Home » Strategies to Protect Packaging Against Tampering and Theft

Strategies to Protect Packaging Against Tampering and Theft

Tampering and theft are significant concerns for manufacturers and consumers alike. Tampered products can pose health and safety risks, while theft results in financial losses. To ensure the integrity of your products and packaging, as well as protect against theft, it’s essential to implement effective tamper-resistant and theft-deterrent measures. In this blog, we’ll explore various strategies and best practices to help you protect your packaging against tampering and theft effectively.

Understanding the Threat

Before we delve into protective measures, it’s crucial to understand the potential risks associated with tampering and theft:

- Safety Hazard: Tampered products can become contaminated or altered, posing health and safety risks to consumers.

- Loss of Consumer Trust: Incidents of tampering can lead to a loss of consumer trust in your brand and result in reputational damage.

- Regulatory Violations: Tampering incidents may lead to legal and regulatory issues, including recalls and fines.

- Financial Loss: Theft of products during transit or from store shelves can result in significant financial losses for manufacturers and retailers.

Protective Measures

To safeguard your packaging against tampering and theft, consider implementing the following protective measures:

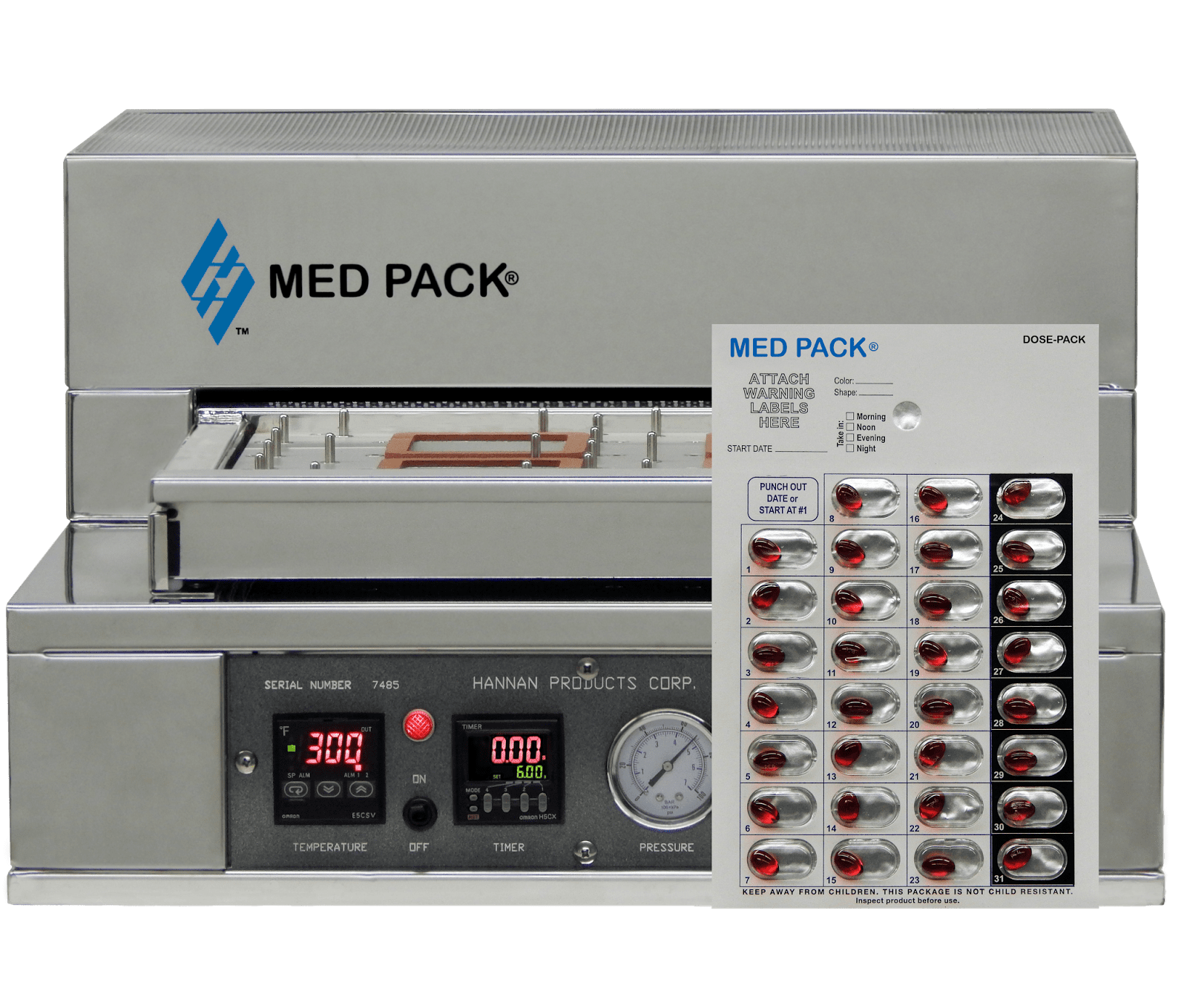

Tamper-Evident Packaging:

