Home » Two-Piece vs. Three-Piece Bike Shipping Boxes

Two-Piece vs. Three-Piece Bike Shipping Boxes

When it comes to shipping bikes, selecting the right type of corrugated box is essential to ensure product protection, ease of handling, and cost efficiency. Two of the most common packaging styles for bicycles are two-piece and three-piece bike boxes, each offering unique benefits depending on shipping requirements and handling preferences. Below, we compare the differences to help determine which option is best suited for your needs.

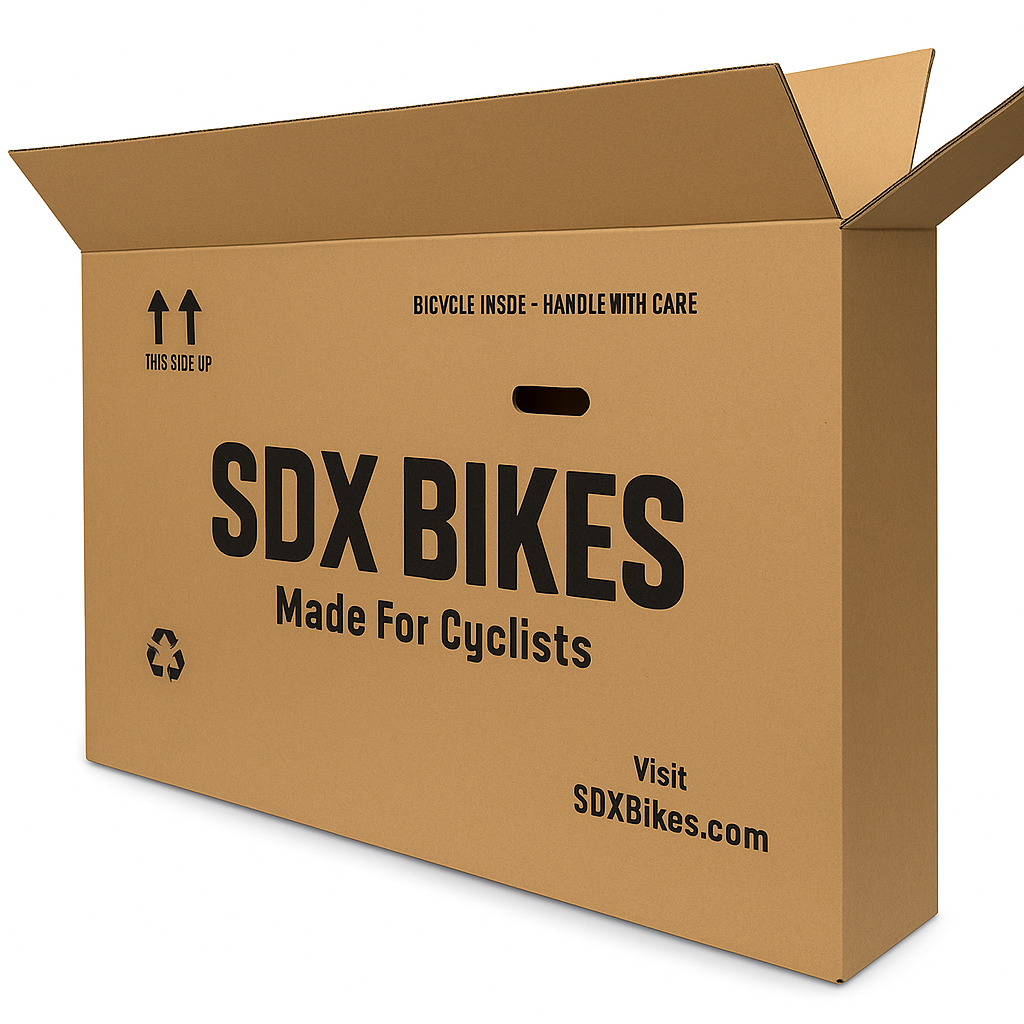

What is a Two-Piece Bike Shipping Box?

A two-piece bike box consists of a base and a lid, designed to securely enclose the bike with a snug fit. This structure provides:

- Easy Access & Assembly – The bike can be placed in the bottom half of the box, and the top half easily covers it, making packaging and unpackaging simple.

- Strong Structural Support – With a well-designed fit, these boxes reduce movement inside, offering better stability during transit.

- More Compact & Efficient – Since it consists of only two parts, it requires fewer materials, making it a cost-effective solution for standard bike shipping.

