Home » Testing Packaging for Peak Season Loads

Testing Packaging for Peak Season Loads

Holiday e-commerce volumes push packaging to its limits. Trailers are overfilled, handling is rushed, and parcels endure more drops and vibration than usual. Without proper testing, even well-designed packaging may fail under peak season conditions, leading to damage, costly returns, and dissatisfied customers.

Why Peak Season Testing Is Critical

- Higher stacking pressures: Boxes face extreme compression in full trailers.

- More frequent handling: Extra scans and transfers increase drop risk.

- Transit vibrations: Long-haul shipping amplifies mechanical stress.

- Environmental extremes: Moisture and temperature swings impact materials.

Peak conditions require packaging that goes beyond normal performance thresholds.

Types of Packaging Tests for Peak Season

- Compression testing: Measures stacking strength of corrugated boxes.

- Drop testing: Simulates impacts during warehouse and carrier handling.

- Vibration testing: Evaluates product protection in long-haul transit.

- Edge crush test (ECT): Determines box wall strength against vertical pressure.

- Moisture testing: Assesses packaging durability in variable climates.

Balancing Cost and Testing Rigor

Not every SKU requires the same testing intensity. Packaging buyers should prioritize:

- High-value or fragile products.

- Items with past return/damage history.

- Heavy SKUs prone to crushing or shifting.

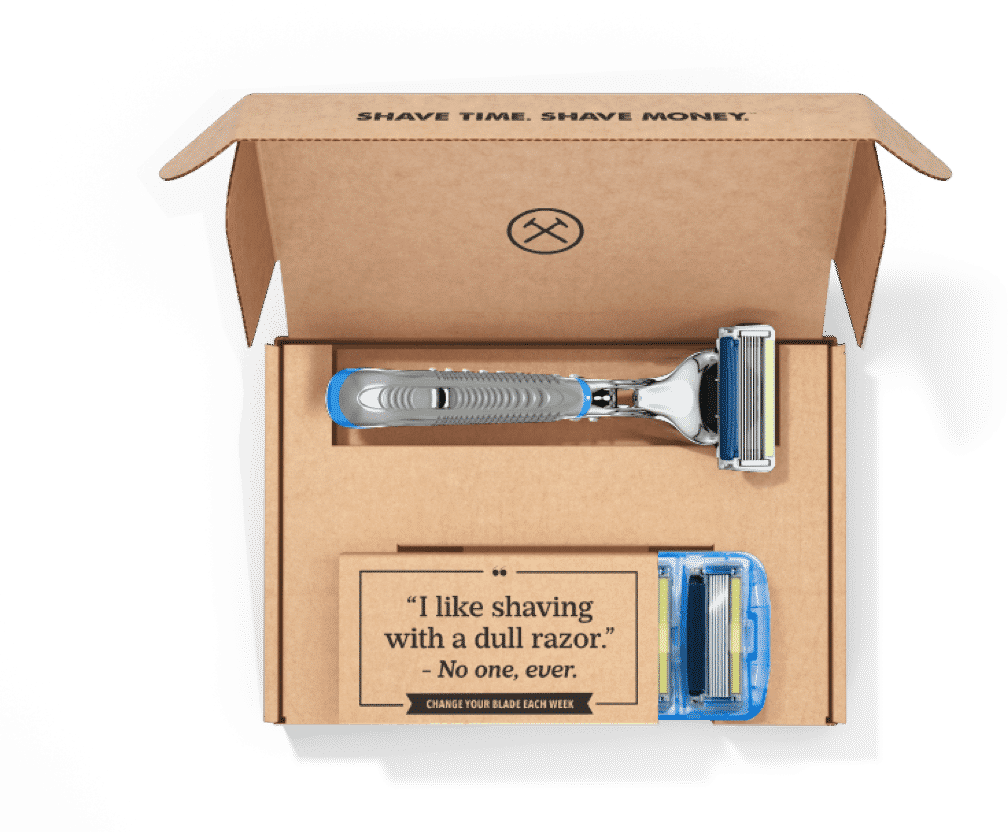

- Subscription or seasonal kits with multiple components.

Testing can be scaled to focus on products where risk is highest.

Holiday Packaging and Supply Chain Alignment

Testing should be tied directly to peak-season logistics strategies. Packaging must:

- Meet retailer compliance standards.

- Withstand real-world shipping simulations.

- Be validated before production ramps for holiday campaigns.

Holiday Packaging Solutions with Brown Packaging

Brown Packaging helps brands test and validate packaging for peak season. Using industry-standard methods, we ensure designs hold up against compression, vibration, and environmental stress during high-volume shipping. Contact us to safeguard your holiday packaging.

References

ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.

International Safe Transit Association (ISTA). (2022). ISTA Test Procedures for Packaged Products in Transit.

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Testing Packaging for Peak Season Loads