Home » How Much Weight Can a Corrugated Box Hold?

How Much Weight Can a Corrugated Box Hold?

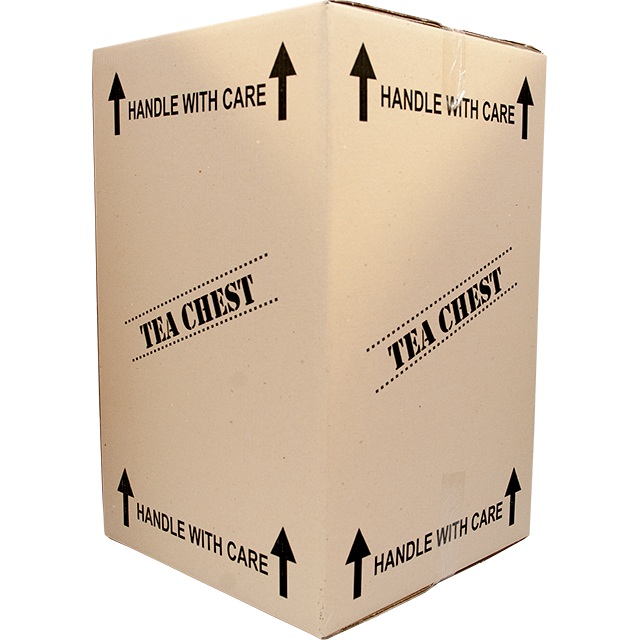

The weight a corrugated box can hold depends on factors such as box construction, material grade, flute size, and box dimensions. Corrugated boxes are designed to protect and hold items during storage and shipping efficiently. A standard single-wall corrugated box can hold between 20 to 120 pounds, while double-wall constructions can support significantly higher weights ranging from 80 to 180 pounds.

Understanding Corrugated Box Strength

Corrugated box strength is determined by multiple factors, including construction, material grade, and flute size. Understanding these variables ensures the right box is chosen for the job.

