Home » Revolutionizing Protection: The Latest Technological Innovations in Protective Packaging

Revolutionizing Protection: The Latest Technological Innovations in Protective Packaging

In today’s fast-paced world, protecting fragile and valuable items during transportation is of utmost importance. Whether it’s delicate electronics, intricate machinery, or even perishable goods, reliable and innovative protective packaging solutions are essential to ensure products reach their destination unharmed.

Over the years, advancements in technology have revolutionized the field of protective packaging, offering improved safety, efficiency, and sustainability. In this blog, we will delve into some of the most exciting technology innovations in protective packaging and explore their potential to transform the industry.

Smart Packaging

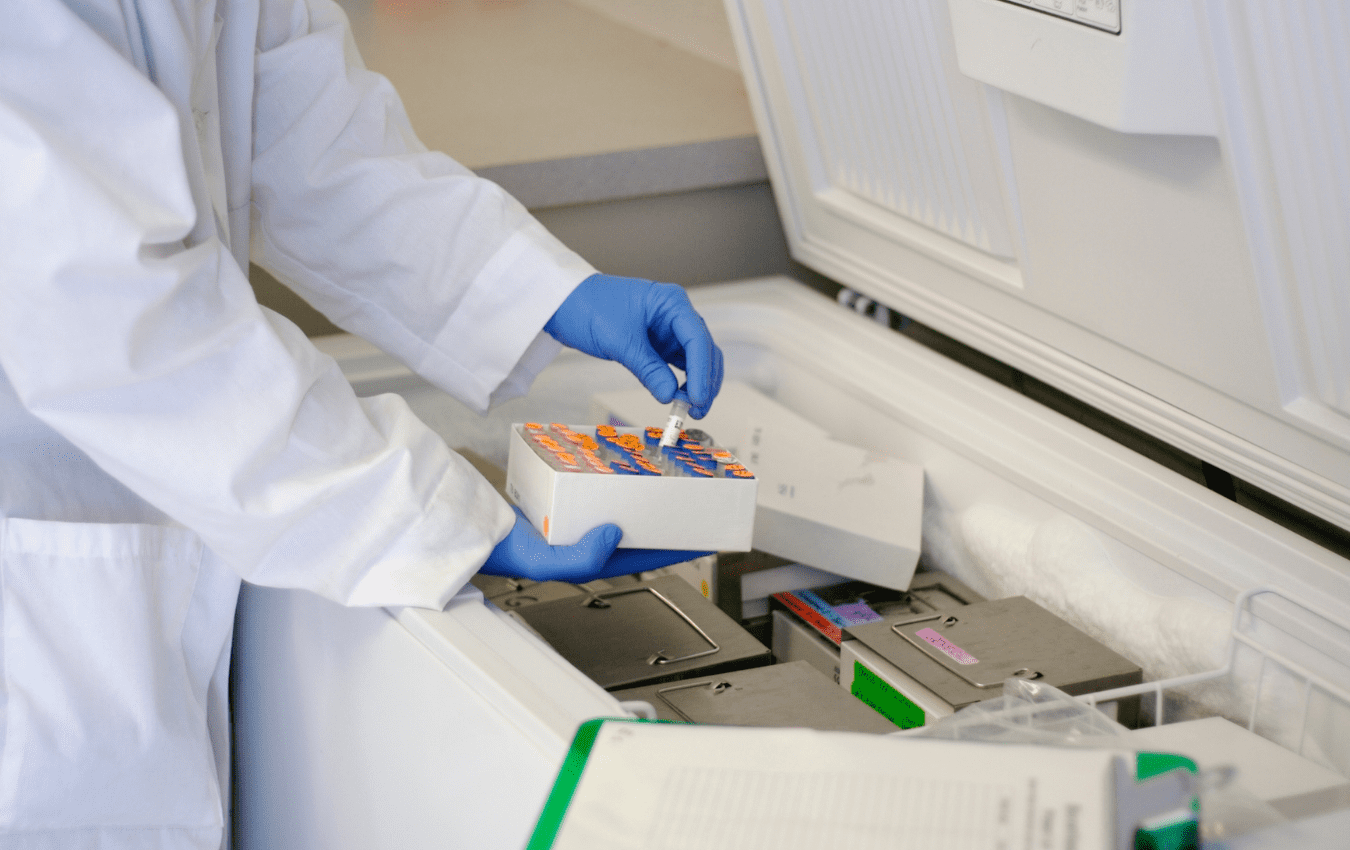

The integration of smart technologies into packaging has brought about a paradigm shift in protective packaging. Sensors and embedded devices now enable real-time monitoring of various environmental conditions, including temperature, humidity, pressure, and even shock. This data helps companies identify potential risks and take proactive measures to prevent damage.

For instance, pharmaceutical companies can monitor temperature-sensitive medications to ensure they remain within the required temperature range during transit. Furthermore, smart packaging can also provide end-to-end visibility, allowing customers and businesses to track their packages in real-time, enhancing security and peace of mind.

Active Packaging

Active packaging involves incorporating active substances or systems within packaging materials to extend the shelf life of perishable products. For instance, oxygen absorbers and moisture control packets help maintain the freshness of food items, reducing spoilage and waste. Similarly, antimicrobial packaging inhibits the growth of bacteria, ensuring the safety and longevity of medical supplies and food products. By actively interacting with the product or its environment, these packaging solutions actively contribute to preserving the quality and integrity of goods during storage and transportation.

Eco-friendly Materials

Sustainability is a key focus in the packaging industry, and protective packaging is no exception. Innovations in eco-friendly materials have paved the way for greener packaging solutions. Biodegradable and compostable packaging materials derived from renewable resources, such as plant-based plastics are gaining popularity.

