Home » Tiered Packaging Explained

Tiered Packaging Explained

In the world of retail and e-commerce, packaging isn’t just about protecting products; it’s an essential part of the overall customer experience. One effective strategy to enhance this experience is tiered packaging. This approach involves offering premium packaging options for select products or customers, allowing you to cater to different preferences and elevate your brand’s image. In this detailed blog, we will explore the concept of tiered packaging and its benefits for businesses looking to provide a personalized and memorable unboxing experience.

Understanding Tiered Packaging

Tiered packaging is a strategic approach that involves creating multiple levels of packaging options, each catering to specific customer segments or product categories. These tiers typically include:

- Standard Packaging: The basic packaging option suitable for most products. It focuses on functionality and cost-efficiency.

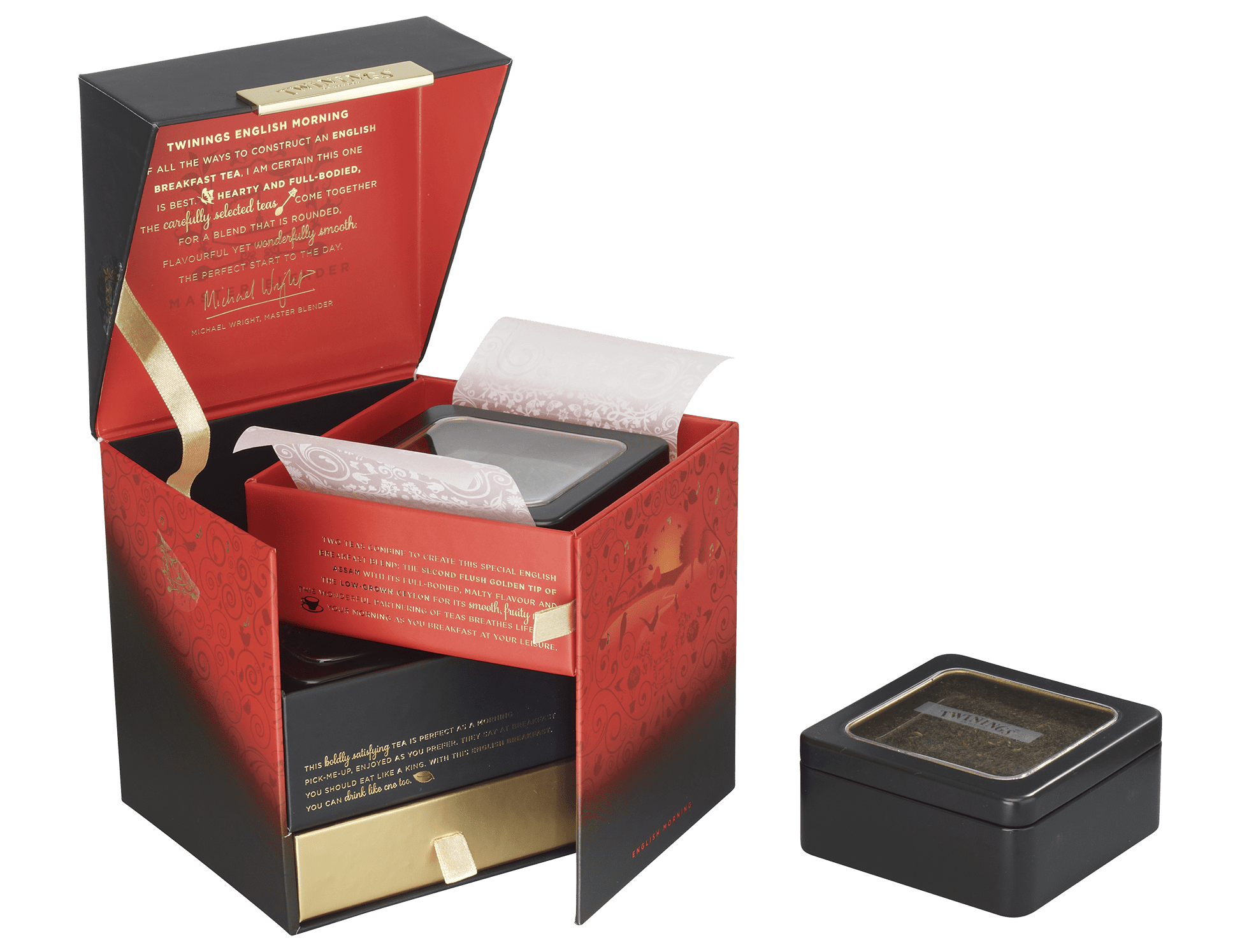

- Premium Packaging: A higher-quality packaging option that adds a touch of luxury and sophistication to the unboxing experience. It often includes features like embossing, foiling, or special finishes.

- Custom Packaging: Tailored packaging solutions designed for specific products or occasions. Custom packaging can be highly personalized, reflecting the uniqueness of the product or event.

Benefits of Tiered Packaging

Tiered packaging offers numerous advantages for businesses looking to stand out in a competitive market:

- Personalization: By offering different packaging tiers, you can tailor the unboxing experience to the preferences and expectations of different customer segments. This personalization can create a stronger emotional connection with your brand.

- Brand Image: Premium and custom packaging options enhance your brand’s image, positioning it as upscale and attentive to detail. This can influence how customers perceive your products and brand.

- Customer Loyalty: Providing a premium unboxing experience can foster loyalty among your customers. They are more likely to return to a brand that consistently delivers a memorable and personalized experience.

- Increased Perceived Value: Premium packaging elevates the perceived value of your products. Customers are willing to pay more for items that come in high-quality packaging.

- Unboxing Excitement: Premium and custom packaging options create a sense of excitement during unboxing. This excitement can lead to positive unboxing videos and social media shares, providing free marketing and exposure.

