Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

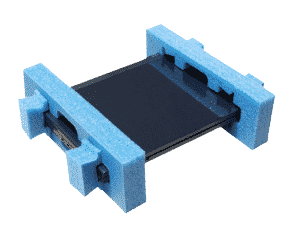

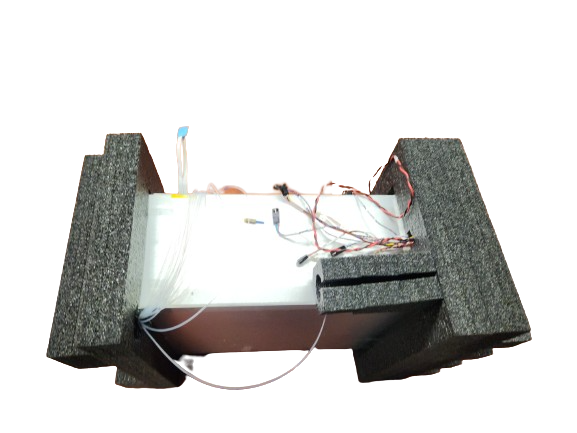

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

Packaging design is a crucial aspect of any product’s marketing strategy. It serves as a visual ambassador for your brand and plays a pivotal role in attracting and engaging your target audience. In this blog post, we will explore how marketing teams can build an effective packaging design tailored to their audience. Understand Your Audience The first step in designing packaging that resonates with your audience is to thoroughly understand who your audience is. This involves: Conducting market research: Gather data on your target demographic, including their preferences, buying behaviors, and lifestyle. Creating buyer personas: Develop detailed profiles of your ideal customers, considering factors like age, gender, income, interests, and values. Analyzing competitors: Study how your competitors are packaging similar products and identify gaps or opportunities to stand out. Define Your Brand Identity Before delving into design, ensure your team has a strong grasp of your brand identity. Your packaging should consistently reflect your brand’s values, mission, and personality. This includes: Brand messaging: Define the key messages you want to convey through your packaging. Is your brand known for sustainability, luxury, or affordability? Color palette and typography: Establish a consistent color scheme and font style that align with your brand’s personality. These elements should be recognizable and evoke specific emotions. Logo placement: Decide where your logo will be prominently featured on the packaging. This ensures brand recognition and reinforces your identity. Focus on Functionality Effective packaging design isn’t just about aesthetics; it also needs to be practical and functional. Consider the following aspects: Product protection: Ensure your packaging provides adequate protection for the product. Fragile items may require cushioning, while food products may need tamper-evident seals. Ease of use: Make it easy for customers to open, access, and use the product. User-friendly packaging can enhance the overall customer experience. Storage and shelf space: Design packaging that is stackable and doesn’t take up excessive shelf space, as this can impact retailers’ willingness to stock your product. Incorporate Storytelling Packaging is an opportunity to tell a story and connect with your audience on a deeper level. You can achieve this through: Visual storytelling: Use imagery and graphics to convey your brand’s story, values, and product benefits. Visual elements should be consistent with your brand’s narrative. Content writing: Craft compelling and concise copy that engages consumers. Highlight key features, benefits, and unique selling points. QR codes and augmented reality: Incorporate technology to provide customers with an interactive experience, such as access to additional information or videos related to your product. Sustainability Matters Today’s consumers are increasingly eco-conscious, and sustainable packaging design can be a significant selling point. Consider the following: Eco-friendly materials: Explore sustainable packaging materials such as recycled paper, biodegradable plastics, or reusable containers. Reduce waste: Minimize excess packaging and opt for minimalist designs that reduce material consumption. Communicate your efforts: Highlight your commitment to sustainability on the packaging to resonate with environmentally conscious consumers. Test and Iterate Once your packaging design is ready, don’t rush into production. Conduct testing and gather feedback from focus groups or surveys. Use this feedback to make necessary improvements and refinements. Iteration is key to ensuring your packaging design is as effective as possible. Collaborate with Design Professionals While marketing teams have valuable insights into their brands and audiences, it can be beneficial to collaborate with design professionals, especially for complex or specialized projects. Graphic designers, packaging engineers, and UX designers can provide expertise that complements your team’s efforts. If you are interested in packaging solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging is an essential aspect of the modern supply chain, serving as a protective shield for products, preserving their quality, and enhancing their marketability. Among the plethora of packaging materials available today, Expanded Polystyrene (EPS) foam has been a versatile and effective choice. In this comprehensive guide, we will delve into the world of EPS foam in packaging, exploring its properties, applications, benefits, environmental considerations, and more. Understanding EPS Foam What is EPS Foam? EPS foam, also commonly referred to as Styrofoam, is a lightweight and rigid plastic material derived from polystyrene. