Home » Strategies to Protect Packaging Against Physical Damage

Strategies to Protect Packaging Against Physical Damage

Packaging is the first line of defense for your products, shielding them from the hazards they may encounter during storage, handling, and transportation. One of the most critical aspects of packaging is safeguarding it against physical damage. In this blog, we’ll delve into various strategies and best practices to help you protect your packaging from physical harm, ensuring that your products remain safe and intact.

Understanding the Risks

Before delving into protective measures, it’s crucial to understand the potential sources of physical damage that your packaging might face:

- Impact during Handling: Packages can be dropped, bumped, or mishandled during various stages of transportation and storage.

- Compression: Stacking heavy items or applying excessive pressure can lead to package deformation or crushing.

- Vibration: Prolonged exposure to vibrations, especially in long-distance shipping, can weaken packaging materials and affect their integrity.

- Sharp Objects: Sharp objects in the vicinity of packages can puncture or tear the packaging material.

Protective Measures

To safeguard your packaging from physical damage, consider the following protective measures:

Material Selection:

Choosing the right packaging material is paramount. Select materials known for their durability, strength, and resistance to physical damage.

Reinforced Corners and Edges:

Weak points in packaging are often the corners and edges. Reinforce these vulnerable areas with additional layers of material or protective corner guards to absorb impact and prevent crushing.

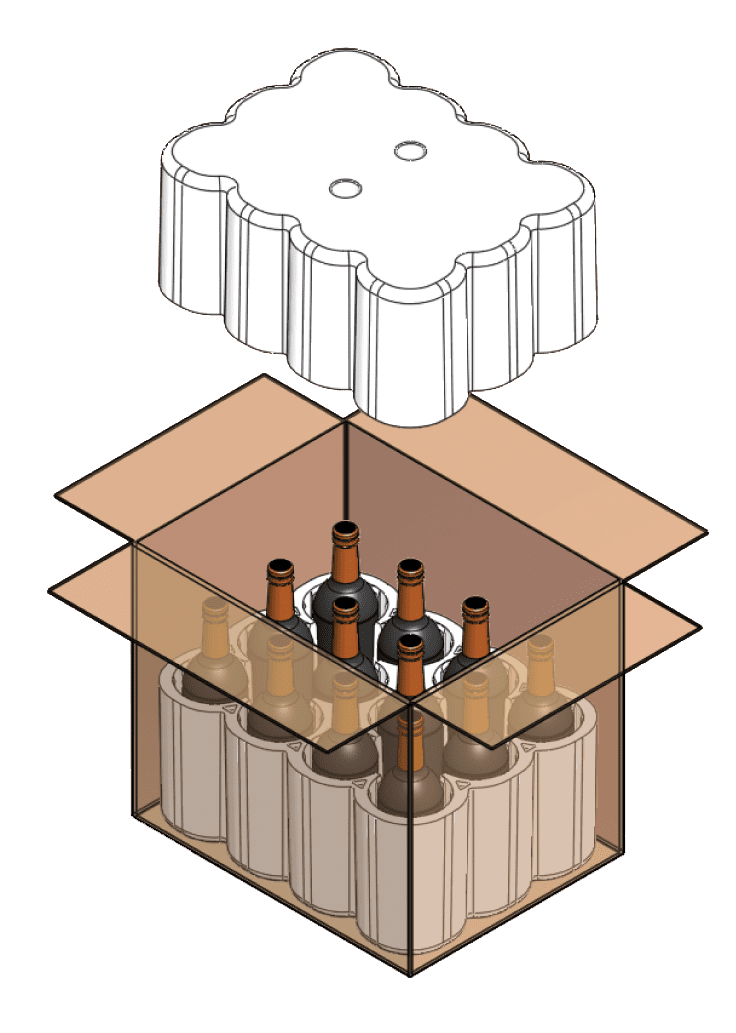

Cushioning and Padding:

Using cushioning materials like bubble wrap, foam inserts, or air pillows can provide a protective buffer against shocks and vibrations. Ensure that products are snugly cushioned inside the packaging.

Stacking Strength:

If stacking is a concern, design packaging with enhanced stacking strength. Reinforce the packaging structure to distribute weight evenly and minimize the risk of crushing.

Inner Packaging Layers:

For particularly fragile or sensitive items, consider adding inner packaging layers. These can include protective pouches, sleeves, or dividers to prevent product-to-product contact and potential damage.

Impact Indicators:

Use impact indicators or shock labels on packages. These devices can detect and record impacts during transportation, allowing you to identify and address any potential issues promptly.

Testing and Quality Control:

Implement rigorous testing procedures to ensure the packaging can withstand expected impacts and stresses. Conduct drop tests, compression tests, and vibration tests to assess package durability.

Customized Packaging Design:

Tailor packaging designs to fit the specific requirements of your products. Avoid using oversized boxes, as this can lead to excessive movement and damage.

Handling and Storage Guidelines:

Provide clear instructions for handling and stacking packages. Train employees and partners involved in the packaging and transportation process to follow these guidelines diligently.