Incorporate tamper-evident features into your packaging design. These features provide visible evidence of tampering, making it evident if a package has been compromised. Common tamper-evident features include:

- Shrink Bands: Applied around the cap or lid, shrink bands break or distort when tampered with.

- Tear Strips: These strips are designed to be broken for package access and leave visible evidence when torn.

- Breakable Seals: Seals that must be broken to open the package.

- Frangible Components: Components that break or shatter when manipulated.

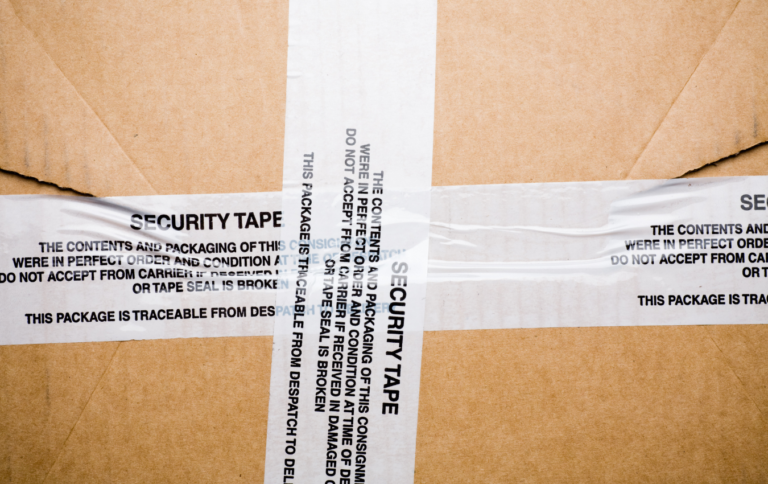

Security Labels and Stickers:

Apply security labels or stickers to packaging surfaces. These labels are designed to leave a visible mark or message when removed, indicating tampering. Some labels even feature holograms or unique identifiers for added security.

Serialization and Track-and-Trace Systems:

Implement serialization and track-and-trace systems to monitor and authenticate product movement through the supply chain. These systems help identify anomalies and potential tampering incidents and can aid in tracking stolen products.

Employee Training:

Train your staff to recognize signs of tampering and follow proper security procedures. Encourage them to report any suspicious activities or findings promptly.

Regulatory Compliance:

Adhere to industry and regulatory standards for tamper-evident packaging. Compliance ensures that your products meet safety and security requirements.

Theft-Deterrent Packaging:

Design packaging to deter theft. Utilize features like clear plastic clamshells, locking mechanisms, or security tags that activate alarms when removed.

Security Cameras and Alarms:

Implement security measures in storage facilities and retail spaces, including security cameras and alarm systems. These systems can deter theft and provide evidence in case of incidents.

Package Design Considerations:

Design packaging with tamper resistance and theft deterrence in mind. Use materials that are difficult to tamper with or require specialized tools for opening. Consider tamper-resistant closures and packaging that can’t be easily concealed or stolen.

Collaboration with Retailers:

Work closely with retailers to implement anti-theft measures. Retailers can use anti-shoplifting devices, secure shelving, and trained staff to deter theft.

Regular Inspections and Testing:

Maintain a proactive approach to protection by regularly inspecting products for tampering and theft. Conduct theft tests to identify vulnerabilities and make necessary adjustments.

Vigilance and Continuous Improvement

Protecting your packaging against tampering and theft is an ongoing effort. Continuously assess your packaging solutions and gather feedback from consumers, retailers, and regulatory agencies. Stay vigilant and proactive in addressing any potential vulnerabilities or emerging threats.

By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of tampering and theft incidents, enhance the safety and trustworthiness of your products, and safeguard your financial interests.

If you are interested in protection against tampering and theft for your packaging, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Strategies to Protect Packaging Against Tampering and Theft