Home » Strategies to Protect Packaging Against Physical Damage

Strategies to Protect Packaging Against Physical Damage

Packaging is the first line of defense for your products, shielding them from the hazards they may encounter during storage, handling, and transportation. One of the most critical aspects of packaging is safeguarding it against physical damage. In this blog, we’ll delve into various strategies and best practices to help you protect your packaging from physical harm, ensuring that your products remain safe and intact.

Understanding the Risks

Before delving into protective measures, it’s crucial to understand the potential sources of physical damage that your packaging might face:

- Impact during Handling: Packages can be dropped, bumped, or mishandled during various stages of transportation and storage.

- Compression: Stacking heavy items or applying excessive pressure can lead to package deformation or crushing.

- Vibration: Prolonged exposure to vibrations, especially in long-distance shipping, can weaken packaging materials and affect their integrity.

- Sharp Objects: Sharp objects in the vicinity of packages can puncture or tear the packaging material.

Protective Measures

To safeguard your packaging from physical damage, consider the following protective measures:

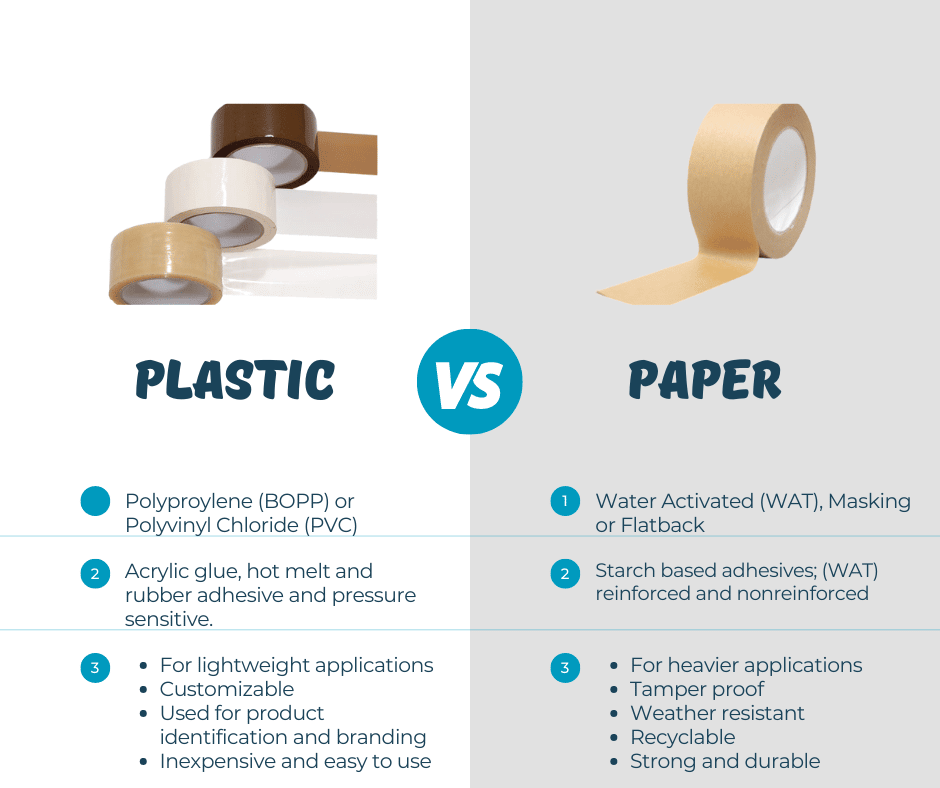

Material Selection:

Choosing the right packaging material is paramount. Select materials known for their durability, strength, and resistance to physical damage.

Reinforced Corners and Edges:

Weak points in packaging are often the corners and edges. Reinforce these vulnerable areas with additional layers of material or protective corner guards to absorb impact and prevent crushing.