- Best for Pre-Assembled or Partially Assembled Bikes – Ideal for retail-ready shipments, allowing bikes to be securely packed and ready for quick assembly by the end user.

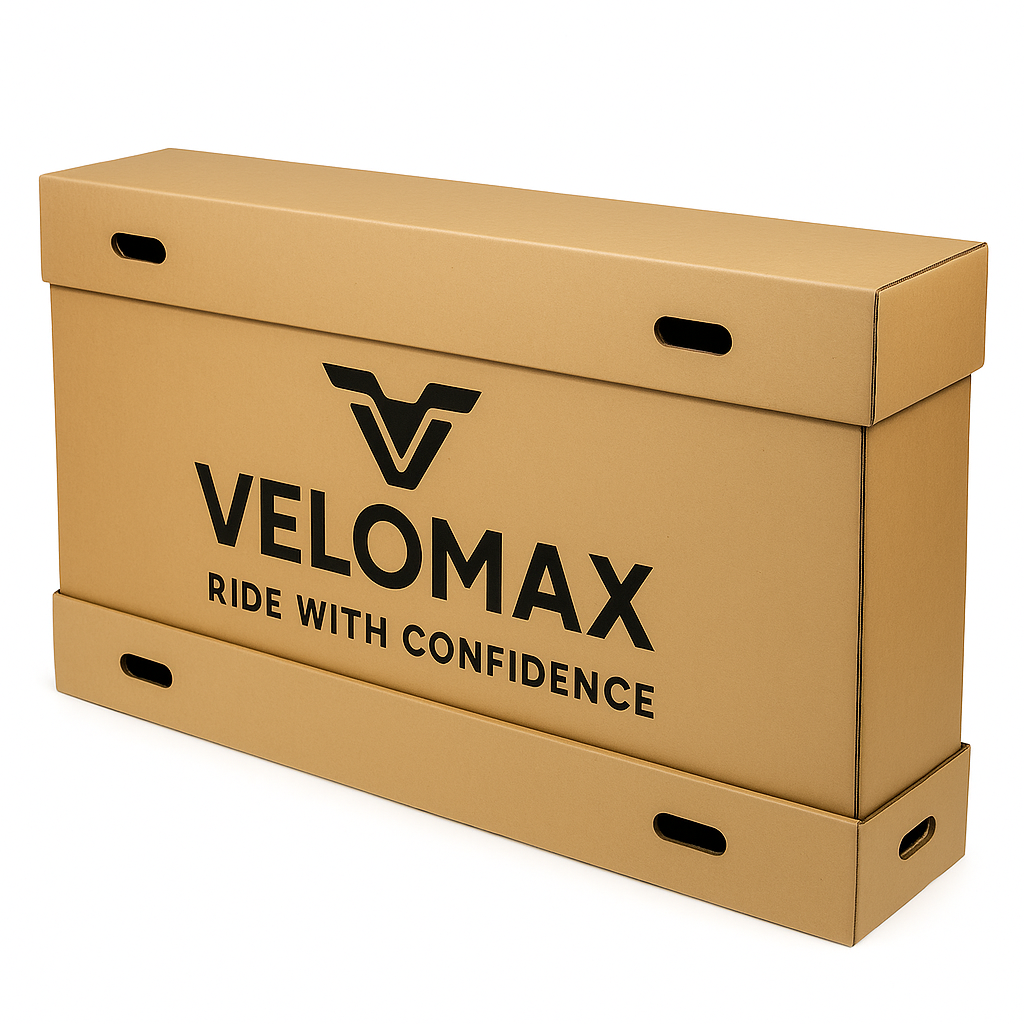

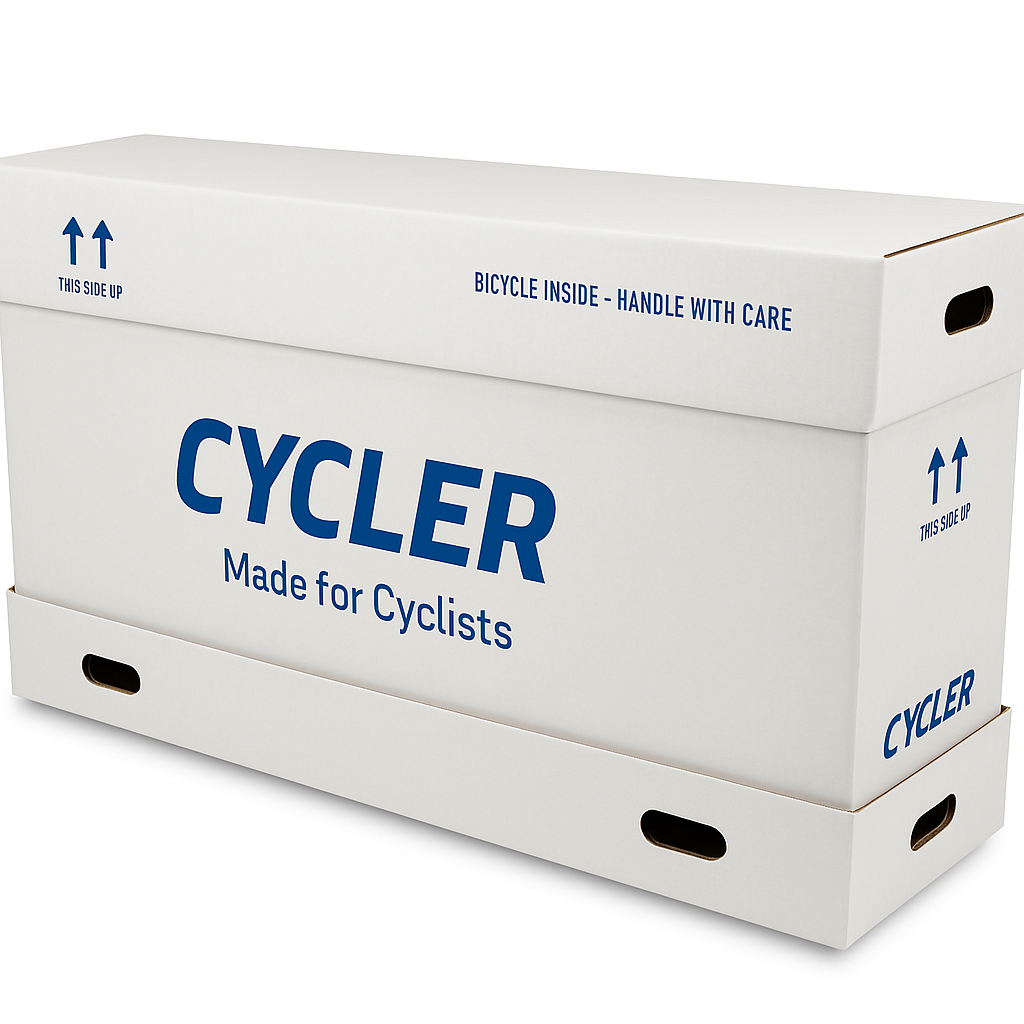

What is a Three-Piece Bike Shipping Box?

A three-piece bike box includes a base, lid, and an additional sleeve that wraps around the bike, offering enhanced adjustability and protection. This design provides:

- Enhanced Protection & Customization – The sleeve allows for better compression resistance and added durability, reducing the risk of damage.

- Adjustable Height for Different Bike Sizes – The sleeve can expand or contract, accommodating various bike dimensions without needing separate box sizes.

- Increased Stability for Long-Distance Shipping – Extra layers of corrugated board help protect the bike from external impacts, stacking pressure, and handling wear.

- Ideal for High-End or Specialty Bikes – Often used for luxury, electric, or performance bikes, where additional reinforcement is necessary.

Key Differences Between Two-Piece and Three-Piece Bike Boxes

Feature | Two-Piece Box | Three-Piece Box |

Components | Base + Lid | Base + Lid + Sleeve |

Protection Level | Standard – Good for general shipping | High – Ideal for fragile or premium bikes |

Assembly | Quick and simple | Requires extra steps but offers better adjustability |

Material Usage | Less material – more cost-effective | More material – extra durability and protection |

Best For | Standard bikes, eCommerce, retail shipments | High-end, electric, or international bike shipments |

Which Bike Shipping Box is Right for You?

The choice between a two-piece and three-piece bike box depends on your shipping conditions, bike type, and budget:

- Choose a Two-Piece Box if you need a cost-effective, easy-to-assemble solution for standard bike shipping.

- Opt for a Three-Piece Box if you require added protection, flexibility in sizing, and superior durability for long-haul or high-value shipments.

Custom Solutions for Bike Packaging

Both two-piece and three-piece bike boxes can be customized with reinforced inserts, foam padding, printed branding, and special coatings to enhance protection and brand visibility. If you’re unsure which option suits your needs, our team can help design a custom packaging solution tailored to your specific bike shipping requirements.

Contact Brown Packaging today to find the perfect bike shipping box for your business!

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are learning that premium doesn’t always

Home » Two-Piece vs. Three-Piece Bike Shipping Boxes