Home » The Drawbacks of DIY Packaging VS Partnering With A Professional

The Drawbacks of DIY Packaging VS Partnering With A Professional

In today’s digital age, online packaging companies offer the convenience of DIY packaging solutions. However, the allure of DIY packaging can mask significant challenges. In this comprehensive guide, we’ll explore the potential pitfalls of DIY packaging and emphasize the importance of partnering with a packaging professional.

The Allure of DIY Packaging

DIY packaging from online companies has gained popularity for several reasons:

- Convenience: Ordering packaging materials online is convenient and can be done at any time, from anywhere.

- Cost Control: DIY packaging allows businesses to have control over their packaging costs by selecting materials and quantities according to their budget.

- Customization: Online platforms often offer customization options, allowing businesses to add branding and tailor packaging to their needs.

- Speed: Some online packaging services promise quick turnaround times, appealing to businesses with tight schedules.

However, the allure of DIY packaging can often mask some significant challenges:

Limited Expertise: Designing effective packaging requires expertise in materials, structural engineering, and graphic design. Many DIY users lack the knowledge to create packaging that provides optimal protection and branding impact.

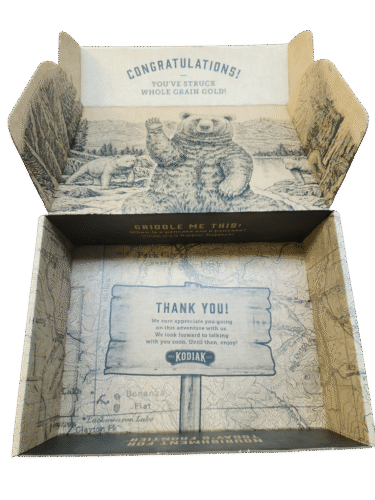

Branding and Design Limitations: While online platforms offer customization options, they may have limitations in terms of design flexibility, color accuracy, and finishing options. Achieving a unique and branded look can be challenging.

Quality Control: DIY packaging often lacks quality control measures. Users may receive subpar materials or printing results, leading to unsatisfactory outcomes and potential product damage during transit.

Inefficient Prototyping: Testing and prototyping packaging designs can be challenging with online DIY services. You may have to place multiple orders to iterate and improve your packaging, which can be time-consuming and costly.

Material Selection: Selecting the right packaging materials is critical for product safety and presentation. DIY users may struggle to identify the most suitable materials for their specific products.

Limited Support: Online packaging companies may provide limited customer support, making it challenging to resolve issues or seek advice during the design and ordering process.

Hidden Costs: While DIY packaging appears cost-effective at first glance, the total cost of multiple revisions, returns, and damaged products can add up quickly.

The Importance of a Packaging Professional

Partnering with a packaging professional offers several advantages:

- Expertise: Packaging professionals can guide you in selecting the right materials, designs, and finishes to meet your unique needs.

- Quality Assurance: Packaging professionals prioritize quality control, ensuring that your packaging materials and designs meet high standards.

- Customization: They offer more extensive customization options, allowing you to create packaging that truly reflects your brand identity.

- Prototyping and Testing: Packaging professionals facilitate prototyping and testing, helping you refine your packaging design for optimal results.

- Problem Resolution: If issues arise, a dedicated team is available to resolve them promptly, saving you time and frustration.

- Efficiency: Packaging professionals streamline the ordering process, reducing the risk of hidden costs and delays.

Conclusion

While the convenience of DIY packaging from online companies may seem enticing, it often falls short in delivering the desired results. The pitfalls of limited expertise, design constraints, and quality issues can have a significant impact on your brand’s image and product protection. Partnering with a packaging professional empowers you with the expertise, support, and quality assurance necessary to create packaging solutions that truly meet your needs. When it comes to packaging, it’s worth investing in a partner who prioritizes your success and ensures that your packaging aligns with your brand’s identity and customer expectations.

If you are interested in professional packaging solutions, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » The Drawbacks of DIY Packaging VS Partnering With A Professional