Home » Maximizing Protection with Gaylord Boxes

Maximizing Protection with Gaylord Boxes

The packaging world is vast, catering to various industry needs and requirements. Among the myriad options, Gaylord boxes stand out for their durability, versatility, and sustainability. Initially designed for shipping agricultural products, they’ve evolved to serve multiple sectors, ensuring products are shielded effectively. Let’s explore how these boxes can provide unparalleled protection for your goods.

What is a Gaylord Box?

A Gaylord box, often referred to as a bulk box or pallet box, is a large corrugated container predominantly used for bulk shipping and storage. They are known for their strength and capability to handle weighty items, coming in varied sizes and strengths based on the number of corrugated layers they contain.

Key Features of Gaylord Boxes Enhancing Protection

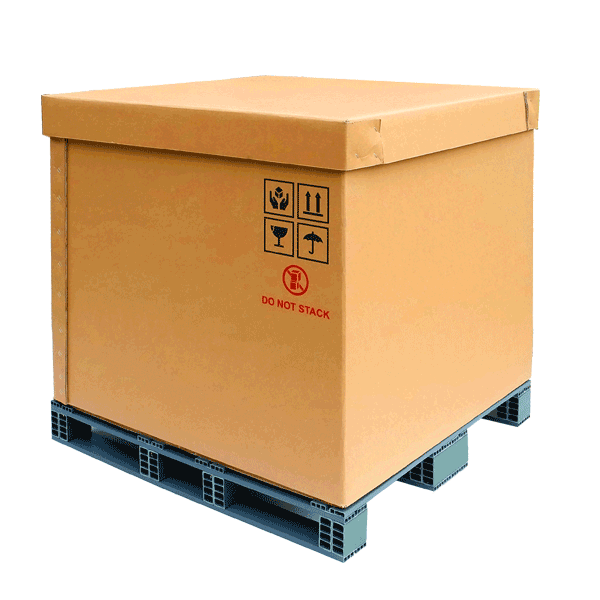

Multi-layered Design: The inherent strength of Gaylord boxes comes from their multi-layered corrugated structure. This design makes them robust and resistant to external pressures.

Reinforced Corners: Another significant feature of these boxes is their reinforced corners. This ensures they support the weight of their contents without giving way.

Broad Flaps: The flaps on these boxes are wide and may overlap, providing a cushioning effect that adds another protective barrier against external impacts.

Sustainable and Reusable

Beyond their protective attributes, Gaylord boxes champion sustainability. Made primarily from recycled materials, they are eco-friendly. Their sturdy design means they can be reused several times, leading to reduced environmental waste.

Versatility in Use

Gaylord boxes are versatile. They can hold a range of items, from agricultural produce to automotive parts. This adaptability ensures the contents receive maximum protection against external variables.

Efficient for Storage and Transport

Their standardized dimensions mean they can be stacked effectively in storage facilities, making the most of available space. This same uniformity makes them a favorite for transportation as they are easily loaded onto transportation vehicles, assuring a safe passage for goods.

Enhanced Protection with Complementary Materials

When combined with other protective packaging materials, such as bubble wrap or foam inserts, the defensive capabilities of Gaylord boxes increase exponentially, ensuring products remain unscathed.

Conclusion

Gaylord boxes are a testament to how packaging can be both effective and eco-friendly. Whether you’re an entrepreneur searching for bulk shipping solutions or someone needing robust storage options, Gaylord boxes are a top-tier choice. Their blend of durability, environmental responsibility, and adaptability positions them as a preferred option for those who prioritize the safekeeping of products.

If you are interested in gaylord boxes, then partner with Brown Packaging today to get started.

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Home » Maximizing Protection with Gaylord Boxes

Why Holiday Fulfillment Demands Precision The holiday season introduces a unique set of pressures across the packaging and supply chain landscape—especially for businesses managing kitting,

In today’s fast-paced world, one industry that keeps businesses and individuals connected is the shipping and mailing industry. An often overlooked but crucial component of

Protein bars are a popular on-the-go snack, requiring durable, protective, and visually appealing packaging to ensure freshness and convenience. The right packaging helps extend shelf