Home » Why Rigid Boxes are More Costly Than Alternatives

Why Rigid Boxes are More Costly Than Alternatives

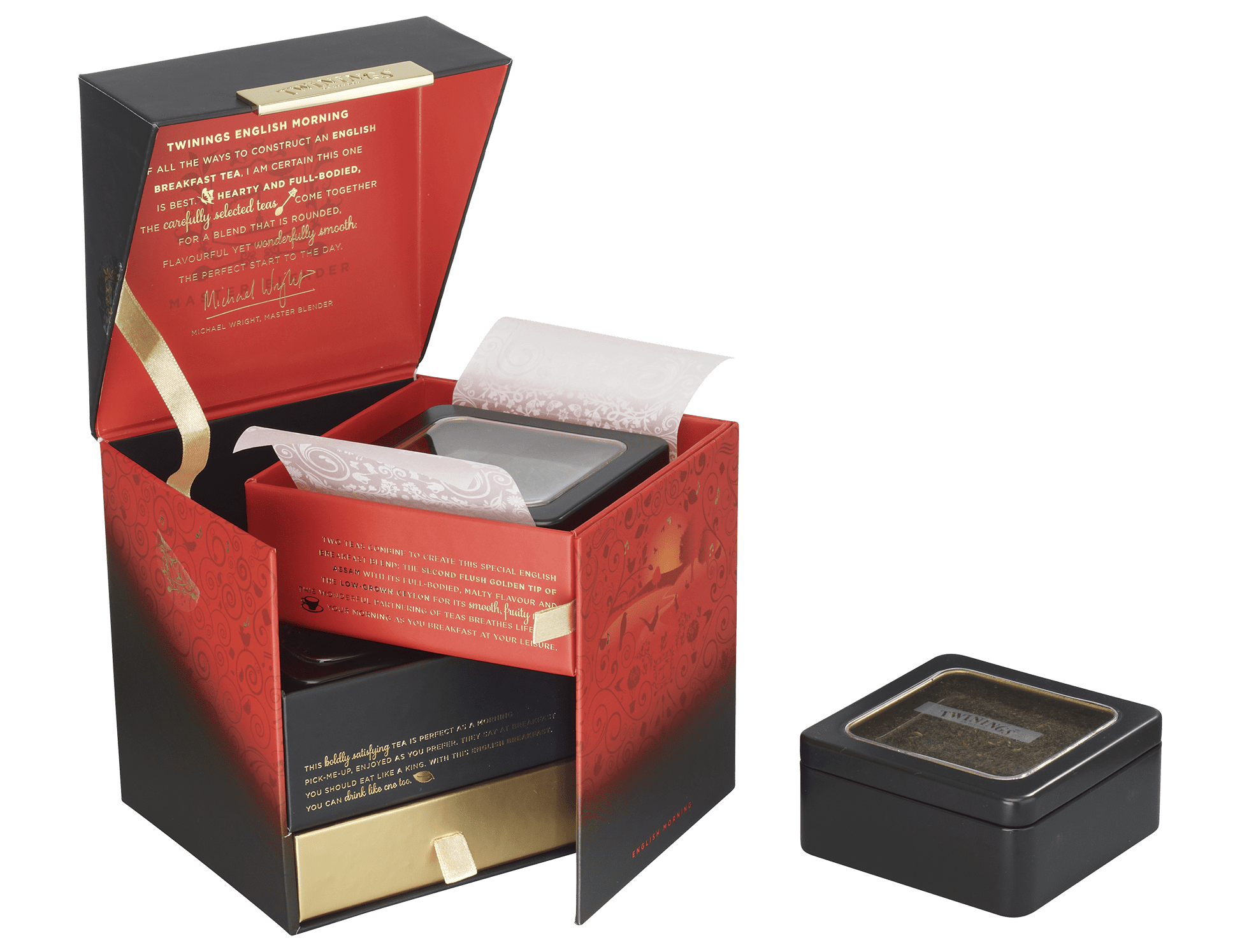

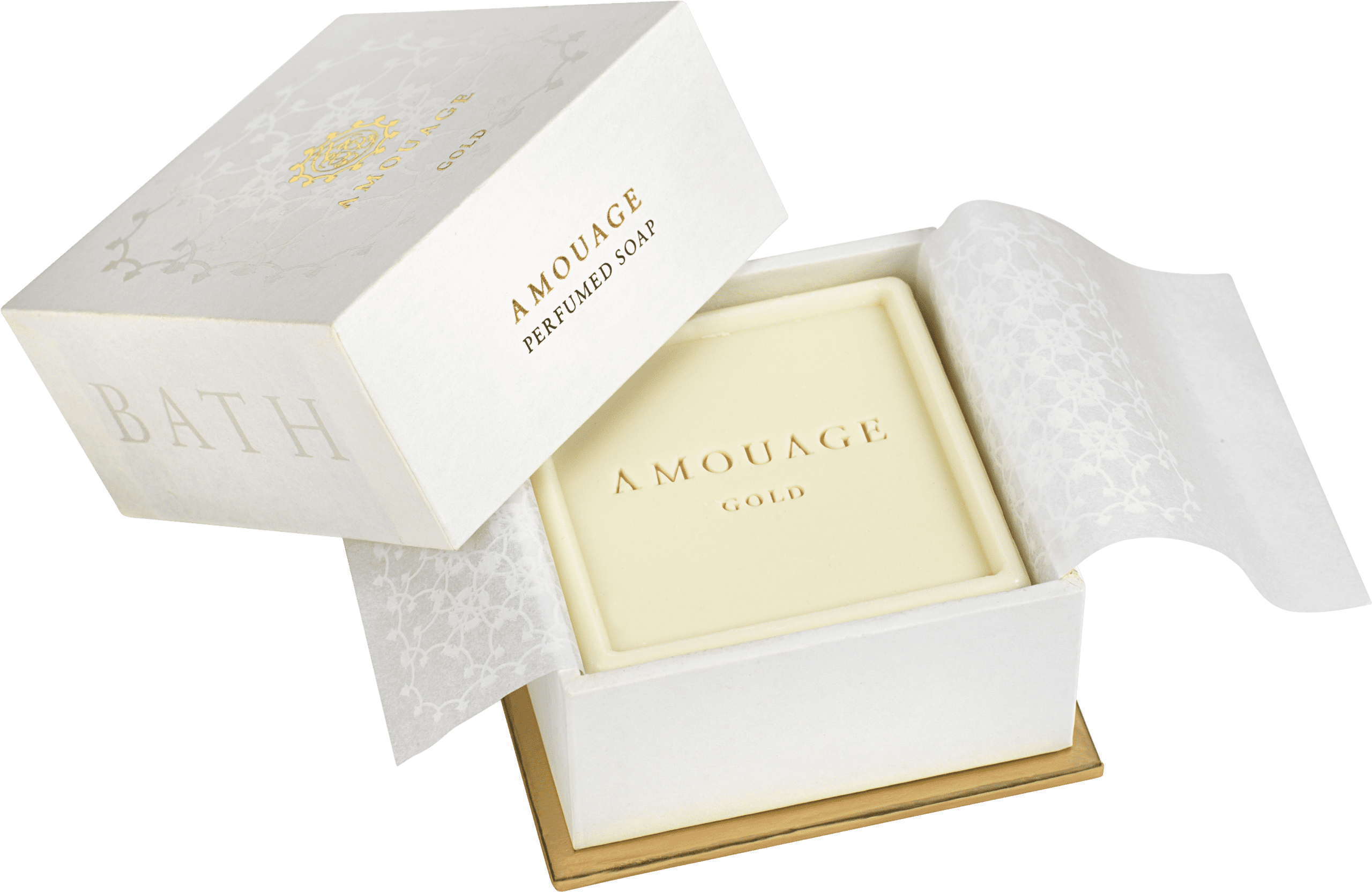

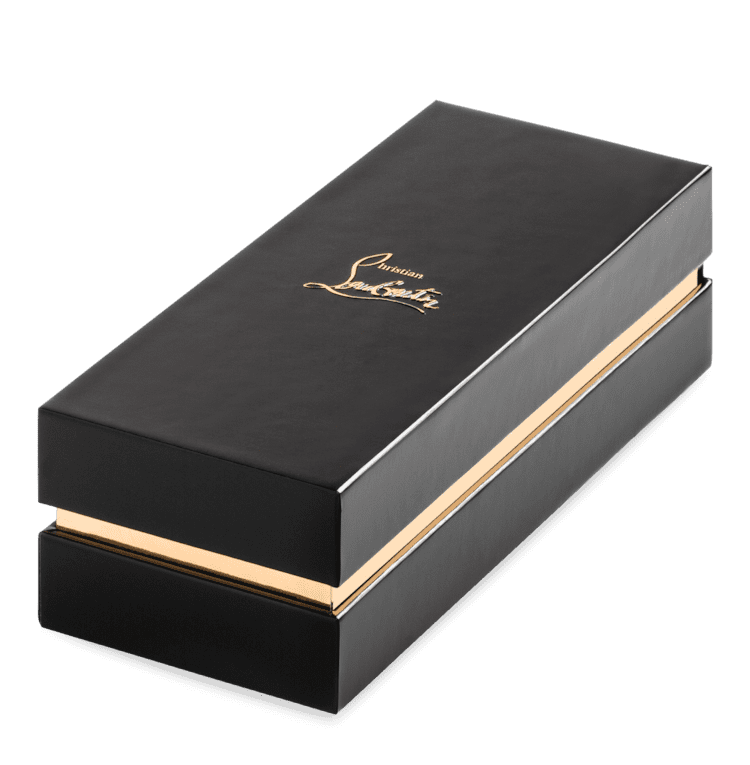

Rigid boxes, also known as set-up boxes, are high-quality packaging boxes that offer an unmatched level of durability and sturdiness. They are often used for luxury products like cosmetics, electronics, and other high-end products that require extra protection during shipping and handling. While rigid boxes are known for their superior quality, they can be more costly than alternatives.

