Home » Pallet Optimization Explained: Packaging, Tips and Benefits

Pallet Optimization Explained: Packaging, Tips and Benefits

Pallet optimization is the process of maximizing efficiency in space utilization and handling while minimizing freight costs. It requires strategic use of surface area, stacking height, and protective measures such as corner boards, straps, and stretch film. Effective pallet optimization not only reduces costs but also improves safety, prevents product loss, and ensures compliance with retailer requirements.

Why Pallet Optimization Matters

Logistics Efficiency: Optimized pallets reduce wasted space in trucks, warehouses, and distribution centers.

Cost Reduction: Better space utilization lowers freight expenses by reducing pallet count and dimensional charges.

Retail Compliance: Many retailers enforce pallet standards to streamline storage and handling.

Safety: Stable pallets minimize risk of shifting loads and workplace accidents.

9 Tips for Pallet Optimization

Optimize Packaging Design

Uniform, properly sized packaging stacks securely. Avoid oversized cartons, sharp edges, or unnecessary void space that weakens stability and wastes pallet capacity.

Select the Right Packaging Material

Corrugated strength impacts pallet load stability. Damaged cartons compromise entire stacks. Choose materials that withstand compression, vibration, and environmental stress.

Consider Supply Chain Conditions

Heat, humidity, cold, and shock affect packaging integrity. Use appropriate protective materials (foam, bubble wrap, anti-static additives) and pallet reinforcements.

Place Heavier Items at the Bottom

A stable foundation prevents crushing of lighter cartons and reduces shifting risk during transit.

Stack to the Edge, Not Beyond

Overhanging cartons weaken load stability and may incur additional carrier fees. Align cartons flush with pallet edges.

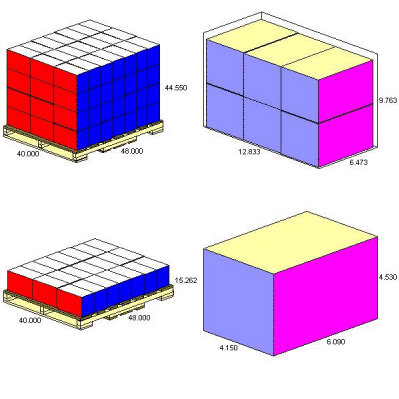

Use Pallet Optimization Software

Tools like CAPE, StackBuilder, and Best Pallet provide load simulations to maximize cube utilization and safety.

Keep Edges Straight and Uniform

Square, even loads distribute weight evenly. Avoid pyramid-style stacking, which destabilizes pallets and reduces efficiency.

Apply the Correct Stretch Film

Film strength and elasticity should match load weight and configuration. Specialty films with additives can improve performance in challenging conditions.

Add Straps if Needed

Polypropylene, steel, polyester, or cord straps provide additional stability. Combining strapping with corner boards and slip sheets further improves safety.

Benefits of Pallet Optimization

Improved Safety: Stable pallets reduce workplace injuries and accidents.

Reduced Shipping Costs: Maximizing cartons per pallet lowers freight and fuel expenses.

Faster Handling: Uniform stacks improve speed and accuracy during loading and unloading.

Product Protection: Properly secured pallets prevent carton damage and inventory loss.

Better Space Utilization: Optimized loads maximize warehouse and trailer capacity.

Buyer Takeaway

Pallet optimization is more than stacking boxes neatly—it’s a supply chain strategy. By optimizing packaging design, material strength, and pallet configurations, businesses can reduce costs, improve safety, and meet retailer requirements. The investment in software, stretch film, or strapping often pays for itself in fewer freight charges and reduced product damage.

References

International Safe Transit Association (ISTA). (2023). Distribution Testing Standards. Retrieved from https://ista.org

Fibre Box Association. (2023). Palletization and Corrugated Packaging. Retrieved from https://www.fibrebox.org

Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Home » Pallet Optimization Explained: Packaging, Tips and Benefits

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient