutions, then partner with Brown Packaging today to get started.

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the

Home » Bringing Your Small Business Product to Retail

Point-of-purchase (POP) displays are designed to capture shopper attention and influence buying decisions. Beyond structure and branding, the quality of print determines how well a display communicates from multiple viewing angles in a retail environment. Selecting the right printing method ensures your display performs both visually and functionally. Printing Methods for Corrugated POP Displays Not all printing methods are suited for corrugated displays. Each has its own strengths and trade-offs in cost, speed, quality, and run size. The three most common methods are: Flexographic Printing Digital Printing Lithographic (Offset) Printing Flexographic Printing Flexographic printing uses plates to apply ink as material passes through rollers. Advantages Cost-Efficient at Scale: Once plates are created, cost per unit is low for large or repeat orders. Pantone Accurate: Ensures precise color matching across production runs. Versatile: Works on uneven surfaces and a wide range of substrates. High Speed: Suited for mass production. Limitations High Startup Costs: Plates and tooling are expensive, making short runs less economical. Poor for Sampling: Costly and impractical to produce prototypes. Best Fit: Large-volume retail displays where consistency and color accuracy are priorities. Digital Printing Digital printing applies artwork directly from a file to the substrate, eliminating plates. Advantages Low Startup Cost: Cost-effective for short runs and prototypes. Fast Turnaround: Ideal for tight deadlines or seasonal campaigns. Flexible: Easily handles multiple SKUs or frequent artwork changes. High Quality: Produces sharp graphics suitable for branded displays. Limitations Less Economical at Scale: Higher cost per unit for large volumes. Color Variability: Approx. 95% accurate; not a perfect Pantone match. Slower Mass Output: Not as efficient as flexographic presses for high quantities. Best Fit: Small-batch retail displays, prototypes, or variable-data campaigns. Lithographic (Offset) Printing Lithographic printing transfers ink from a plate to a rubber blanket, then onto the substrate, with options for coatings or varnishes. Advantages Highest Quality: Sharp, detailed graphics with accurate color reproduction. Premium Finishes: Coatings and varnishes enhance durability and appearance. Scalable: Handles small to large format prints. Limitations High Setup Cost: Plates and setup make short runs expensive. Not Sample-Friendly: Prototypes are cost-prohibitive. Longer Lead Time: Setup and adjustments require planning. Best Fit: High-volume displays where premium image quality is essential for brand impact.` Designing Graphics for POP Displays Effective POP displays combine structure with clear, impactful graphics. Common elements include: Logos and Brand Colors Product Imagery Text (ingredients, instructions, contact info) Symbols and Icons Promotions or Pricing Call-to-Action Messaging Mascots or Characters Any artwork provided must be adjusted to fit dielines correctly. Designers ensure bleed, folds, and structural features align with graphics to avoid misprints. Choosing the Right Printing Method When selecting a printing process, consider: Quality: Lithographic offers the highest resolution; flexographic is durable but less detailed. Budget and Quantity: Flexographic suits large runs, digital works best for small runs, lithographic for high-volume premium graphics. Lead Time: Digital is fastest due to no plate requirements. Brand Goals: For premium retail impact, lithographic justifies higher cost; for efficiency, flexographic is the workhorse. Buyer Takeaway Use flexographic printing for large-scale runs that need durability and consistent Pantone colors. Choose digital printing for prototypes, short runs, or campaigns with multiple SKUs. Invest in lithographic printing for premium displays that require sharp, high-quality graphics. Selecting the right method ensures POP displays not only stand out visually but also align with budget and timeline requirements. References Association of Independent Corrugated Converters (AICC). (2024). Printing Methods in Corrugated Packaging. Retrieved from https://www.aiccbox.org Flexible Packaging Association. (2023). Digital vs. Flexographic Printing. Retrieved from https://www.flexpack.org Robertson, G. L. (2016). Food Packaging: Principles and Practice (3rd ed.). CRC Press. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Folding Carton Display Packaging Rigid Box Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to maximizing shelf space and capturing buyer attention, few pairings are more effective than folding cartons and POP displays. Whether it’s a full-size floor display or a compact countertop display, using folding cartons within your display system brings structure, brand consistency, and a retail-ready finish that helps your product stand out—and sell. Here’s how and why folding cartons and POP displays work so well together—and how you can use both to your advantage in-store. What Each Does Best Understanding the strengths of each packaging component helps you combine them more effectively: Folding Cartons are primary packaging. They hold, protect, and present your product, while also delivering branding, compliance, and consumer communication. POP (Point-of-Purchase) Displays are secondary packaging built for retail presentation—designed to showcase multiple products in high-traffic areas like endcaps, aisles, and counters. Used together, they create a powerful presentation system that delivers both structure and shelf appeal. Folding Cartons Add Structure Inside the Display When placed inside a POP display, folding cartons help: Keep products organized and upright Prevent movement and scuffing inside the display Maintain a clean, uniform look throughout the lifespan of the promotion This is especially important for countertop displays, where customers may interact directly with the packaging—grabbing one item at a time. ✅ Prevents messy or slouched displays✅ Improves shopability and perceived value✅ Ensures product presentation stays consistent Cartons Enhance Branding Within the Display The display may carry your logo and key messages—but the folding carton is what customers will take home. That’s why it’s important to align the carton design with the display artwork. Tips: Match color palettes and typography between the carton and display Include consistent messaging across both components Ensure front panels of cartons are fully visible and legible within the display tray ✅ Reinforces brand identity✅ Creates a seamless shopper experience✅ Builds brand recall after purchase Essential for Club Stores, Retail Chains & Promotions Many retail and club store environments require retail-ready packaging that combines display and individual packaging. Folding cartons placed in POP displays are perfect for: Multi-pack promotional kits Trial-size or travel-size programs New product launches Seasonal or endcap promotions In club stores, countertop displays or tray packs with folding cartons make it easy for stores to place the product on display without repackaging—saving time and increasing compliance. ✅ Satisfies retail guidelines✅ Makes setup easier for staff✅ Streamlines logistics for brand and retailer Great for High-Volume, Low-Footprint Selling Countertop displays are used in checkout lanes, convenience stores, cafes, and specialty boutiques—anywhere space is tight and impulse purchases are common. Folding cartons in countertop displays are perfect for: Supplements or wellness shots Candy, snacks, or gum Small beauty items or trial kits Electronics accessories or travel essentials These cartons provide structure and protection while still being compact and lightweight—ideal for high-turnover items. ✅ Encourages grab-and-go sales✅ Protects product without adding bulk✅ Gives retailers a neat, self-contained unit Cartons Make Replenishment and Restocking Easy Retail staff love displays that are easy to restock. Folding cartons simplify the process: Easy to count, refill, or rotate Stackable within the display tray Protect the product even after multiple interactions You can even use numbered or color-coded cartons to help identify flavors, formulas, or SKUs within the same display. ✅ Reduces downtime at shelf✅ Keeps displays neat throughout their lifecycle✅ Makes multi-SKU management easier Final Thoughts Folding cartons and POP displays—especially countertop displays—go hand in hand when it comes to boosting product visibility, protection, and in-store performance. While the display grabs attention, the carton delivers branding, clarity, and trust. Need help designing folding cartons that work with POP displays?We’ll help you create a cohesive packaging system that blends structure, design, and in-store efficiency to drive retail success. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