In this blog, we will explore why rigid boxes are more expensive than people think and what factors contribute to their higher cost.

Why Rigid Boxes Are Costly

Material Costs

One of the primary reasons why rigid boxes are more expensive than alternatives is the cost of the materials used to make them. Unlike regular corrugated boxes, rigid boxes are made from thicker and sturdier materials, such as heavier gauge chipboard. These materials are more expensive than regular cardboard, and the thickness of the material increases the cost of the box further. In addition, rigid boxes often require additional materials, such as foam inserts or magnetic closures, which can increase the overall cost of the box.

Production

Rigid boxes require a more complicated manufacturing process than regular cardboard boxes. The production process involves several steps, including cutting, folding, gluing, and assembly, which require specialized machinery and skilled labor. The production process for rigid boxes is more time-consuming and requires more manual labor, which adds to the overall cost of the box.

Customization

Rigid boxes are often used for high-end products that require a unique and personalized packaging solution. Customization options like embossing, debossing, foil stamping, and printing can add to the cost of the box. The cost of customization depends on the complexity of the design, the number of colors used, and the printing method used. In addition, the cost of customization increases with the size of the box, making larger boxes more expensive to customize.

Shipping Costs

Rigid boxes are heavier and bulkier than regular cardboard boxes, which can increase the cost of shipping. The additional weight and size of the box can also affect the cost of storage and warehousing.

Brand Value

Finally, the brand value associated with rigid boxes can also add to the overall cost. Rigid boxes are often associated with high-end products and luxury brands, and the premium packaging can enhance the overall customer experience. While the cost of the box may be higher, the perceived value of the product is also higher, which can justify the increased cost.

Minimum Order Quantity

Rigid boxes are often custom-made, which means that there may be a minimum order quantity (MOQ) requirement. The MOQ can vary depending on the size, material, and customization options of the box. A higher MOQ can increase the overall cost of the box, especially if you don’t need a large quantity.

Design Costs

If you don’t have an existing packaging design, you may need to hire a graphic designer or packaging specialist to create a design that fits your brand and product. Design costs can add to the overall cost of the box, especially if you require a complex or detailed design.

Storage and Warehousing Costs

Rigid boxes are bulkier than regular cardboard boxes, which can affect the storage and warehousing costs. If you’re ordering a large quantity of rigid boxes, you may need to find additional storage space to keep them until they’re ready to be shipped. Storage and warehousing costs can add to the overall cost of the box, especially if you’re working with a tight budget.

When Should You Invest in a Rigid Box?

When it comes to packaging, choosing the right box for your product is crucial for its protection during shipping and handling, as well as for the overall customer experience. While rigid boxes may be more expensive than regular cardboard boxes, there are several instances when investing in a rigid box can be a worthwhile investment for your product.

Here are some of the scenarios when you should consider investing in a rigid box:

High-End Products

If you’re selling high-end products like luxury cosmetics, electronics, or other premium products, a rigid box is an excellent investment to enhance the overall customer experience. Rigid boxes offer a premium and sophisticated look and feel, which can increase the perceived value of the product.

Fragile or Heavy Products

If your product is fragile or heavy, a rigid box can provide the necessary protection during shipping and handling. The thick and sturdy material of rigid boxes can prevent damage or breakage, which can save you money in the long run by reducing the number of damaged or returned products.

Customization Needs

If you want to create a unique and personalized packaging solution for your product, a rigid box is an excellent choice. Rigid boxes offer a variety of customization options, including embossing, debossing, foil stamping, and printing. These customization options can help you create a packaging design that reflects your brand and enhances the overall customer experience.

Retail Display Needs

If your product will be displayed in a retail store, a rigid box can provide a more professional and polished look than regular cardboard boxes. Rigid boxes are sturdy and can be customized with your brand’s logo and design, making them an excellent choice for retail displays.

Reusability

Rigid boxes are durable and can be reused, making them a sustainable choice for packaging. If you’re selling a product that has a long shelf life or can be repurposed, a rigid box can be a great investment, as customers are more likely to keep the box and reuse it for storage or other purposes.

Product Differentiation

Investing in a rigid box can help your product stand out on the shelf and differentiate it from competitors. By customizing your rigid box with unique design elements, such as embossing or foiling, you can create a packaging solution that reflects your brand and product and captures the attention of consumers.

If you are interested in rigid boxes or more cost-effective alternatives for your product, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Why Rigid Boxes are More Costly Than Alternatives

Rigid boxes, also known as set-up boxes, are high-quality packaging boxes that offer an unmatched level of durability and sturdiness. They are often used for

Rigid boxes are the premium standard in packaging—perfect for luxury products, high-end electronics, skincare, and gift sets. But creating a beautiful rigid box is only

Rigid boxes, known for their durability and premium appearance, are a popular choice for packaging high-end products. However, the perception of being expensive can deter