Home » The Importance of Food Packaging: Understanding Materials, Requirements, and Benefits

The Importance of Food Packaging: Understanding Materials, Requirements, and Benefits

Food packaging is a critical component of the food industry, providing protection, preservation, and marketing benefits for food products. It is an essential element in the supply chain, helping to ensure that food products are safe and of high quality when they reach consumers. Food packaging plays a vital role in maintaining the freshness, flavor, and nutritional value of food products, while also providing convenience, brand recognition, and regulatory compliance.

There are a wide range of food packaging materials and products available, including plastics, paperboard, corrugated materials, and more. Each type of packaging material offers unique benefits and challenges, and businesses must carefully consider their packaging needs when selecting the best packaging options for their products.

In addition to providing functional benefits, food packaging must also comply with strict regulatory requirements set by the FDA and government agencies. These requirements ensure that food packaging is safe and effective, and help to protect the health of consumers.

Overview: Food Packaging Explained

This blog will provide an overview of food packaging, including the reasons why businesses need food packaging, the various types of packaging materials and products available, and the FDA and government requirements that must be met. By understanding the importance of food packaging and the role it plays in the food industry, businesses can make informed decisions about their packaging needs and ensure the safety, quality, and marketability of their food products.

Why Food Packaging Important

Food packaging plays a crucial role in the food industry, providing a variety of benefits to businesses and consumers. Here are some of the main reasons why businesses need food packaging:

Protection

Food packaging protects food products from physical damage, contamination, and spoilage during storage and transportation. This helps to ensure that food products reach consumers in good condition and are safe to eat.

Preservation

Food packaging helps to preserve the freshness, flavor, and quality of food products. Packaging can help to prevent the growth of harmful microorganisms and the oxidation of food products, extending the shelf life and preserving the nutritional value of food.

