Home » Packaging: One Distributor vs. Multiple Manufacturers

Packaging: One Distributor vs. Multiple Manufacturers

Managing packaging for your business is more than just ordering boxes and labels—it’s about sourcing the right materials, coordinating timelines, ensuring quality, and staying aligned with branding and compliance standards. For many buyers, this means juggling relationships with multiple manufacturers for items like corrugated boxes, folding cartons, mailers, tapes, pouches, and displays.

But there’s a smarter, more efficient way: working with a single, full-service packaging distributor. Here’s why consolidating your packaging supply chain under one expert partner isn’t just more convenient—it can seriously improve your results.

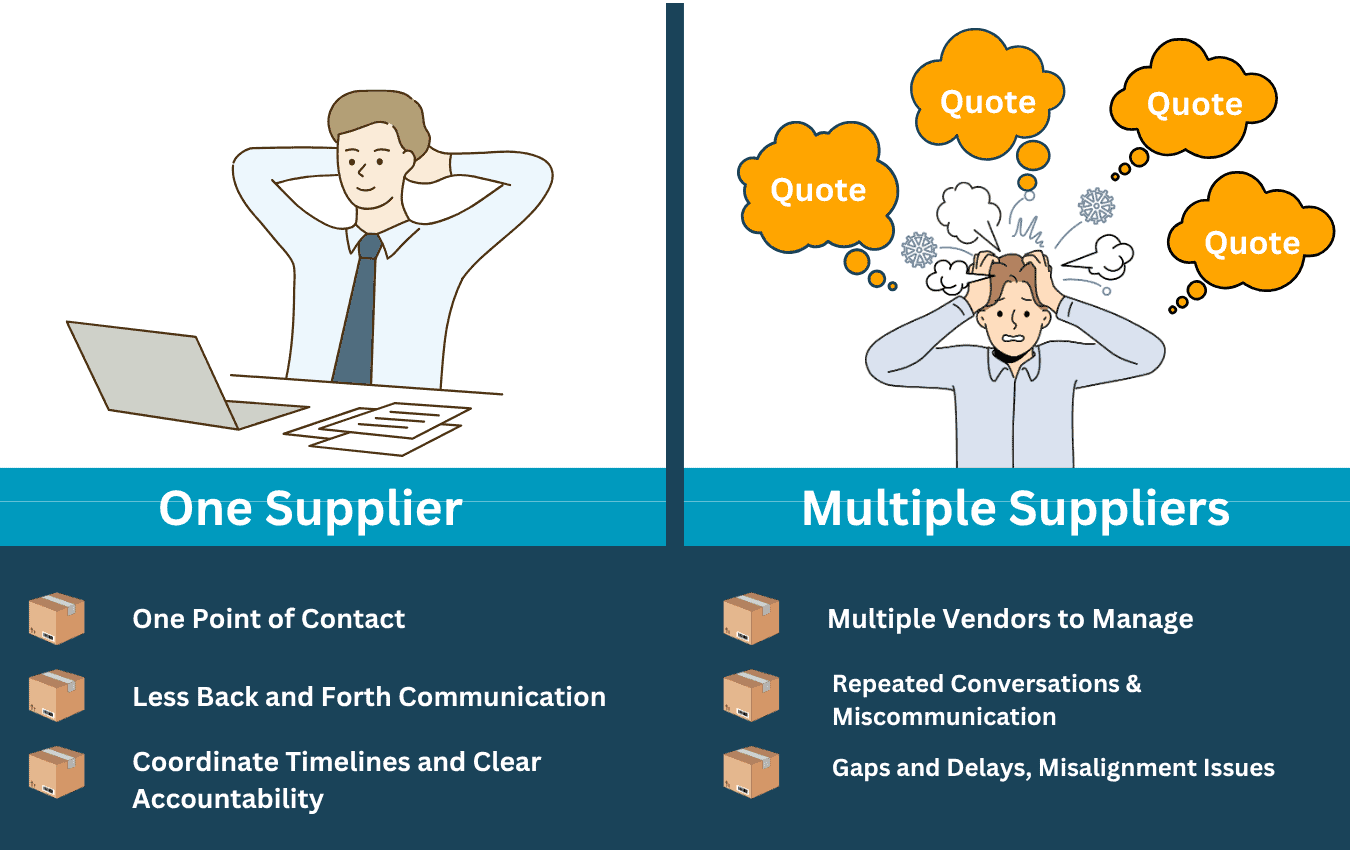

Simplified Project Management

Dealing with multiple vendors often means repeating conversations, managing disconnected timelines, and trying to align different production capabilities. A packaging distributor serves as your central point of contact, coordinating every component of your project—from sampling and quoting to delivery and fulfillment.

✔ One contact for all packaging products

✔ Less back-and-forth communication

✔ No gaps between structural design and production

✔ Clear accountability from start to finish

Faster Timelines and Better Coordination

When you work with multiple manufacturers, each one operates on their own schedule. If your folding cartons are delayed, but your rigid boxes ship early, your entire packaging launch suffers. A distributor ensures that everything is timed to arrive together, preventing slowdowns and misalignment.

✔ Synchronized production timelines

✔ Coordinated delivery and inventory planning

✔ Streamlined launches for multi-component packaging

✔ Improved speed to market

Greater Flexibility Across Packaging Types

Manufacturers typically specialize in one category—like corrugated, folding cartons, or flexible packaging. But your brand needs more than that. A distributor gives you access to a wide range of packaging formats and materials without having to build separate relationships for each one.

✔ Corrugated boxes, pouches, mailers, displays, and more

✔ One partner for stock and custom packaging

✔ Flexibility to scale or adjust based on product changes

✔ Support across retail, e-commerce, and promotional needs

Cost and Volume Optimization

Distributors work across hundreds of vendors and manufacturers, which means they can leverage volume buying, negotiate better pricing, and combine orders to keep your costs down. You’re not locked into one manufacturer’s pricing or volume limitations—your distributor finds the best fit.

