Home » Thermoform Packaging on Product Safety and Shelf-Life

Thermoform Packaging on Product Safety and Shelf-Life

The world of packaging has seen tremendous innovation over the years. With the increasing emphasis on product safety, hygiene, sustainability, and overall aesthetic appeal, manufacturers have adopted various modern packaging techniques. One such technique is thermoform packaging, a method widely recognized for its beneficial impacts on product safety and shelf-life.

Understanding Thermoform Packaging

Definition and Procedure

Thermoform packaging involves the use of heat to mold plastic sheets into specific shapes that accommodate a product perfectly. The process involves heating a plastic sheet until it reaches a pliable state, then molding it around a specific form and cooling it. This provides a secure packaging solution that maintains the integrity of the enclosed product.

Types of Thermoform Packaging

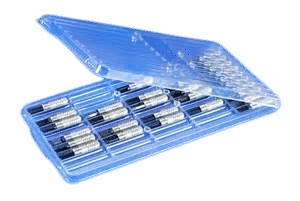

There are several types of thermoform packaging, including clamshells, blister packs, and trap packs. These diverse types allow for a wide range of applications across different industries, including food, pharmaceuticals, and electronics, among others.

Impact on Product Safety

Enhanced Protection

One of the primary benefits of thermoform packaging is that it offers superior product protection. The plastic molding process creates a snug, custom fit around the product, reducing the risk of movement and potential damage during transit. Furthermore, the rigid exterior of the packaging shields the product from external impact, ensuring its safety.

Barrier Properties

Thermoform packaging provides an excellent barrier against external factors such as moisture, dust, and bacteria, ensuring the product within remains uncontaminated. This is particularly critical in food and pharmaceutical packaging, where the intrusion of such elements could lead to product spoilage and pose serious health risks.

Impact on Shelf-Life

Preservation and Freshness

The impermeability of thermoform packaging to gases like oxygen and carbon dioxide has a significant impact on product shelf-life. By preventing exposure to oxygen, this form of packaging slows down oxidation reactions, reducing food spoilage rates and maintaining freshness for longer.

Reduced Product Waste

As a consequence of the extended shelf-life, thermoform packaging also reduces product waste. With longer periods of freshness and usability, consumers have more time to use products before their expiration date, leading to less waste.

Additional Benefits of Thermoform Packaging

Visibility

Thermoform packaging, especially types like clamshells and blister packs, provide excellent product visibility. This is beneficial from a marketing perspective, as customers can see the product without opening the package.

Customization

Thermoform packaging allows for high levels of customization. Businesses can create unique packaging shapes that not only fit their product perfectly but also enhance brand recognition and appeal.

Sustainability

Despite the plastic component, many thermoform packages are recyclable, which reduces the environmental impact. Companies are also exploring biodegradable and plant-based plastics for thermoforming, aligning with the global push for sustainability.

Conclusion: A Significant Contribution to Product Safety and Shelf-Life

The benefits of thermoform packaging on product safety and shelf-life are undeniable. Through enhanced protection, superior barrier properties, and extended product freshness, thermoform packaging ensures that products reach consumers in the best possible condition. Its added benefits of customization, visibility, and potential for sustainability make it a compelling choice in the packaging world.

If you are interested in thermoform packaging, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Thermoform Packaging on Product Safety and Shelf-Life

High Impact Polystyrene, commonly known as HIPS, is a versatile and widely used thermoplastic renowned for its unique blend of properties. This material is crucial

Thermoform inserts are a versatile and essential component in various industrial and consumer applications. They are produced through a process called thermoforming, where a plastic

In our daily lives, we come across a plethora of pharmaceutical products, either in our personal capacity or via someone close to us. In this