Branding

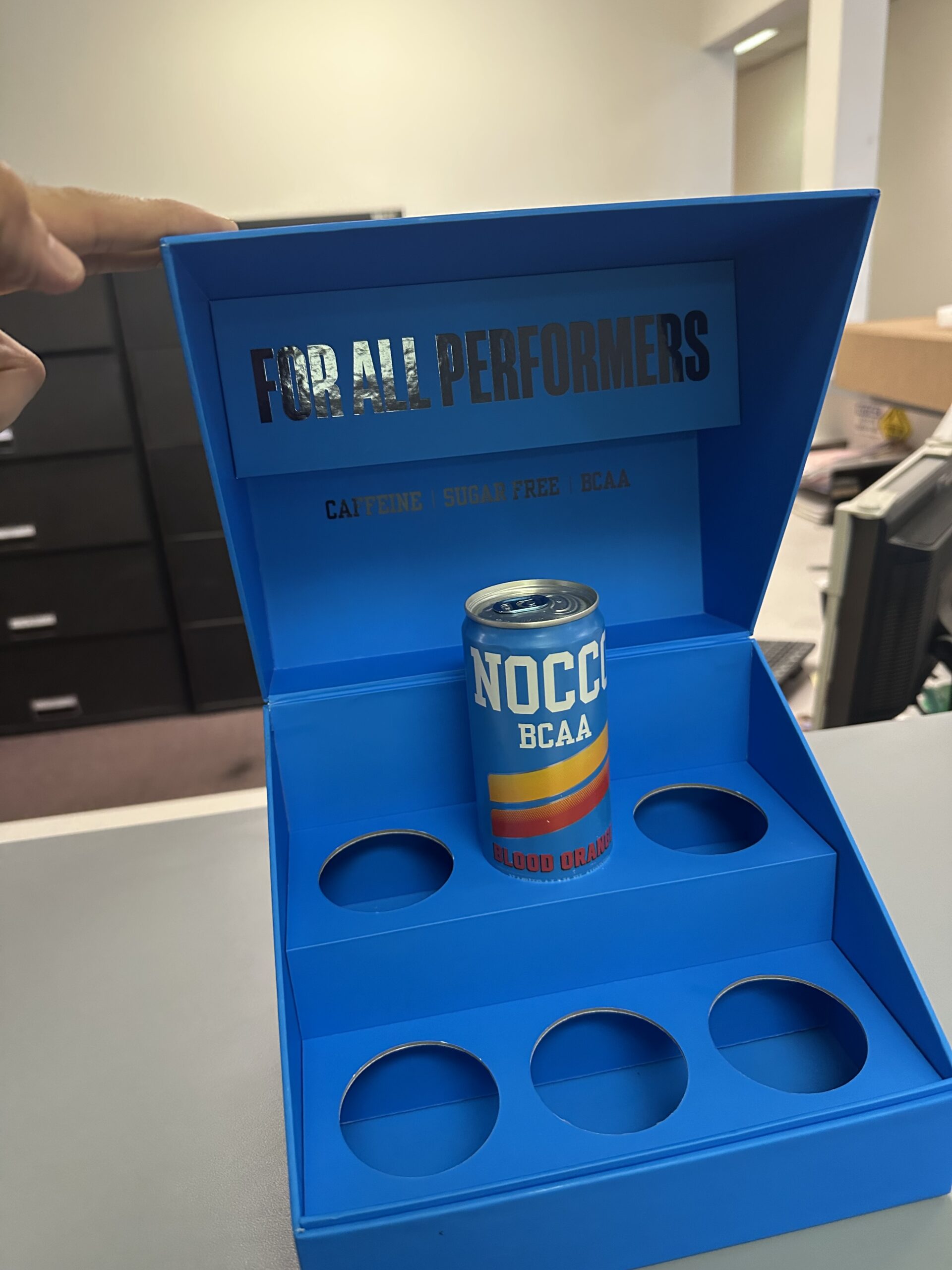

Food packaging is a valuable marketing tool for businesses, allowing them to promote their brand and differentiate their products from their competitors. Food packaging can include branding elements, such as logos, graphics, and product information, that help to build brand recognition and loyalty.

Convenience

Food packaging provides convenience for both businesses and consumers. Packaging can be designed to make it easy to store, transport, and dispense food products, while also providing a clean and convenient way to consume food on the go.

Cost Savings

Food packaging can help businesses to reduce costs by improving supply chain efficiency and reducing waste. For example, the use of barrier materials in food packaging can help to extend the shelf life of food products, reducing waste and the need for frequent restocking.

Compliance

Food packaging must comply with various regulations and standards, including those set by the FDA and other government agencies. Compliance with these regulations helps to ensure the safety of food products and protects the health of consumers.

These are just a few of the many reasons why businesses need food packaging. By using appropriate food packaging, businesses can improve the safety, quality, and marketability of their products, while also meeting the needs of their customers.

Common Food Packaging Materials

Food packaging materials come in a variety of forms, each with its own unique properties and benefits. Let’s take a closer look at some of the most common packaging materials used in the food industry:

Plastic (Polymers)

Plastic packaging is a popular choice due to its light weight, flexibility, and durability. Plastic packaging comes in a variety of forms, including bags, containers, trays, and more. Plastic packaging can be made from a variety of materials, including polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET). Each type of plastic has its own unique properties and benefits, making it suitable for different food packaging applications. For example, PE is commonly used for food bags due to its flexibility, while PET is used for beverage bottles due to its clarity and resistance to impact.

Corrugated

Corrugated packaging is made from corrugated cardboard and is commonly used for shipping and storing food products. It provides excellent protection against physical damage and is an eco-friendly alternative to other packaging materials. Corrugated packaging is also easily recyclable and biodegradable, making it a sustainable choice for food packaging.

Paperboard

Paperboard packaging is made from multiple layers of paper and is commonly used for packaging food products, such as cereal boxes and snack packs. Paperboard is lightweight, strong, and biodegradable, making it an environmentally friendly option. Some paperboard packaging also features a food-grade coating, making it suitable for direct food contact.

Glass

Glass packaging is commonly used for preserving food products, such as pickles, jams, and sauces. Glass is non-reactive, ensuring that the flavor and quality of food products remain intact. Glass is also recyclable and can be reused, making it a sustainable choice for food packaging.

Metal

Metal packaging is commonly used for preserving food products, such as canned goods. Metal packaging provides a barrier to light, air, and moisture, helping to preserve the freshness and quality of food products. Metal packaging can be made from a variety of materials, including tin, aluminum, and steel.

In addition to these common packaging materials, there are also various other materials used in the food packaging industry, including biodegradable and compostable packaging, such as bioplastic, and innovative materials, such as smart packaging, which includes features like temperature indicators and modified atmosphere packaging.

It’s important for businesses to carefully consider the materials used for food packaging to ensure that they meet both regulatory requirements and the needs of their customers. By choosing the right packaging materials and applications, businesses can provide their customers with high-quality, safe, and appealing food products.

