Home » The Pros and Cons of Tariffs on Packaging

The Pros and Cons of Tariffs on Packaging

With tariffs set to reshape the U.S. packaging industry in 2025, packaging buyers must understand their potential benefits and challenges. Tariffs aim to encourage domestic sourcing and manufacturing, but their effects can be complex. This blog examines the pros and cons of tariffs for packaging buyers, offering a neutral and informative perspective to help navigate the changing landscape.

What Are Tariffs and How Do They Affect Packaging?

Tariffs are taxes imposed on imported goods, designed to incentivize businesses to source domestically. For the packaging industry, this can lead to increased costs for materials and finished products sourced internationally. At the same time, tariffs may promote local manufacturing and strengthen domestic supply chains.

The Pros of Tariffs on Packaging

Encourages Domestic Manufacturing

Tariffs make imported goods more expensive, driving demand for U.S.-produced materials and packaging products.

Benefits for Buyers:

- Strengthened local supply chains reduce dependency on international markets.

- Shorter transportation distances can improve delivery reliability and speed.

- Opportunities to work with domestic suppliers who align with sustainability and quality standards.

Reduces Exposure to Global Disruptions

The COVID-19 pandemic and other global events highlighted vulnerabilities in international supply chains. Tariffs encourage buyers to source locally, mitigating risks from international shipping delays or geopolitical tensions.

Drives Investment in Innovation

As demand for domestic packaging grows, U.S. manufacturers may invest in new technologies and materials to remain competitive.

Examples of Innovation:

- Development of cost-effective, eco-friendly packaging options.

- Automation to improve production efficiency and reduce lead times.

Potential Environmental Benefits

Local sourcing reduces the need for long-distance shipping, which can lower carbon emissions associated with packaging production and transportation.

The Cons of Tariffs on Packaging

Increased Costs

The most immediate impact of tariffs is higher prices for imported materials and products. These costs can affect buyers in several ways:

- Material Price Increases: Tariffs on imported paperboard, plastics, or aluminum can drive up the cost of packaging solutions like corrugated boxes, flexible films, and beverage cans.

- Pass-Through Costs: Suppliers may pass tariff-related expenses onto buyers, increasing procurement costs.

Supply Chain Bottlenecks

The shift to domestic sourcing can create short-term challenges as manufacturers ramp up to meet increased demand.

Potential Issues:

- Limited production capacity among domestic suppliers.

- Longer lead times due to initial supply shortages.

Limited Supplier Options

In some cases, buyers may struggle to find domestic suppliers offering the same quality, pricing, or product variety as their international counterparts.

Complexity in Procurement

Tariffs add an extra layer of complexity to procurement processes, requiring buyers to:

- Monitor tariff changes and their impacts.

- Evaluate the cost-benefit of domestic vs. international sourcing.

- Navigate customs regulations and compliance requirements for any remaining imports.

Balancing the Pros and Cons

Packaging buyers can weigh the benefits and drawbacks of tariffs by aligning their sourcing strategies with business goals. Consider these key factors:

When Tariffs Can Be a Positive Change:

- Your business values a resilient, local supply chain.

- Sustainability is a priority, and reducing transportation emissions aligns with your goals.

- You’re looking to foster long-term partnerships with domestic manufacturers.

When Tariffs May Pose Challenges:

- Your packaging relies on specialized materials or products not widely available in the U.S.

- Cost increases would significantly impact your pricing or profitability.

- You operate in an industry where margins are already tight.

Preparing for Tariffs in the Packaging Industry

To navigate the impact of tariffs effectively, packaging buyers can take proactive steps to mitigate challenges while capitalizing on opportunities:

- Evaluate Supplier Relationships: Build partnerships with domestic manufacturers to ensure reliable sourcing.

- Invest in Cost Management: Optimize packaging designs and explore alternative materials to reduce expenses.

- Stay Updated: Monitor tariff policies and industry trends to make informed decisions.

- Leverage Technology: Use supply chain management tools to enhance forecasting, inventory management, and sourcing strategies.

Final Thoughts

Tariffs on packaging present a mixed picture for buyers, offering both opportunities and obstacles. While they can drive innovation and strengthen domestic supply chains, they also introduce cost pressures and logistical challenges. By understanding the pros and cons of tariffs and preparing strategically, packaging buyers can adapt to these changes while maintaining operational efficiency.

If you are interested in maximizing the benefits of tariffs on your packaging and limiting the challenges, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

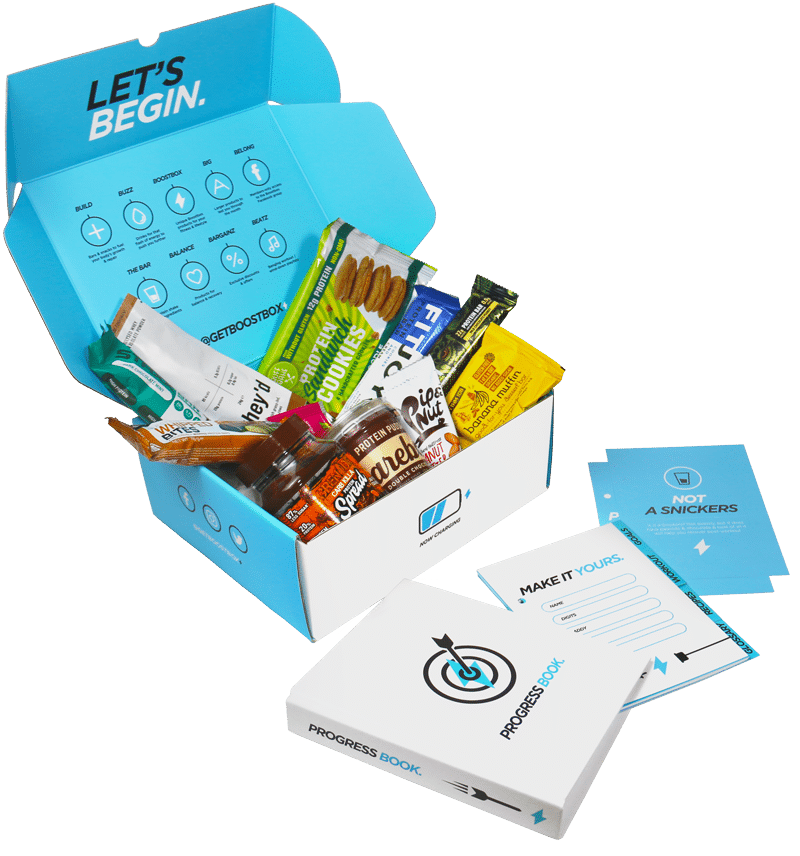

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » The Pros and Cons of Tariffs on Packaging