✔ Access to competitive pricing through volume

✔ Lower MOQs through consolidated buying

✔ Cost savings on bundled services (design, testing, fulfillment)

✔ Custom sourcing based on your budget and goals

Customization with Consistency

When you’re managing structural design through one vendor, printing with another, and labeling elsewhere, it’s easy to lose brand consistency. A distributor helps ensure that every element of your packaging is aligned—visually and structurally—because it’s all being managed under one roof.

✔ Unified branding across all packaging types

✔ Color-matching and layout alignment

✔ Accurate sizing across inserts, boxes, and displays

✔ One design file applied across multiple formats

Support with Compliance, Sustainability, and Retail Requirements

Retailers, distributors, and regulators all have packaging requirements—and those can be hard to manage when you’re dealing with multiple suppliers who may not understand your industry. A packaging distributor understands the bigger picture and helps ensure all products meet the same standards.

✔ Knowledge of FDA, USDA, and retailer-specific requirements

✔ Recommendations for recyclable, compostable, and eco-friendly options

✔ Retail-ready display coordination (Target, Costco, Walmart, etc.)

✔ Accurate barcoding, labeling, and structural compliance

Scalability and Long-Term Partnership

As your business grows, your packaging needs evolve. A manufacturer may only serve one niche, but a distributor can scale with you—offering more product options, faster turnarounds, and additional services like fulfillment, packout, and logistics.

✔ Easy to add new SKUs or packaging formats

✔ Long-term consistency across growing product lines

✔ Ongoing optimization of cost, materials, and design

✔ Built-in support for larger retail rollouts or DTC expansion

Final Thoughts

Working with multiple packaging manufacturers might seem like a way to shop around—but in reality, it adds unnecessary complexity and cost to your process. A trusted packaging distributor gives you efficiency, control, and scalability, all while helping you get better results with fewer headaches.

Looking to simplify your packaging supply chain?

We’ll help you manage every detail—from sourcing and design to delivery—so you can focus on growing your business.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » Packaging: One Distributor vs. Multiple Manufacturers