Home » How Packaging Suppliers Streamline Rigid Boxes for Retail

How Packaging Suppliers Streamline Rigid Boxes for Retail

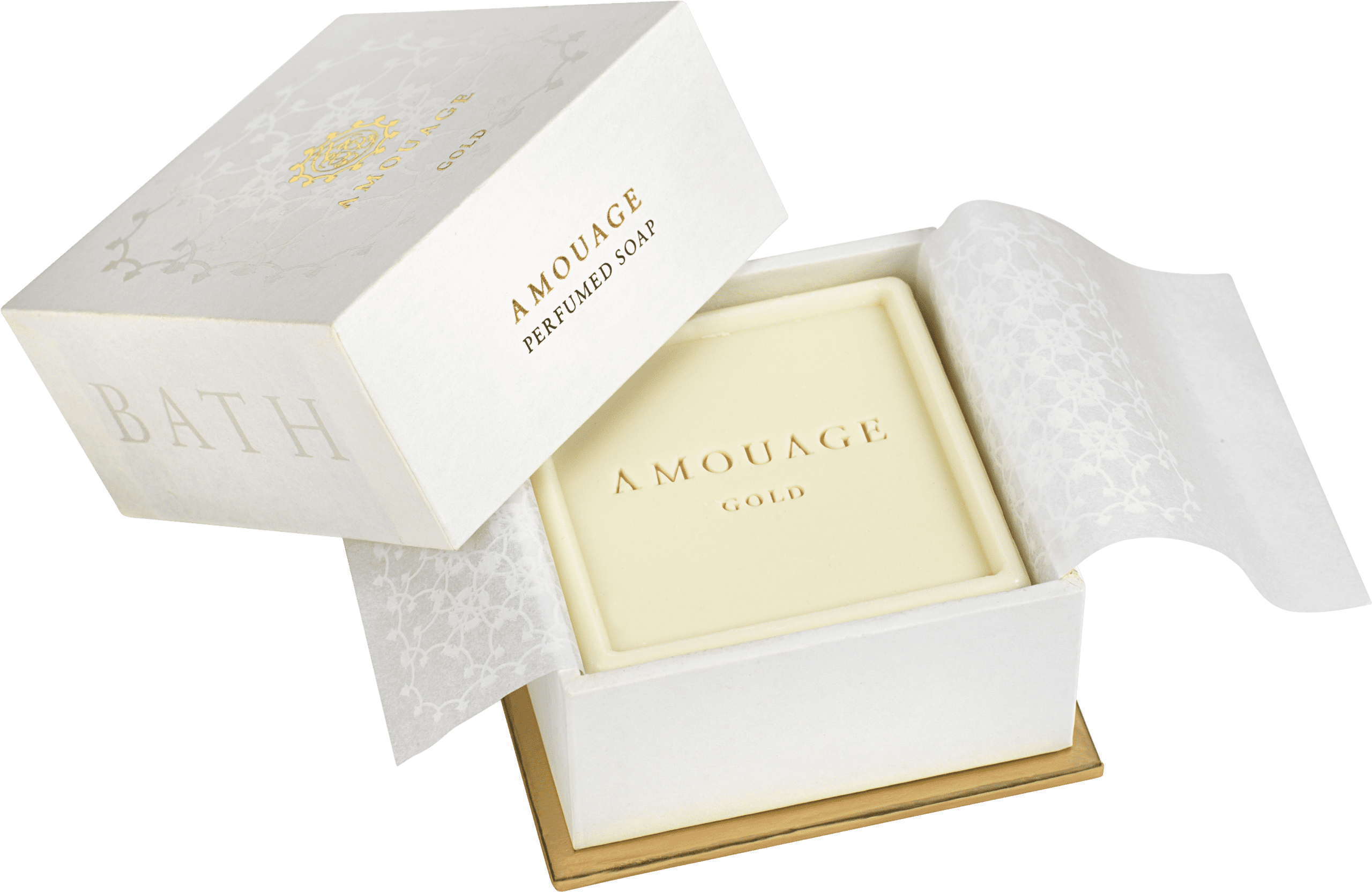

Rigid boxes are the premium standard in packaging—perfect for luxury products, high-end electronics, skincare, and gift sets. But creating a beautiful rigid box is only part of the process. To succeed in retail, your packaging must also meet strict retailer requirements, ensure supply chain efficiency, and deliver an exceptional unboxing experience for the customer.