Regular Evaluation and Improvement

The protection of your packaging from physical damage is an ongoing process. Continuously assess your packaging solutions and gather feedback from transportation partners to identify any weaknesses or areas for improvement. Make necessary adjustments to enhance packaging resilience and ensure that your products arrive at their destination in optimal condition.

By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of physical damage to your products and enhance their overall quality and safety.

If you are interested in safe and proper packaging, then partner with Brown Packaging today to get started.

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping,

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is

Home » Strategies to Protect Packaging Against Physical Damage

In shipping large quantities of goods, ensuring the safety and stability of pallet loads is paramount. Edge protectors play a vital role in protecting palletized shipments from damage during transportation and handling. This blog explores how edge protectors enhance the security of pallet loads, their types, and the benefits they bring to logistics and supply chains. What Are Edge Protectors? Edge protectors, also known as corner protectors, are sturdy materials placed along the edges of palletized loads to provide reinforcement and protection. Typically made from plastic, corrugated, or foam materials, edge protectors prevent damage to packaging and products during strapping, stacking, and transit. They come in various sizes, thicknesses, and shapes, such as L-shaped or flat, to suit different load configurations. Types of Edge Protectors Plastic Edge Protectors Material: High-density polyethylene (HDPE). Uses: Ideal for securing heavy pallet loads. Benefits: Strong and durable, resistant to moisture and impact, and reusable. Corrugated Edge Protectors Material: Sturdy corrugated board. Uses: Suitable for eco-conscious businesses or lighter palletized goods. Benefits: Lightweight, recyclable, and customizable in length and thickness. Foam Edge Protectors Material: Shock-absorbing foam. Uses: Best for fragile or sensitive products on pallets. Benefits: Provides superior cushioning against impacts and vibrations during transport. Benefits of Edge Protectors for Pallet Loads Enhanced Stability Edge protectors help secure straps tightly around palletized loads, reducing the risk of movement or shifting during transportation. This stability minimizes the likelihood of toppled pallets and damaged products. Prevents Strap Damage Tensioned straps can dig into packaging, causing tears or deformation. Edge protectors distribute the pressure evenly across the load, safeguarding both the packaging and the products inside. Improved Load Integrity By reinforcing the corners and edges of a pallet load, edge protectors prevent crushing and damage, particularly for cartons stacked at the bottom of the pallet. Reduced Shipping Costs Minimizing damage to goods lowers the risk of returns and replacements, reducing overall shipping expenses and improving profit margins. Streamlined Stacking and Storage Edge protectors maintain the structural integrity of stacked pallets, allowing for safe and efficient storage in warehouses or during transit. Enhanced Sustainability Corrugated edge protectors are biodegradable and recyclable, making them an eco-friendly choice for businesses aiming to reduce their environmental impact. Protection Against Legal Liability Properly secured pallet loads with edge protectors demonstrate due diligence in product safety, reducing the risk of legal disputes over damaged goods during transportation. Customization for Pallet Loads Edge protectors can be customized to fit the unique requirements of palletized shipments: Length and Thickness: Tailor edge protectors to match pallet dimensions and load weight. Materials: Choose foam for fragile products or plastic for heavier loads. Branding: Add logos or company branding for enhanced visibility and professional presentation. Conclusion Edge protectors are indispensable for protecting palletized goods during shipping, ensuring stability, reducing damage, and lowering costs. They provide a cost-effective solution to safeguard products, maintain load integrity, and enhance overall operational efficiency. Interested in stock or custom edge protectors for palletized loads? Contact Brown Packaging today to explore options tailored to your business needs. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Edge Protectors Facebook Twitter LinkedIn Pinterest Relevant Posts

