Home » The Role of Protective Packaging in Reducing Product Damage

The Role of Protective Packaging in Reducing Product Damage

Packaging is an integral part of the overall customer experience, providing protection, information, and branding to the products we buy. However, when it comes to shipping goods, the protective aspect of packaging becomes increasingly crucial. This blog will delve into the role of protective packaging in reducing product damage during transport and storage.

Understanding Protective Packaging

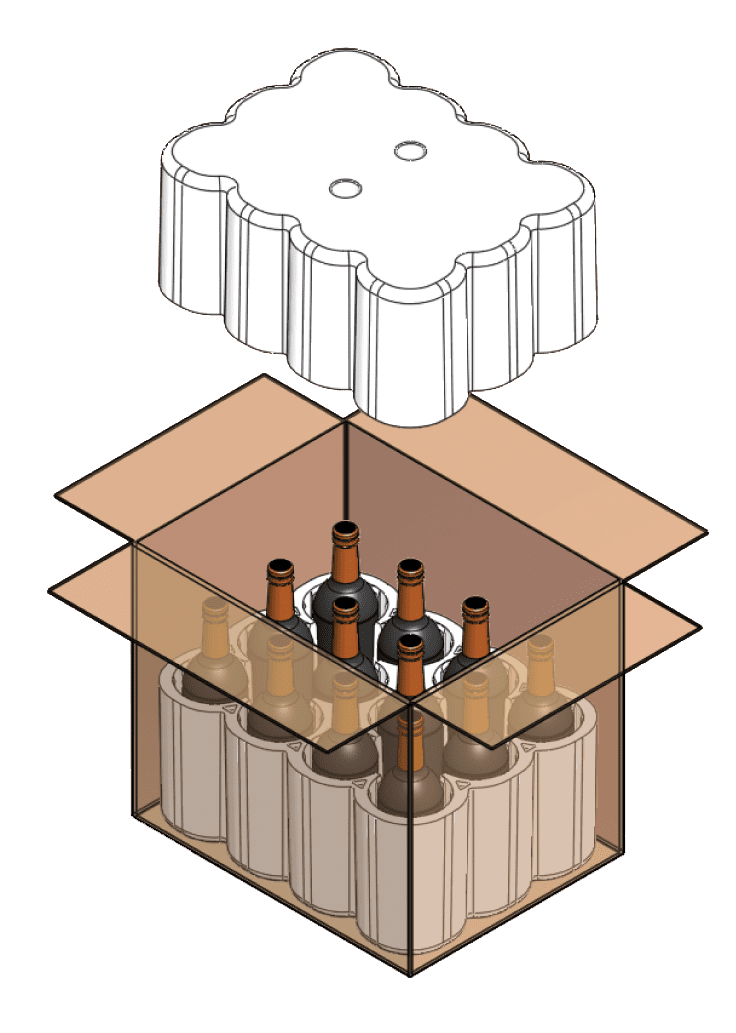

Before we can fully understand the role protective packaging plays in reducing product damage, it’s crucial to know what it is. Protective packaging, as the name implies, is designed to safeguard products from damage during shipment and storage. This can include materials such as bubble wrap, foam inserts, air pillows, corner protectors, and many other types of specialized packaging.

The primary goal of protective packaging is to ensure that a product arrives at its destination in the same condition as when it left the warehouse or factory. It achieves this by absorbing shocks, preventing scratches or scuffs, and protecting against environmental factors such as moisture or temperature changes.

The Impact of Product Damage

Product damage can have far-reaching effects beyond the immediate financial loss of the product itself. These can include:

- Negative customer experience: A damaged product is likely to lead to an unhappy customer, which can result in negative reviews and lower repeat business.

- Increased costs: Besides the obvious cost of the damaged product, there can be additional costs associated with returns, replacements, and potentially even compensation for the customer.

- Brand reputation: Regular occurrences of damaged products can harm a company’s reputation, leading to a loss of trust and potential customers.

- Environmental impact: Damaged products often end up in landfills, contributing to environmental pollution.

Given these impacts, it’s clear why protective packaging is so important.

The Role of Protective Packaging in Damage Reduction

Protective packaging plays a key role in damage reduction in several ways:

Cushioning and Shock Absorption

This is perhaps the most obvious role. Materials such as bubble wrap, foam inserts, or inflatable air pillows provide a buffer around the product, absorbing any shocks or impacts that may occur during transit. This can prevent breakages, dents, and other physical damage.

Filling Void Spaces

Protective packaging such as packing peanuts or paper can fill the empty space in a box, preventing the product from moving around during transit. This can protect against scratches, scuffs, or other damage caused by the product colliding with the sides of the box.

Protection from Environmental Factors

Some types of protective packaging, such as barrier bags, can protect against environmental factors such as moisture, dust, or temperature changes. This can be crucial for products that are sensitive to these factors, such as electronics or certain types of food.

The Future of Protective Packaging

As technology evolves, so too does protective packaging. Innovations such as intelligent packaging systems are able to detect and alert when a package has been dropped or mishandled. Biodegradable and recyclable protective packaging options are also becoming more popular, helping to reduce the environmental impact of packaging.

If you are interested in protecting your products effectively, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » The Role of Protective Packaging in Reducing Product Damage

Score cracking—visible fiber breakage along a fold—can ruin a carton’s appearance, weaken its structure, and cause failures on automated lines. Understanding the causes and engineering

In shipping large quantities of goods, ensuring the safety and stability of pallet loads is paramount. Edge protectors play a vital role in protecting palletized

When it comes to packaging fragile or valuable items, ensuring their safe transportation is crucial. One effective way to protect these items during shipping or