Home » How to Reduce the Risk of Glass Breaking During Transit

How to Reduce the Risk of Glass Breaking During Transit

Shipping glass products can be challenging due to their fragile nature. Whether you’re shipping glass jars, bottles, or other delicate items, the packaging you choose plays a critical role in ensuring their safe arrival. This guide provides practical strategies and materials to protect glass during transit, reducing the risk of damage.

Tips for Protecting Glass During Transit

Minimize Empty Space

Empty space inside the package allows glass items to move around, increasing the likelihood of breakage.

• Choose packaging that closely fits your product dimensions.

• Fill any gaps with cushioning materials like foam, packing peanuts, or bubble wrap.

Pro Tip: Use dividers or molded inserts to keep multiple items secure and separate.

Use Durable Boxes

Your choice of shipping box can make or break your packaging strategy—literally.

• Sturdy cardboard or corrugated boxes provide better protection than thin or flimsy options.

• Consider weather-resistant materials to protect against moisture during transit.

Pro Tip: Double-boxing adds an extra layer of protection for particularly fragile or valuable glass items.

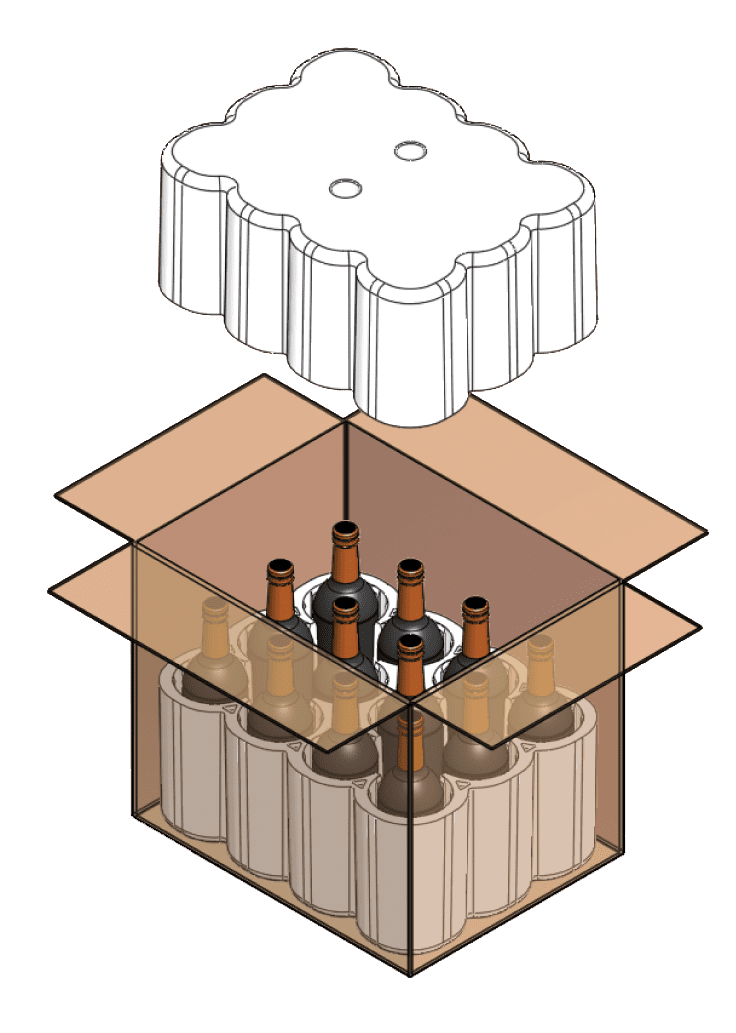

Invest in Custom Packaging

Custom packaging solutions are tailored to your product’s specific needs.

• Custom-fitted boxes, foam or molded pulp inserts keep items secure and reduce movement.

• These options often incorporate materials designed to absorb shock and protect against impacts.

Pro Tip: Custom packaging may have a higher upfront cost but often saves money by reducing breakage and returns.

Test Your Packaging Before Shipping

Simulate real-world shipping conditions to identify potential weaknesses in your packaging.

• Drop tests and vibration tests can help ensure your materials hold up under stress.

• Make adjustments to address any vulnerabilities.

Pro Tip: Testing your packaging can also help you optimize material usage, balancing protection with cost efficiency.

Best Materials for Shipping Glass

Bubble Wrap

Lightweight and versatile, bubble wrap provides excellent cushioning.

• Use it to wrap individual items tightly and secure with tape.

• Place additional layers around the product if needed.

Cons: Not eco-friendly and can be time-consuming to apply.

Molded Pulp Inserts

Custom-shaped from recycled materials, molded pulp provides a snug fit for glass items.

• Protects against movement and shock.

• Biodegradable and easy to recycle.

Cons: Higher cost and requires a steady supply of recycled materials.

Corrugated, Chipboard, Foam Inserts & Partitions

These inserts help stabilize and protect individual items during transit.

• Corrugated inserts offer strong structural support and can be customized to fit product shapes.

• Chipboard inserts provide a thinner, eco-friendly option ideal for lighter products or presentation.

• Foam inserts absorb shock and protect fragile items with precision cutouts.

• Partitions keep multiple items separated to prevent internal impact.

Cons: May require custom tooling or design, but provide significant value in protection and product organization.

Wrapping Paper

An affordable and eco-friendly option for additional cushioning.

• Use in combination with other materials to fill gaps or wrap items.

Cons: Thin and unable to absorb significant shock on its own.

Packing Peanuts

Lightweight and shock-absorbent, packing peanuts fill empty spaces effectively.

• Ensure items are tightly surrounded to prevent shifting.

Cons: Less environmentally friendly and can be messy to handle.

How to Pack Glass Jars for Shipping

Wrap Each Jar Securely: Use bubble wrap, molded pulp, or other protective materials.

Insert Dividers: Keep jars separate to avoid collisions.

Seal Liquids: Place liquid-filled jars in leak-proof bags before wrapping.

Fill Empty Spaces: Use packing peanuts or crumpled paper to stabilize items.

Reinforce the Box: Use sturdy tape to seal the box and reinforce the seams.

Final Packing Steps

Layer the Base: Place at least 3 inches of cushioning material at the bottom of the box.

Position the Items: Place glass products in the center, away from edges.

Top Layer: Add another layer of cushioning to protect the top.

Seal and Label: Secure the box with packing tape and add “Fragile” labels to inform handlers.

Why Proper Packaging Matters

Shipping fragile items like glass is a challenge, but investing in the right packaging materials and techniques can significantly reduce breakage. Properly protected items not only ensure customer satisfaction but also save you money on replacements and returns.

Need expert advice on packaging solutions?

Contact us today to explore custom options for your shipping needs!

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » How to Reduce the Risk of Glass Breaking During Transit