- Versatility: Tiered packaging allows you to adapt to various occasions and product categories. You can offer different packaging options for regular product lines, seasonal promotions, limited-edition releases, and special events.

Implementing Tiered Packaging

Here are the key steps to implement tiered packaging effectively:

- Segment Your Audience: Identify distinct customer segments based on factors like purchasing behavior, demographics, or loyalty levels. Understand the unique preferences and expectations of each segment.

- Define Packaging Tiers: Create packaging tiers that align with your brand and the identified customer segments. Determine the features, materials, and finishes that differentiate each tier.

- Product Selection: Decide which products or product categories will be eligible for each packaging tier. Consider factors like product value, profit margin, and target audience.

- Pricing Strategy: Set pricing for each packaging tier. Ensure that the added cost of premium or custom packaging aligns with the perceived value it brings to the customer.

- Promotion and Communication: Promote your tiered packaging options through marketing channels and on your website. Clearly communicate the benefits of each tier and who it is designed for.

- Consistency: Maintain consistency in your packaging options and branding across all touchpoints, from the website to the unboxing experience. Consistency reinforces your brand identity.

Conclusion

Tiered packaging is a powerful strategy that allows businesses to offer a personalized and memorable unboxing experience while enhancing their brand image. By segmenting your audience, defining packaging tiers, selecting eligible products, setting pricing, and effectively promoting your options, you can create a packaging strategy that resonates with different customer segments and drives customer loyalty. Ultimately, tiered packaging is a valuable tool for businesses looking to stand out and create lasting impressions in today’s competitive market.

If you are interested in tiered packaging solutions, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Tiered Packaging Explained

Venture into a sizable retail store, roam the pathways of an expansive warehouse, or take a behind-the-scenes glance at a bustling e-commerce fulfillment center, and

Corrugated boxes are a staple in the packaging world, known for their strength and versatility. However, maximizing their durability is key to ensuring products reach

Packaging for toddler toys is a unique segment that requires a thoughtful approach, balancing safety, engagement, and often, an educational aspect. This blog post explores