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional cushioning and insulation properties. Key Properties of EPS Foam EPS foam possesses several key properties that make it an ideal material for packaging purposes: Lightweight: It is exceptionally light, reducing transportation costs. Insulation: Offers excellent thermal resistance and moisture protection. Cushioning: Provides superior shock absorption, safeguarding products during transit. Buoyancy: EPS foam is buoyant, making it suitable for applications requiring flotation. Moldability: It can be molded into various shapes and sizes to fit a wide range of products. Recyclability: While recyclable, EPS foam recycling often requires specific facilities and processes. Applications of EPS Foam in Packaging Protective Packaging EPS foam is widely used to safeguard fragile and sensitive items during shipping. It serves as an effective cushion against impacts, vibrations, and temperature variations. Common applications include electronics, glassware, and equipment. Insulated Packaging Thanks to its exceptional insulation capabilities, EPS foam is employed for packaging temperature-sensitive goods such as food, pharmaceuticals, and chemicals. It helps maintain the desired temperature, minimizing spoilage and product damage. Void Fill and Dunnage EPS foam can be converted into loose-fill packaging or custom shapes to fill empty spaces within packages, preventing products from shifting and sustaining damage during transit. Industrial Packaging In industries such as automotive and manufacturing, EPS foam is used for bulk packaging of components and materials. It provides protection against mechanical damage and corrosion. Benefits of EPS Foam Packaging Superior Protection EPS foam’s ability to absorb shocks and vibrations ensures that products arrive intact at their destination, reducing returns and customer complaints. Lightweight The lightweight nature of EPS foam contributes to lower shipping costs and reduced fuel consumption, thereby decreasing carbon emissions. Thermal Insulation For products requiring temperature control, EPS foam acts as an efficient insulator, helping maintain product quality and safety. Customization EPS foam’s moldability allows for the creation of precisely tailored packaging solutions, minimizing waste and material usage. Cost-Effective EPS foam remains a cost-effective choice compared to many alternative packaging materials with similar protective properties. Environmental Considerations Recycling While EPS foam is recyclable, the availability of collection and recycling facilities varies by region. It is crucial for businesses and consumers to follow local recycling guidelines and utilize available facilities. Sustainable Alternatives Ongoing efforts within the industry focus on finding sustainable alternatives to EPS foam, such as biodegradable foams and other eco-friendly packaging materials. EPS Foam in a Circular Economy Extended Life EPS foam can have an extended life beyond packaging through recycling or repurposing in various applications, including construction and arts and crafts. Closed-Loop Recycling Some companies are investing in closed-loop recycling systems, which collect and reuse EPS foam packaging, contributing to a more sustainable and circular economy. If you are interested EPS foam packaging solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Expanded Polystyrene Foam Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of logistics and supply chain management, the cost of shipping plays a pivotal role in determining a company’s profitability. While factors like distance, weight, and shipping method undoubtedly influence shipping costs, one often overlooked aspect is packaging lead times. Packaging lead times refer to the amount of time it takes for a product to be prepared, packaged, and ready for shipment. In this blog, we will delve into the intricate relationship between packaging lead times and