Home » Packaging: Balancing Price, Sustainability, and Quality

Packaging: Balancing Price, Sustainability, and Quality

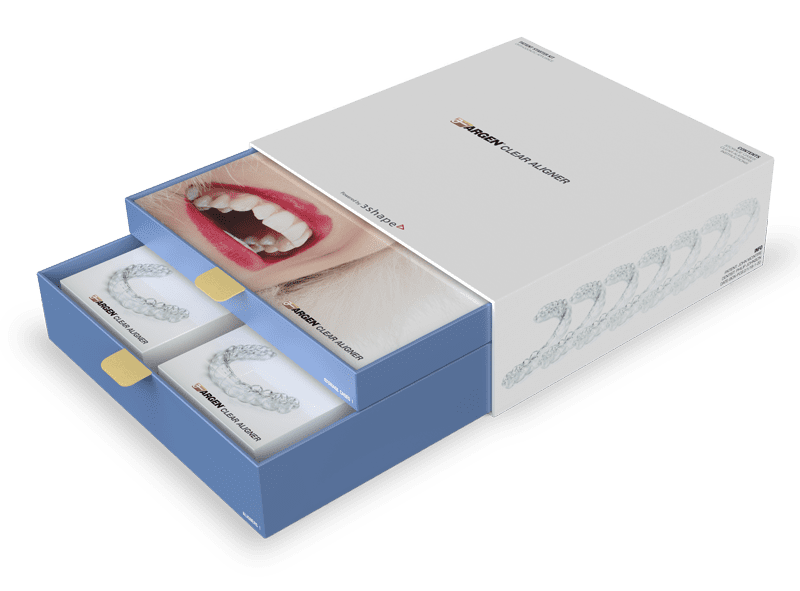

Packaging is a critical component of our daily lives, serving a dual purpose of protecting products and conveying vital information to consumers. In the wake of growing environmental concerns, the selection of packaging materials has become a focal point. In this blog, we will delve into the intricate interplay between price, sustainability, and quality in packaging.

Price

Price typically takes center stage for businesses when they contemplate packaging materials. It wields a direct impact on the financial bottom line and is a key determinant of profitability. Let’s dissect the pricing considerations for various packaging materials:

Flexible Plastic:

- Flexible plastic packaging is often the most economical choice. Its production cost is low, and its lightweight nature reduces transportation expenses. It is important to recognize that generic non-flexible plastic packaging can be more expensive depending on the application.

- Bulk purchasing of flexible plastic packaging materials is budget-friendly.

- Nevertheless, a holistic cost analysis should factor in long-term expenses, including disposal and potential harm to a brand’s reputation due to environmental concerns.

Corrugated:

- Corrugated packaging materials are generally cost-effective but may sometimes surpass flexible plastic packaging in terms of pricing.

- Customization or printing on corrugated packaging can incrementally raise costs.

- Opting for recycled corrugated materials not only contributes to cost efficiency but also promotes sustainability.

Chipboard and Paperboard:

- Chipboard and paperboard packaging materials tend to offer an economical solution.

- Their competitive pricing, coupled with their adaptability and versatility, make them suitable for a wide spectrum of products.

- Utilizing recycled chipboard and paperboard further enhances their cost-effectiveness and sustainability.

Flexible Plastic

Corrugated

Chipboard/Paperboard

Sustainability

As global environmental consciousness continues to rise, sustainability has emerged as a pivotal factor in packaging decisions. Sustainable packaging aims to minimize its ecological impact across its entire lifecycle. Here’s how different materials stack up in terms of sustainability:

Plastic:

- Traditional plastic packaging is often criticized for being non-biodegradable and for exacerbating plastic pollution.

- However, innovations such as biodegradable plastics and recycled PET offer more sustainable alternatives.

Corrugated:

- Corrugated packaging is generally regarded as a more sustainable option, especially when sourced from responsibly managed forests or containing recycled content.

- Its biodegradability and ease of recycling bolster its eco-friendly credentials.

Chipboard and Paperboard:

- Chipboard and paperboard packaging materials inherently possess sustainability attributes, often originating from renewable sources like wood pulp.

- Their recyclability and biodegradability make them environmentally responsible choices.

Quality

Packaging quality plays a pivotal role in safeguarding products, preserving their integrity, and enhancing the overall customer experience. Here’s how different materials perform concerning quality:

Plastic:

- Plastic packaging excels in protecting products from moisture and is highly resistant to breakage.

- However, it may not be suitable for products requiring breathability or specific temperature conditions.

Corrugated:

- Corrugated packaging offers versatility and can be tailored to accommodate various product types.

- It is particularly well-suited for dry goods and provides robust protection when designed effectively.

Chipboard and Paperboard:

- Chipboard and paperboard packaging are renowned for their adaptability and quality, making them suitable for a diverse range of products.

- They excel in maintaining product integrity and are an excellent choice for items sensitive to light or air.

If you are looking for custom packaging solutions tailored to your needs, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Packaging: Balancing Price, Sustainability, and Quality

Shipping costs surge during the holiday season as carriers raise rates and surcharges. For packaging buyers, box design directly impacts freight spend. Oversized cartons, excess

As we approach 2024, the packaging industry continues to evolve, responding to both technological advancements and shifting consumer preferences. From sustainable materials to smart packaging,

Temperature fluctuations can have a detrimental effect on your products and packaging. Whether your goods are sensitive to extreme heat or cold, maintaining the right