These materials offer comparable protective properties while significantly reducing the environmental impact associated with traditional packaging. Moreover, advancements in recycling technologies allow for the efficient reprocessing of packaging materials, promoting a circular economy.

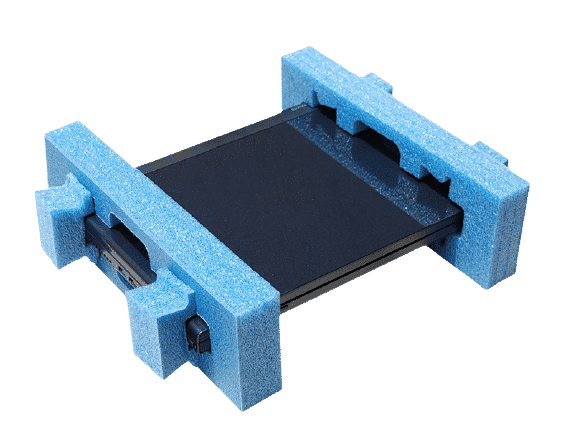

Shock-Resistant Packaging

One of the primary challenges in protective packaging is mitigating the impact of shocks and vibrations during transportation. Recent technological advancements have led to the development of shock-resistant packaging materials with enhanced cushioning properties. For instance, advanced foam materials, such as polyethylene (PE or EPE) foams, polyurethane (PU) foams, and cross-linked foams, offer excellent shock absorption capabilities.

Final Thoughts: Protective Packaging Technology Innovations

Technology innovations in protective packaging have revolutionized the way we safeguard valuable and fragile items during transportation. From smart packaging with real-time monitoring capabilities to active packaging that extends the shelf life of perishable goods, these advancements have significantly improved safety and efficiency.

Additionally, the adoption of eco-friendly materials and the development of shock-resistant packaging have contributed to reducing environmental impact and mitigating damage caused by transportation hazards. As technology continues to evolve, we can expect further advancements in protective packaging, ensuring the safe and secure delivery of products in the future.

If you are interested in protective packaging, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Home » Revolutionizing Protection: The Latest Technological Innovations in Protective Packaging

Packaging foam is essential for protecting products against shocks, vibrations, and other potential damages during transportation and storage. Understanding the different types of packaging foam

There’s a common saying in the marketing world: “It’s not what you sell that matters as much as how you sell it.” While the quality

Packaging is a crucial aspect of any business that deals with physical products. Custom die-cut foam is a popular packaging material that offers excellent cushioning