POP displays must balance eye-catching branding with structural integrity. Inadequate load-bearing design can result in product sagging, leaning, or complete collapse, which not only risks product loss but also damages retailer confidence. By applying engineering principles, testing protocols, and correct material selection, brands can maximize display stability without unnecessary cost. Understanding Load-Bearing Capacity Static Load vs. Dynamic Load: Static load refers to the total weight a display can hold without movement. Dynamic load accounts for forces during handling, stocking, and customer interaction. Failure Modes: Panel buckling, shelf deflection, joint separation, and base collapse are the most common failure points. Material Selection Corrugated Board Strength: Flute profile (B, C, E, or BC) impacts stiffness and stacking strength. Higher ECT boards increase vertical load capacity but also affect cost and weight. Coatings and Laminates: Water-resistant coatings prevent fiber weakening in humid environments. Laminates can increase rigidity but may impact recyclability. Structural Reinforcements Double-Wall Shelving: For heavier products such as beverages or canned goods. Internal Braces: Die-cut supports hidden behind the graphic panels for increased stability. Base Skids: Distributes load more evenly to prevent floor contact wear and pallet jack damage. Design and Geometry Weight Distribution: Heavier SKUs should be placed at lower tiers to reduce tipping risk. Joint Engineering: Lock tabs, glue flaps, and interlocking slots improve structural stability. Shear Resistance: Cross-bracing and panel alignment reduce the risk of diagonal collapse. Testing Protocols ASTM D642: Measures compression strength to determine safe stacking loads. ISTA 3A & 6-Series: Simulates real-world handling, vibration, and impact. Shelf Deflection Tests: Measures how much a shelf bends under load over time. Best Practices Always design for at least 25% higher load capacity than the expected maximum product weight. Validate prototypes under realistic load and environmental conditions before production. Balance cost-to-performance ratio — over-engineering increases cost without visible retail benefit. References ASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://www.astm.org/d0642-15.htmlInternational Safe Transit Association. (2018). ISTA 3A general simulation performance test for packaged-products for parcel delivery system shipment. ISTA. https://ista.org/International Safe Transit Association. (2018). ISTA 6-Series transit tests. ISTA. https://ista.org/ (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts