Home » Mastering Quality Control in POP Production

Mastering Quality Control in POP Production

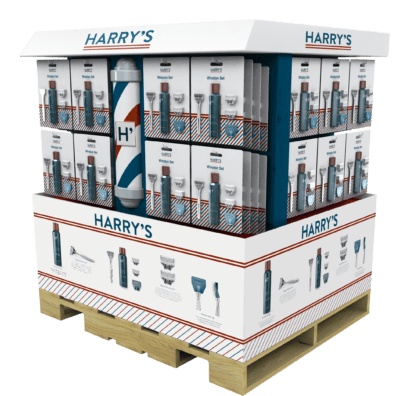

Once the design and material selection for a Point of Purchase (POP) display are locked in, the project moves into the critical production phase. This stage is where your concept is transformed into a tangible product ready for retail environments. The key to successful production lies in stringent quality control measures and a well-coordinated manufacturing process. This blog outlines the essential steps and considerations for the production phase of POP displays, ensuring each unit is built to meet both aesthetic and functional standards.

Streamlining the Manufacturing Process

Setting Up the Production Line

The first step in the production phase is setting up the manufacturing line. This setup should be optimized based on the design specifications and material requirements of the POP display. Efficient line setup helps minimize production time and cost, ensuring that each component is assembled correctly and efficiently.

Integrating Technology and Automation

Where possible, integrating advanced manufacturing technologies and automation can enhance precision and speed in the production process. Automation can be particularly beneficial in producing components that require consistent replication of detailed designs, contributing to uniformity and quality across all units.

Implementing Quality Control Measures

Developing Quality Standards

Before production begins, establish clear quality standards that align with the display’s design and functionality goals. These standards should cover all aspects of the display, including material integrity, color accuracy, structural stability, and overall finish.

Continuous Quality Monitoring

Implement continuous quality monitoring throughout the production process. This involves regular inspections and testing of the displays at various stages of manufacturing. By catching defects or deviations early, you can prevent issues that might compromise the final product’s effectiveness.

Feedback Loop with Design and Materials Teams

Maintain a feedback loop with the design and materials teams. This collaboration ensures that any potential issues identified during production can be traced back to design or material choices and addressed promptly, preventing recurrence.

Ensuring Compliance with Specifications

Adherence to Design Specifications

It’s crucial that the manufacturing process adheres strictly to the agreed-upon design specifications. This adherence prevents variations that could affect how the display performs in its intended retail environment and ensures that all functional and aesthetic elements are preserved.

Alignment with Material Specifications

Similarly, ensure that the materials used in production match the specifications decided during the planning phase. Using the correct materials affects not only the display’s look and feel but also its durability and impact in a store setting.

Preparing for Post-Production

Assembly and Pre-Installation Checks

If the display requires assembly post-production, conduct thorough checks to ensure all parts fit together correctly and that assembly is as straightforward as possible. These checks can help streamline the installation process later on.

Final Quality Assurance

Before the displays are shipped, a final quality assurance check should be conducted. This final review ensures that every display unit meets your brand’s quality standards and is ready for deployment without needing further modifications.

Conclusion

The production phase is where your POP display comes to life. By focusing on efficient production setups, stringent quality control, and strict adherence to specifications, you can ensure that the manufactured displays meet the desired standards. Thorough planning and monitoring during this phase lay the groundwork for effective POP displays that attract attention and withstand the demands of the retail environment, ultimately driving sales and enhancing brand presence.

If you are interested in POP displays, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Mastering Quality Control in POP Production