That’s where the right packaging supplier makes a real difference. From early design support to final delivery, a knowledgeable supplier helps streamline every stage of your rigid box project—so you can get to market faster, stay compliant, and reduce costly packaging missteps.

Aligning Structural Design with Retail Requirements

Every major retailer—Target, Sephora, Walmart, Ulta, Costco—has its own set of packaging specs. A qualified packaging supplier understands these standards and helps ensure your rigid box design meets them from day one.

They’ll help you:

- Choose the right box dimensions and formats for shelf compatibility

- Design boxes that are stackable, protective, and easy to merchandise

- Comply with weight, display, and material restrictions

- Avoid common issues that cause costly rejections

✅ Saves time on approvals

✅ Prevents repackaging or reworking

✅ Positions you for smoother retailer onboarding

Coordinating Print, Finishes & Branding for Consistency

Retail-ready rigid boxes need to stand out visually while maintaining strict brand consistency across SKUs and product lines. A packaging supplier can oversee the full process—ensuring your logo placement, colors, and finishes are correct on every box, no matter the quantity.

They’ll also advise you on:

- Matching existing packaging elements

- Choosing finishes that enhance shelf appeal (foil, embossing, soft-touch)

- Selecting print methods (offset, digital) that meet timeline and volume needs

- Incorporating interior printing or custom inserts for elevated presentation

✅ Elevates product value and brand perception

✅ Supports promotional versions or line extensions

✅ Helps meet retailer expectations for premium packaging

Managing Production and Lead Times Efficiently

One of the biggest challenges with rigid boxes is the longer production time compared to other packaging formats. Working with a supplier means you’ll have production timelines mapped out, risks flagged early, and inventory timed to meet retail delivery windows.

Suppliers help with:

- Coordinating multiple components (base, lid, insert, printing)

- Managing long-lead finishes like embossing or foil

- Setting expectations for inventory drop dates

- Avoiding bottlenecks caused by fragmented communication

✅ Helps you hit critical launch dates

✅ Reduces delays from scattered sourcing

✅ Provides transparency and timeline accountability

Offering Samples, Prototypes, and Pre-Press Checks

Before full production, your supplier can create physical samples or digital proofs to ensure everything—from structure to graphics to fit—is perfect. This step is especially important when dealing with multiple SKUs or new retail accounts.

What they provide:

- Full production mockups or white samples for review

- Guidance on packaging dielines and layout

- Print file proofing for color, resolution, and layout accuracy

- Pre-production testing for inserts, closures, and durability

✅ Reduces costly production mistakes

✅ Ensures fit and finish meets expectations

✅ Speeds up retailer approval and compliance

Supporting Fulfillment, Assembly & Shipping Optimization

Many retailers require fully assembled, filled, or shelf-ready packaging. Your supplier can often assist with kitting, packout, or coordination with your co-packer or fulfillment partner to make sure your rigid boxes are ready to go right out of the box.

They can help:

- Pre-build boxes with inserts, tissue, and product placement

- Label, barcode, or shrink-wrap to meet retailer specs

- Pack efficiently for pallet optimization and damage prevention

- Prepare packaging to meet e-commerce AND retail requirements

✅ Reduces labor and fulfillment complexity

✅ Delivers a true turnkey solution

✅ Increases speed to shelf or customer

Staying Compliant with Regulations and Sustainability Trends

Retailers expect packaging to meet increasing standards for sustainability, labeling, and material sourcing. A knowledgeable supplier helps you stay ahead of compliance and align with retail trends.

Support may include:

- Guidance on recyclable or eco-friendly materials

- Compliance with food-safe or cosmetic-safe materials

- Material reduction strategies for reduced carbon footprint

- Providing certifications or documentation for retail requirements

✅ Positions your brand as forward-thinking

✅ Prevents compliance delays or rejections

✅ Helps meet retailer sustainability scorecards

Final Thoughts

Rigid boxes can elevate your product—but only when they’re backed by the right strategy, materials, and execution. A reliable packaging supplier helps you do more than just create a beautiful box—they streamline the entire process for retail readiness, brand consistency, and supply chain success.

Need help getting your rigid boxes ready for retail?

We’ll guide you through every step—from design and printing to compliance and delivery—to help you launch with confidence.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » How Packaging Suppliers Streamline Rigid Boxes for Retail