shipping costs, and how businesses can optimize this crucial element of their operations. Understanding Packaging Lead Times Before we delve into the impact of packaging lead times on shipping costs, it’s essential to understand what packaging lead times entail: Product Preparation: This involves getting the product ready for shipment. It includes quality checks, labeling, and any necessary assembly or disassembly. Packaging: Once the product is prepared, it needs to be securely and appropriately packaged to ensure it arrives at its destination intact. Packaging materials, like boxes, bubble wrap, and pallets, need to be sourced and utilized. Documentation: Preparing the required shipping documents, including customs paperwork and shipping labels, is a crucial part of packaging lead times. Storage: If products are not shipped immediately, they must be stored safely and efficiently, incurring storage costs. How Packaging Lead Times Impact Shipping Costs Inventory Holding Costs: The longer products sit in storage due to extended packaging lead times, the higher the inventory holding costs become. This includes warehousing fees, insurance, and depreciation of the stored goods. These costs can add up significantly over time. Shipping Mode Selection: Companies often choose shipping modes based on the urgency of delivery. Air freight, which is faster but more expensive, may be chosen when packaging lead times are short. Conversely, when lead times are extended, less expensive options like sea freight may be preferred. Rush Orders: In some cases, rushed packaging to meet tight delivery deadlines can result in higher labor and material costs, potentially impacting overall shipping costs. Space Utilization: Efficient packaging lead times allow for better space utilization in containers or trucks. Products that are poorly packaged or not properly consolidated may require more space and lead to additional transportation costs. Consolidation Opportunities: Longer packaging lead times provide opportunities to consolidate shipments. Combining several smaller shipments into one larger shipment can be more cost-effective, as it reduces the cost per unit transported. Customs and Compliance: Adequate packaging lead times enable companies to complete all necessary customs and compliance documentation accurately. Rushed processes may lead to errors and fines, increasing overall shipping costs. Optimizing Packaging Lead Times Forecasting: Accurate demand forecasting is crucial for planning packaging lead times effectively. Companies should use historical data, market trends, and customer orders to predict packaging requirements. Efficient Packaging Processes: Streamline and optimize your packaging processes to reduce lead times without compromising on quality. Automation and lean principles can be valuable in achieving this. Communication: Collaborate closely with suppliers and logistics partners to align packaging lead times with transportation schedules. Clear communication can help avoid unnecessary delays. Inventory Management: Do not run out of supplies by keeping enough with demand and maintaining a safety stock. Contingency Planning: Develop contingency plans for unexpected delays or spikes in demand. These plans can help maintain customer satisfaction while mitigating additional shipping costs. Conclusion Packaging lead times are a critical factor in determining shipping costs. An efficient packaging process not only reduces the time products spend in storage but also enables better transportation planning. By understanding and optimizing packaging lead times, businesses can not only reduce their shipping costs but also enhance their overall supply chain efficiency and customer satisfaction. In today’s highly competitive market, these factors can make a significant difference in a company’s success. If you are interested in packaging products, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

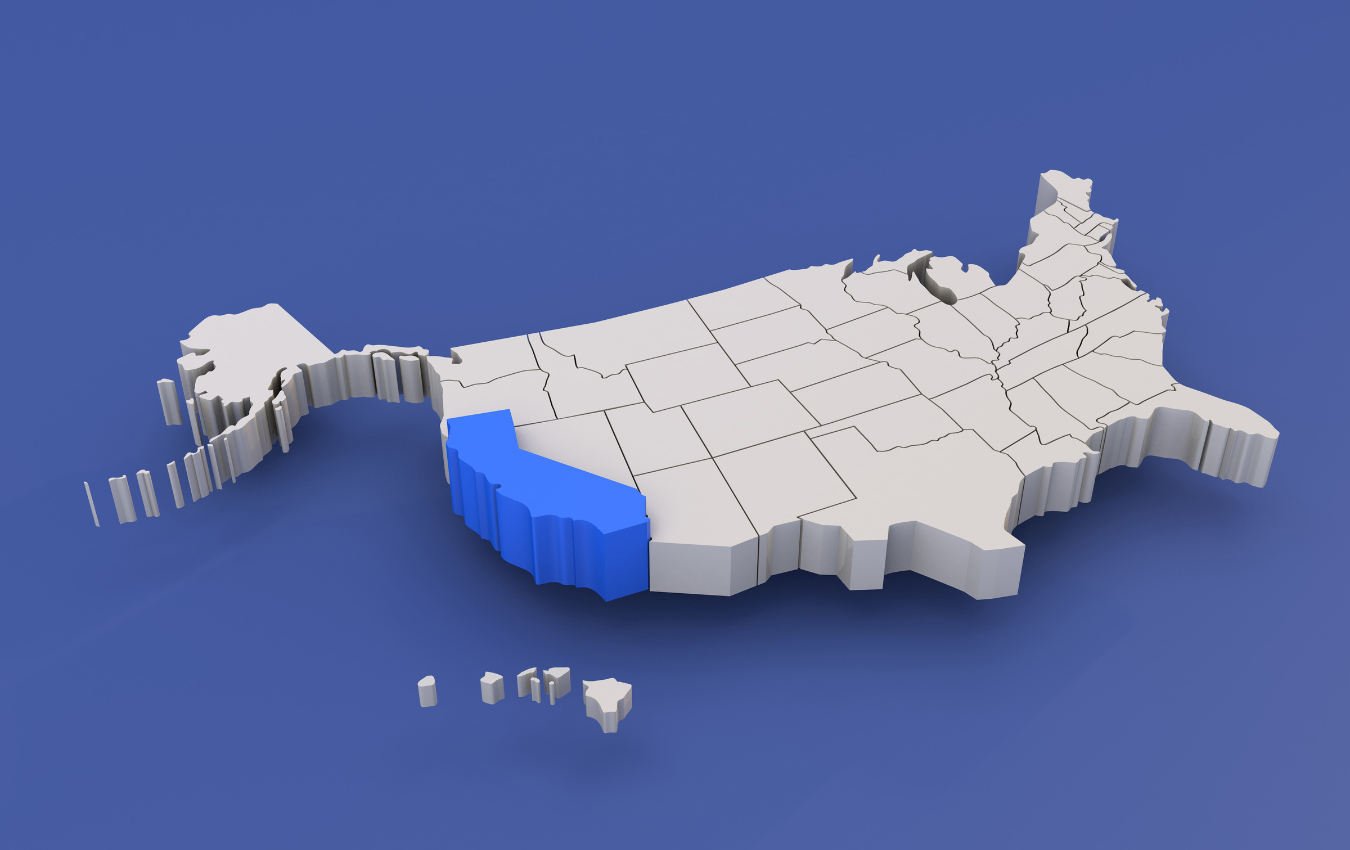

