Home » RSC Boxes in Freight Optimization

RSC Boxes in Freight Optimization

RSC boxes dominate shipping because they combine strength with efficiency. But beyond protection, their dimensions and stacking performance directly influence freight cost, pallet utilization, and warehouse efficiency. Choosing the right RSC design can reduce supply chain costs by double digits.

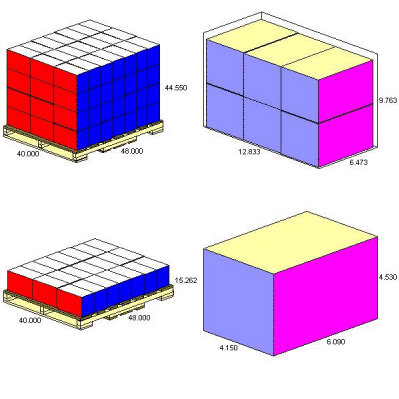

Pallet Utilization

- Box Size and Fit

An RSC that doesn’t optimize pallet footprint wastes space. Even a 1–2 inch mismatch can reduce units per pallet by 5–10%. - Standard Pallet Sizes

In North America, most pallets are 48” x 40”. Designing RSC dimensions to fit evenly across this footprint maximizes stacking stability. - Load Stability

Uniform RSC dimensions improve compression strength across the load, reducing toppling and damage in transit.

Dimensional Weight (DIM) Charges

- Carrier Pricing Models

Carriers like UPS and FedEx charge based on dimensional weight, not just actual weight. Oversized RSC boxes can inflate costs significantly. - Right-Sizing

Selecting an RSC that closely matches product volume reduces cube size, cutting freight charges. - Impact on E-Commerce

For direct-to-consumer shipments, oversize RSC boxes can double shipping cost while raising material expense.

Stacking and Compression

- Box Compression Test (BCT)

Determines how much weight an RSC can withstand in a stacked load. - Real-World Factor

Moisture and long-term storage reduce compression strength. Oversizing boxes to “play it safe” only increases freight cost. Instead, balance board grade with actual load needs.

Warehouse Efficiency

- Knock-Down Storage

RSC boxes ship and store flat, reducing warehouse footprint compared to assembled specialty mailers. - Automation

Consistent RSC dimensions reduce jams in case erectors and palletizers, improving throughput.

Buyer Takeaway

- Use RSC dimensions that align with pallet footprints to maximize utilization.

- Avoid oversized boxes — dimensional weight charges add hidden costs.

- Match board grade and box size to actual load requirements instead of over-specifying.

- Optimized RSC design isn’t just packaging — it’s a supply chain cost-control tool.

References

- Fibre Box Association. (2023). Palletization and Shipping Standards. https://www.fibrebox.org

- International Safe Transit Association (ISTA). (2023). Distribution Testing Protocols. https://ista.org

- Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » RSC Boxes in Freight Optimization