Food Packaging Applications

Food packaging applications refer to the ways in which food products are packaged to protect and preserve them during storage and transportation. Here are some common packaging applications in the food industry:

Bags

Bags are a versatile and convenient form of packaging for food products, such as snacks, produce, and pet food. Bags can be made from a variety of materials, including plastic, paper, and biodegradable materials, and are available in a range of sizes and shapes.

Containers

Containers are a common form of packaging for food products, such as dairy products, baked goods, and prepared meals. Containers can be made from a variety of materials, including plastic, glass, and metal, and can be designed in a range of shapes and sizes to accommodate different food products.

Trays

Trays are a common form of packaging for food products, such as fruits, vegetables, and meats. Trays are often made from plastic or paperboard and can be designed to hold a specific product or to hold multiple products in a single package.

Bottles

Bottles are a common form of packaging for liquids, such as beverages, sauces, and condiments. Bottles can be made from a variety of materials, including glass, plastic, and metal, and are available in a range of sizes and shapes.

Cans

Cans are a common form of packaging for food products, such as soups, vegetables, and fruits. Cans are typically made from metal and provide a barrier to light, air, and moisture, helping to preserve the freshness and quality of food products.

Pouches

Pouches are a flexible form of packaging for food products, such as snack foods, pet food, and powdered products. Pouches can be made from a variety of materials, including plastic and paper, and are available in a range of sizes and shapes.

These are just a few of the many packaging applications used in the food industry. The specific packaging application used will depend on the needs of the product, including its size, shape, and intended use. Businesses must carefully consider the packaging application to ensure that it meets the needs of the product and provides adequate protection and preservation during storage and transportation.

Federal Drug Administration and Government Requirements

The Food and Drug Administration (FDA) and government agencies play a crucial role in regulating the food packaging industry, establishing standards and requirements to ensure the safety and quality of food products. Some of the key FDA and government requirements for food packaging include:

Material Safety

Food packaging materials must be safe for use in contact with food products. The FDA and government agencies evaluate food packaging materials for potential health risks and set standards for the use of food-contact materials, such as plastics and other polymers.

Label Information

Food packaging must include accurate and complete labeling information, including ingredient lists, nutritional information, and allergen warnings. This information helps consumers to make informed decisions about the food products they purchase and consume.

Packaging Design

Food packaging must be designed to protect food products from contamination and spoilage. The FDA and government agencies set standards for packaging design, including the use of barrier materials and the inclusion of features such as tamper-evident seals.

Microbial Control

Food packaging must be designed to control the growth of harmful microorganisms and prevent the spread of foodborne illnesses. The FDA and government agencies set standards for the control of pathogens in food packaging, including requirements for the use of antimicrobial treatments and the inclusion of features such as modified atmosphere packaging.

Recycling and Sustainability

The FDA and government agencies are increasingly focusing on the environmental impact of food packaging, including the use of recycled materials and the reduction of waste. Businesses must comply with recycling and sustainability requirements, such as using biodegradable packaging materials and reducing the amount of packaging waste generated.

These are just a few of the many FDA and government requirements for food packaging. Businesses must carefully consider these requirements when designing and manufacturing food packaging, to ensure that their products meet regulatory standards and provide adequate protection and preservation for food products.

Summary: Food Packaging Explained

In conclusion, food packaging is a vital component of the food industry, providing a wide range of benefits for both businesses and consumers. It helps to protect, preserve, and market food products, while also ensuring regulatory compliance and consumer safety.

With a wide range of packaging materials and products available, businesses must carefully consider their packaging needs and select the best options for their products. This requires a thorough understanding of the functional benefits of different packaging materials and the regulatory requirements set by the FDA and government agencies.

By investing in high-quality food packaging, businesses can improve the safety, quality, and marketability of their food products, helping to secure their place in the competitive food industry and meet the needs of consumers. Ultimately, food packaging is an essential element of the food supply chain, helping to ensure that food products reach consumers in the best possible condition.

If you are interested in food packaging, then contact Brown Packaging today to get started.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » The Importance of Food Packaging: Understanding Materials, Requirements, and Benefits

High Impact Polystyrene, commonly known as HIPS, is a versatile and widely used thermoplastic renowned for its unique blend of properties. This material is crucial

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

When it comes to protecting fragile or valuable items during shipping or storage, the choice of packaging material can make all the difference. Polyurethane foam