Packaging plays a crucial role in product presentation, preservation, and sustainability. While packaging regulations across the United States generally adhere to federal guidelines, California stands out for its unique and stringent packaging laws. In this blog, we will explore the differences between packaging in California and the rest of the United States, examining regulations, sustainability initiatives, and their impact on businesses and consumers. California’s Packaging Regulations: A Unique Landscape California is known for its proactive approach to environmental protection, and its packaging regulations reflect this commitment. The primary difference between California and the rest of the U.S. lies in the state’s comprehensive and strict regulations aimed at reducing packaging waste and promoting recycling. California’s Rigid Container Law One of California’s standout packaging laws is the Rigid Plastic Packaging Container (RPPC) Act, which requires manufacturers to minimize packaging waste. This law mandates that RPPCs meet specific recycling criteria, such as using a minimum percentage of recycled content and being labeled with recycling symbols. Non-compliant products may face penalties. Extended Producer Responsibility (EPR) Programs California has been at the forefront of Extended Producer Responsibility (EPR) programs. Under EPR, manufacturers bear responsibility for the entire lifecycle of their packaging, from production to disposal. They must participate in recycling programs, fund collection systems, and meet specific recycling and recovery targets. Plastic Waste Reduction Laws California has implemented multiple laws aimed at reducing single-use plastics. Bans on single-use plastic bags, straws, and expanded polystyrene (Styrofoam) food containers are examples of such regulations. These measures have significant implications for packaging choices, particularly in the food and beverage industry. Packaging Regulations in the Rest of the U.S. While California leads in packaging regulations, the rest of the United States primarily follows federal guidelines established by agencies like the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). These guidelines cover issues such as recycling labels, nutrition facts, and product safety. Federal Recycling Labeling Recycling labeling guidelines provided by the Federal Trade Commission (FTC) are used nationwide. These guidelines ensure consistency in recycling symbols and terminology. However, California may have additional requirements for products sold within the state. Variability in State Regulations Beyond federal guidelines, individual states may have their own packaging regulations, but they generally tend to be less stringent than California’s. States may focus on issues like bottle deposits or recycling programs but typically do not have laws as comprehensive as California’s RPPC Act or EPR programs. Implications for Businesses and Consumers Compliance Costs Businesses operating in California face higher compliance costs due to the state’s strict packaging regulations. They must invest in sustainable packaging materials, meet recycling targets, and navigate complex reporting requirements. These costs can affect pricing and profitability. Consumer Awareness Consumers in California tend to be more aware of packaging sustainability due to the state’s active promotion of recycling and reduction of single-use plastics. This can influence their purchasing decisions and product preferences. National Brands vs. Local Brands National brands often create standardized packaging to comply with various state regulations, including California’s. Local or smaller brands may find it challenging to navigate the patchwork of state-specific requirements. Sustainability Initiatives California’s stringent regulations have spurred innovation in sustainable packaging materials and practices. These initiatives have the potential to influence packaging trends and best practices across the nation. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the realm of packaging materials, the choice between polyethylene (PE) and laminated polyethylene foam can significantly impact the effectiveness and functionality of your packaging solutions. To make informed decisions about your packaging needs, it’s crucial to delve into the distinctions between these two foam materials. In this comprehensive comparison, we will explore the properties, applications, benefits, and drawbacks of polyethylene foam and laminated polyethylene foam specifically in the context of packaging. By the end, you’ll gain insights into which foam material best suits your unique packaging requirements. Polyethylene Foam: A Closer Look in Packaging Polyethylene foam, often referred to as PE foam, is a versatile packaging material known for its exceptional cushioning and protective qualities. Here are some key features of polyethylene foam when applied to packaging: