Home » RSC Boxes vs. RETT Corrugated Mailers

RSC Boxes vs. RETT Corrugated Mailers

When choosing corrugated packaging, box style directly impacts cost, strength, speed of packing, and customer experience. Two of the most common options are the Regular Slotted Container (RSC) and the Roll-End Tuck-Top (RETT) mailer. While both protect products well, their design differences make each suited for very different needs.

Regular Slotted Container (RSC)

Design & Features

- Flaps of equal length meet in the center.

- Requires tape, glue, or staples for closure.

- Minimal board waste, highly efficient to manufacture.

Advantages

- Strong and Stackable: Excellent compression strength for palletized loads.

- Cost-Efficient: Standardized design lowers production cost.

- Versatile: Common in nearly every industry.

Limitations

- Slower Assembly: Tape or glue required for every box.

- Basic Presentation: Not designed for branded unboxing experiences.

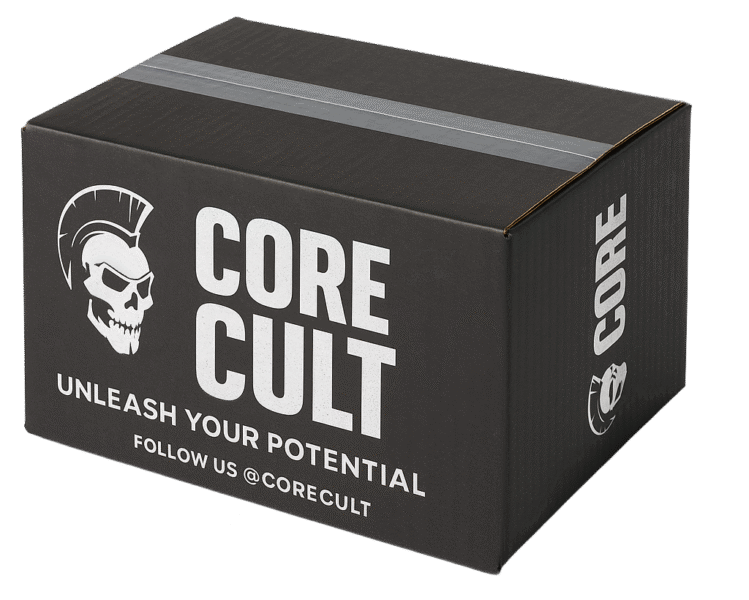

Roll-End Tuck-Top (RETT) Mailer

Design & Features

- Single-piece die-cut design.

- Built-in dust flaps protect contents from debris.

- Cherry locks (small locking tabs) keep the lid secure without tape.

Advantages

- Fast Assembly: Self-locking design saves time and eliminates tape.

- Premium Look: Ideal for branded unboxing and e-commerce.

- Better Closure: Dust flaps improve integrity; cherry locks prevent accidental opening.

Limitations

- Higher Cost: Requires custom tooling and more board.

- Lower Stacking Strength: Not as durable for bulk palletized shipping.

- Less Flexible for Large Sizes: Best suited to small-to-medium e-commerce parcels.

RSC vs. RETT: Side-by-Side Comparison

Feature | RSC Box | RETT Mailer |

Closure Method | Tape, glue, or staples | Dust flaps + cherry locks (self-locking) |

Assembly Speed | Slower | Faster |

Stacking Strength | High (pallet loads) | Moderate |

Cost | Lower | Higher |

Branding & Unboxing | Basic | Premium |

Best For | Bulk shipping, warehousing, palletization | E-commerce, subscription boxes, retail-ready packaging |

Regular Slotted Container (RSC)

Roll End Tuck Top (RETT) with cherry lock and dust flaps

Buyer Takeaways

- Choose an RSC if you need maximum stacking strength and shipping efficiency. Perfect for palletized loads, warehouses, and industrial distribution.

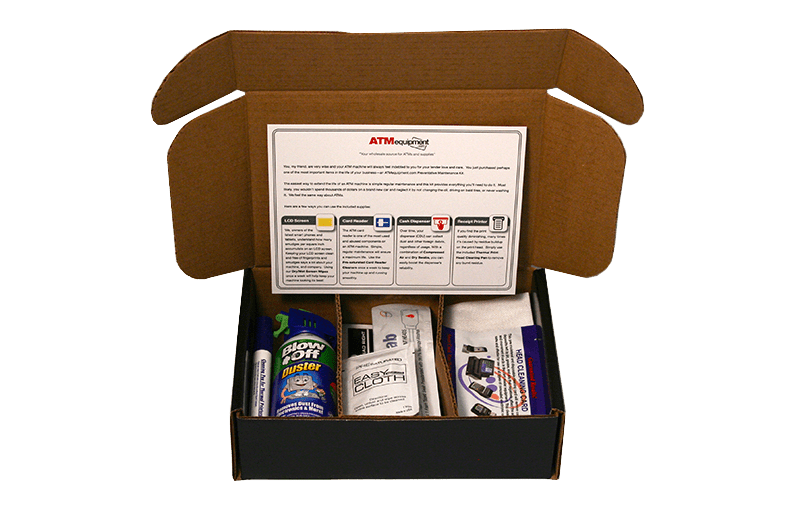

- Choose a RETT mailer if your focus is branding, presentation, and fast assembly. Ideal for e-commerce, D2C shipments, and subscription boxes.

- Dust flaps and cherry locks make RETT mailers especially well-suited to online retail, where presentation and secure delivery both matter.

References

- Fibre Box Association. (2023). Corrugated Box Styles and Design Guide. https://www.fibrebox.org

- Association of Independent Corrugated Converters (AICC). (2024). Corrugated Packaging Fundamentals. https://www.aiccbox.org

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » RSC Boxes vs. RETT Corrugated Mailers