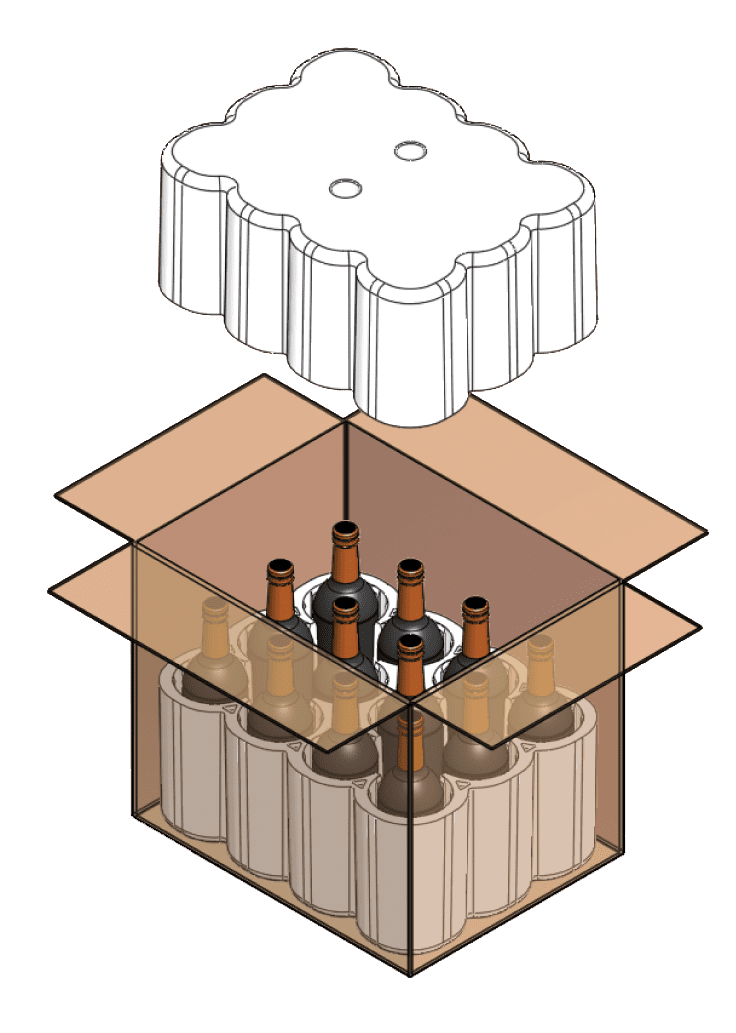

Cushioning and Padding:

Using cushioning materials like bubble wrap, foam inserts, or air pillows can provide a protective buffer against shocks and vibrations. Ensure that products are snugly cushioned inside the packaging.

Stacking Strength:

If stacking is a concern, design packaging with enhanced stacking strength. Reinforce the packaging structure to distribute weight evenly and minimize the risk of crushing.

Inner Packaging Layers:

For particularly fragile or sensitive items, consider adding inner packaging layers. These can include protective pouches, sleeves, or dividers to prevent product-to-product contact and potential damage.

Impact Indicators:

Use impact indicators or shock labels on packages. These devices can detect and record impacts during transportation, allowing you to identify and address any potential issues promptly.

Testing and Quality Control:

Implement rigorous testing procedures to ensure the packaging can withstand expected impacts and stresses. Conduct drop tests, compression tests, and vibration tests to assess package durability.

Customized Packaging Design:

Tailor packaging designs to fit the specific requirements of your products. Avoid using oversized boxes, as this can lead to excessive movement and damage.

Handling and Storage Guidelines:

Provide clear instructions for handling and stacking packages. Train employees and partners involved in the packaging and transportation process to follow these guidelines diligently.

Regular Evaluation and Improvement

The protection of your packaging from physical damage is an ongoing process. Continuously assess your packaging solutions and gather feedback from transportation partners to identify any weaknesses or areas for improvement. Make necessary adjustments to enhance packaging resilience and ensure that your products arrive at their destination in optimal condition.

By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of physical damage to your products and enhance their overall quality and safety.

If you are interested in safe and proper packaging, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Strategies to Protect Packaging Against Physical Damage