Exceptional Cushioning: In packaging, polyethylene foam stands out for providing superior cushioning and shock absorption, making it an ideal choice for safeguarding fragile items during storage, transit, and handling. Insulation: PE foam serves as an excellent thermal insulator, which is advantageous when packaging temperature-sensitive goods, ensuring they maintain their intended conditions. Moisture Resistance: Packaging materials require protection from moisture, and PE foam delivers on this front. It is inherently resistant to moisture, preserving the integrity of packaged items even in damp environments. Customization: The flexibility of polyethylene foam allows for easy customization to accommodate the unique shapes and sizes of various products, ensuring a snug fit within the packaging. Cost-Efficiency: When it comes to packaging costs, polyethylene foam offers an economical solution, which is particularly appealing to businesses looking to balance performance and budget. Drawbacks of Polyethylene Foam in Packaging Limited Barrier Properties: While polyethylene foam excels in cushioning, it does not possess significant barrier properties against gases or liquids, which may be essential for certain packaged products. Compression Set: Over time, polyethylene foam can experience compression set, a phenomenon where it loses some of its cushioning properties if subjected to prolonged pressure. Laminated Polyethylene Foam: A Closer Look in Packaging Laminated polyethylene foam takes the versatility of polyethylene foam to another level by combining multiple layers with various materials, enhancing its performance for packaging applications. Here are some key features of laminated polyethylene foam in the context of packaging: Enhanced Strength and Durability: The lamination process reinforces the foam’s strength and durability, ensuring it can withstand the rigors of the packaging environment, protecting your products effectively. Moisture Barrier: Laminated polyethylene foam can incorporate moisture-resistant layers, an essential feature when packaging goods that must remain dry and free from water damage. Customized Properties: Laminated polyethylene foam offers versatility in packaging design. It can be tailored with added barrier films, adhesives, or additional foam layers to meet specific packaging requirements. Enhanced Insulation: In packaging applications, laminated polyethylene foam can provide superior thermal insulation properties, ensuring that temperature-sensitive items maintain their desired conditions throughout transportation and storage. Drawbacks of Laminated Polyethylene Foam in Packaging Cost Considerations: Laminated polyethylene foam typically incurs higher costs compared to standard polyethylene foam due to the additional materials and processing involved in its production. Environmental Impact: The recyclability of laminated polyethylene foam may be more challenging, depending on the specific composition of the laminate, which can impact sustainability efforts. Common Packaging Applications Polyethylene Foam (PE): PE foam is commonly used in packaging to protect fragile items, provide cushioning, and ensure product integrity during transit. It is also employed in sound insulation within packaging. Laminated Polyethylene Foam: Laminated polyethylene foam is often found in packaging solutions for delicate electronics, glassware, precision instruments, and products requiring superior insulation and moisture resistance. Conclusion In the realm of packaging materials, the choice between polyethylene foam and laminated polyethylene foam hinges on your specific packaging requirements and the nature of the products you’re packaging. While polyethylene foam excels in cushioning and cost-effectiveness, laminated polyethylene foam offers enhanced strength, durability, and customizable properties tailored to meet intricate packaging needs. When determining the ideal foam material for your packaging project, consider factors such as insulation, moisture resistance, budget constraints, and performance prerequisites. Both polyethylene foam and laminated polyethylene foam have their unique strengths, making them valuable solutions in the packaging industry, depending on the context and application. If you are interested in polyethylene or laminated polyethylene foam packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Polyethylene Foam Facebook Twitter LinkedIn Pinterest Relevant Posts