The world of packaging is an intricate system of components working together to ensure products reach consumers in pristine condition. Many packaging elements such as tape, stretch film, or boxes are commonplace in our daily lives. However, in the grand scheme of packaging, one hero often goes unnoticed: the humble edge protector. This article aims to shine a spotlight on the essential but underappreciated role of edge protectors in the realm of packaging. The Fundamentals: What are Edge Protectors? Edge protectors, often referred to as corner protectors, edge guards, or angle boards, are industrial packaging materials designed to safeguard the corners and edges of goods during storage and transportation. They are usually made from sturdy materials like plastic, metal, or most commonly, recycled cardboard. Edge protectors may appear straightforward and mundane, but they hold the essential task of shielding the products from harm and ensuring secure delivery. The Critical Role of Edge Protectors in Packaging Edge protectors are not just additional packaging components; they’re integral to maintaining the integrity of the packaged goods. Here’s why: Damage Prevention The primary purpose of edge protectors is to shield the vulnerable corners and edges of products from damage during transit. By reinforcing these vulnerable points, they decrease the likelihood of the product being affected by impacts, vibrations, or abrasions. Load Stability Edge protectors help maintain the stability of palletized goods during transit. They enable better load distribution and prevent shifting or toppling of products, making transport safer and more efficient. Strapping Protection Edge protectors also act as a buffer between strapping materials and the product, distributing the pressure applied by strapping evenly and preventing indentation or damage to the product. Enhanced Product Image By minimizing the risk of product damage, edge protectors indirectly contribute to preserving a company’s reputation. Receiving goods in perfect condition enhances customer satisfaction, promoting a positive product and brand image. The Environmental Impact: Sustainability in Focus An often-overlooked aspect of edge protectors is their contribution to sustainable packaging practices. Many edge protectors, especially those made from recycled cardboard, align with the push towards eco-friendly packaging. They are recyclable and biodegradable, reducing the overall environmental footprint of packaging. Thus, the use of edge protectors aligns with the growing consumer demand for sustainable business practices. The Economic Perspective: Cost-Efficiency in Packaging Edge protectors are cost-effective packaging solutions. They reduce the risk of product damage and associated costs of replacements or refunds. By ensuring load stability, they allow more efficient use of transportation space, saving costs in the long run. Moreover, being made from cost-effective materials like recycled cardboard, they don’t add significantly to the overall packaging expenses. Conclusion: The True Value of Edge Protectors In the world of packaging, it’s easy to overlook the quiet contributors like edge protectors. However, their role in preventing damage, promoting sustainability, and enhancing cost efficiency is invaluable. They may be unsung heroes, but the quality of the product delivery wouldn’t be the same without them. As we strive towards creating efficient, sustainable packaging solutions, the significance of edge protectors is likely to grow even more. So, the next time you see a shipment arrive in pristine condition, take a moment to appreciate the hidden champions of packaging: the edge protectors. If your interested in edge protectors, stock or custom, the contact Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Stock Edge Protectors Facebook Twitter LinkedIn Pinterest Relevant Posts

In our daily lives, we come across a plethora of pharmaceutical products, either in our personal capacity or via someone close to us. In this blog, we will delve into a significant yet frequently overlooked component of these products: blister packs. We will explore their utility, benefits, and why the pharmaceutical industry is heavily dependent on them. Understanding Blister Packs Before delving into the specifics of the pharmaceutical industry’s dependence on blister packs, let’s first understand what they are. A blister pack is a type of packaging produced by sealing a product in a plastic cavity or pocket, usually with a paper, corrugated, or foil backing. They’re commonly used for packaging pharmaceutical products, particularly pills, tablets, and capsules. Why Blister Packs? So, why does the pharmaceutical industry prefer blister packs over other packaging options? The simple answer is the versatility, protection, and convenience that blister packs offer. Protection and Preservation Blister packs are predominantly used because they protect the individual doses of medication. They offer a barrier to moisture, light, and oxygen, preserving the effectiveness of the drugs. The separation of each pill also prevents cross-contamination and ensures that the product remains tamper-evident until it reaches the end consumer. Patient Compliance and Safety A significant benefit of blister packaging lies in patient compliance. The organized and segmented nature of blister packs allows patients to track their medication intake effectively. It can significantly aid elderly patients or those taking multiple medications at different times of the day. By reducing errors in medication consumption, blister packs enhance patient safety. Ease of Use and Portability Blister packs are designed for consumer convenience. They are lightweight, compact, and easily portable, making them ideal for on-the-go consumers. The simplicity in popping a pill out from its compartment enhances the product’s ease of use. The Business Perspective: Cost-Effectiveness and Marketing Opportunities From the business side, blister packs offer several benefits, including cost-effectiveness and marketing opportunities. Cost-Effectiveness Blister packaging can be highly cost-effective compared to other packaging solutions. The material used is typically less expensive, and the production process is often more streamlined. Also, because blister packs help maintain drug integrity, the rate of product returns or losses due to spoilage or damage is substantially reduced. Marketing Opportunities Lastly, blister packs offer unique marketing opportunities. The backing card provides ample space for branding, important drug information, instructions for use, and even promotional messages. This aspect can give pharmaceutical companies an edge in a highly competitive market. Environmental Considerations of Blister Packs Like any industry, pharmaceutical packaging must consider its environmental impact. While blister packs provide a multitude of benefits, they also have some downsides. These packs are often composed of a combination of plastic and aluminum, which are not biodegradable and difficult to recycle. As environmental awareness rises, pharmaceutical companies are challenged to find more sustainable solutions without compromising the product’s integrity and the consumer’s safety and convenience. The Future of Blister Packs in Pharmaceuticals With the advantages blister packs offer, they’re here to stay. However, the push for more sustainable practices is driving innovation in this sector. We can expect advancements in materials science to produce more environmentally-friendly blister packs in the future. Furthermore, technology may introduce smart blister packs, capable of reminding patients to take their medication, improving adherence rates even further. In summary, the pharmaceutical industry’s dependence on blister packs is multifaceted and rooted in both practical and business considerations. However, as the industry evolves, so too will its packaging methods, with an increasing focus on sustainability and technological innovation. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Blister Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts