Home » Strategies to Protect Packaging against Oxygen and Air Exposure

Strategies to Protect Packaging against Oxygen and Air Exposure

Oxygen and air exposure can adversely affect the quality, shelf life, and safety of your products. To ensure the integrity of your products and packaging, it’s essential to implement effective measures to protect against oxygen and air infiltration. In this blog, we will explore various strategies and best practices to help you safeguard your packaging against these environmental factors effectively.

Understanding the Threat

Before we delve into protective measures, it’s crucial to understand the potential risks associated with oxygen and air exposure:

- Oxidation: Exposure to oxygen can lead to oxidation, which can cause changes in color, flavor, and texture of food products, as well as the degradation of certain chemicals and pharmaceuticals.

- Spoilage: Oxygen can promote the growth of spoilage organisms and pathogens in perishable products, leading to product spoilage and safety concerns.

- Product Degradation: In some cases, oxygen exposure can trigger chemical reactions in products, causing them to deteriorate or lose efficacy.

Protective Measures

To safeguard your packaging against oxygen and air exposure, consider implementing the following protective measures:

Oxygen Barrier Packaging Materials:

Choose packaging materials with oxygen barrier properties. These materials prevent oxygen from permeating the package and coming into contact with the product. Common oxygen barrier materials include metallized films, aluminum foil, and certain plastics.

Vacuum-Sealed Packaging:

Utilize vacuum-sealing methods to remove air from the package before sealing it. Vacuum-sealed packaging creates an airtight environment that minimizes oxygen exposure.

Nitrogen Flushing:

Implement nitrogen flushing or gas flushing during the packaging process. This involves replacing the air inside the package with nitrogen or an inert gas to displace oxygen.

Modified Atmosphere Packaging (MAP):

Consider modified atmosphere packaging, where the atmosphere inside the package is modified to contain lower oxygen levels. This is common in the packaging of fresh produce and meats.

Seal Integrity:

Ensure that packaging seals are strong and airtight. Regular quality control checks should verify that no gaps or defects exist in the sealing process, preventing oxygen infiltration.

Desiccants and Oxygen Absorbers:

Include desiccants or oxygen absorbers inside the packaging. Desiccants remove moisture, which can contribute to oxidation, while oxygen absorbers remove oxygen, extending shelf life.

Quality Control Checks:

Conduct quality control checks to verify the effectiveness of oxygen protection measures. Use oxygen permeability testing to assess packaging materials.

Barrier Films and Coatings:

Apply oxygen barrier films or coatings to packaging materials. These films and coatings create an additional layer of protection against oxygen infiltration.

Regulatory Compliance:

Adhere to industry-specific and regulatory standards for products that require protection against oxygen exposure. Compliance ensures that your products meet safety and quality requirements.

Vigilance and Continuous Improvement

Protecting your packaging against oxygen and air exposure is an ongoing effort. Continuously assess your packaging solutions and gather feedback from consumers, retailers, and quality control personnel to identify any weaknesses or areas for improvement. Stay vigilant and proactive in addressing potential risks related to oxygen and air exposure.

By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of oxygen-related damage to your products, enhance their overall quality and safety, and ensure that your packaging maintains the highest standards of protection against these environmental factors.

If you are interested in protection against oxygen and air exposure for your packaging, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Strategies to Protect Packaging against Oxygen and Air Exposure

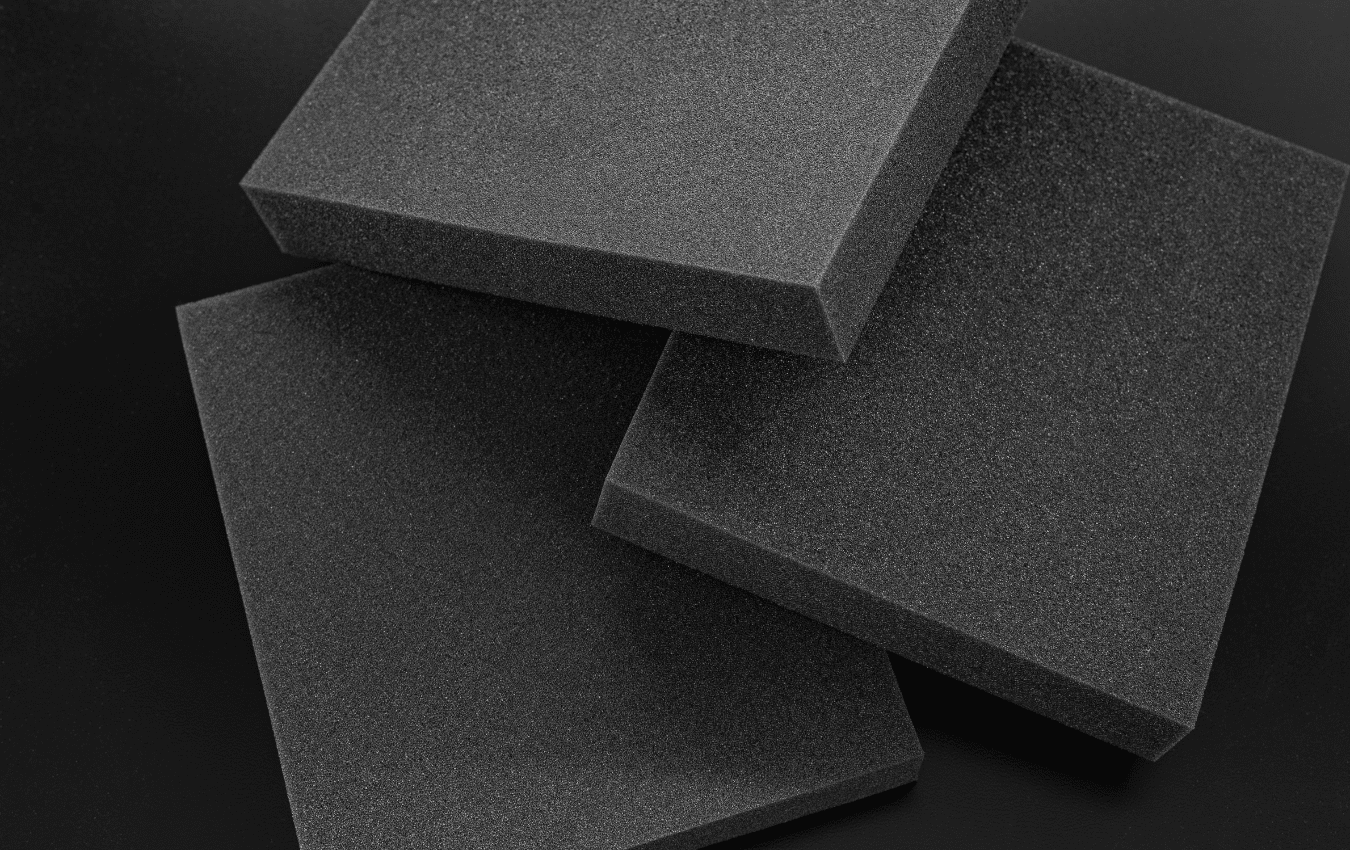

Packaging is a crucial aspect of any business that deals with physical products. Custom die-cut foam is a popular packaging material that offers excellent cushioning

In the world of packaging and shipping, one of the most critical concerns is breakage – the damage that occurs to products during transit. This

Polyethylene terephthalate, commonly abbreviated, stands out in the packaging industry for its versatility and environmental friendliness. Recognized as the most widely recycled plastic worldwide, this