Box Construction

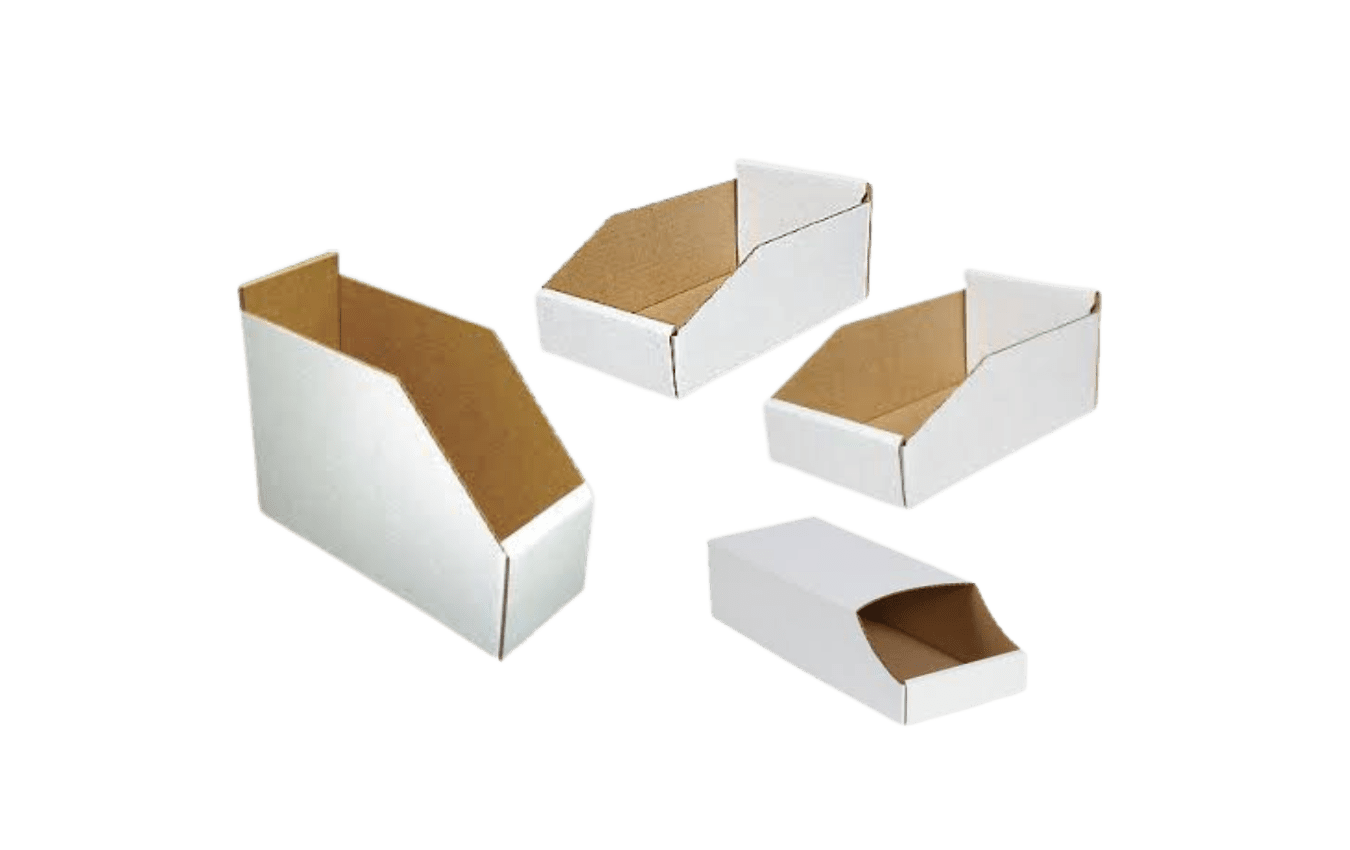

Corrugated boxes are available in three main constructions:

- Single-Wall Boxes: Suitable for lighter items with weight capacities ranging from 20 to 120 lbs, depending on the material strength.

- Double-Wall Boxes: Designed for heavier or fragile items, supporting weights from 80 to 180 lbs.

- Triple-Wall Boxes: Used for exceptionally heavy items, such as industrial equipment, capable of holding hundreds of pounds.

Material Strength: Bursting Test and Edge Crush Test (ECT)

Two key measurements determine corrugated box strength:

- Bursting Strength Test: Measures the force required to rupture the surface of corrugated board.

- Edge Crush Test (ECT): Measures stacking strength and indicates how much weight a box can withstand before collapsing.

The following tables summarize the equivalencies for single-wall and double-wall corrugated boxes:

Single-Wall Corrugated Boxes

Bursting Test | Minimum Edge Crush Test (ECT) | Maximum Suggested Loading Limit Per Carton |

125# | 23 ECT | 20 lbs. |

150# | 26 ECT | 35 lbs. |

175# | 29 ECT | 50 lbs. |

200# | 32 ECT | 65 lbs. |

275# | 44 ECT | 95 lbs. |

350# | 55 ECT | 120 lbs. |

Double-Wall Corrugated Boxes

Bursting Test | Minimum Edge Crush Test (ECT) | Maximum Suggested Loading Limit Per Carton |

200# | 42 ECT | 80 lbs. |

275# | 48 ECT | 100 lbs. |

350# | 51 ECT | 120 lbs. |

400# | 61 ECT | 140 lbs. |

500# | 71 ECT | 160 lbs. |

600# | 82 ECT | 180 lbs. |

These standardized tests ensure the durability and reliability of corrugated boxes, helping buyers choose boxes that meet their weight requirements.

The Role of Flute Size

Corrugated boxes use fluted sheets to provide strength and cushioning. Larger flutes (like A or B flutes) offer better compression resistance and are ideal for heavier items, while smaller flutes (like E or F flutes) provide a smoother surface for printing and are better for lightweight items.

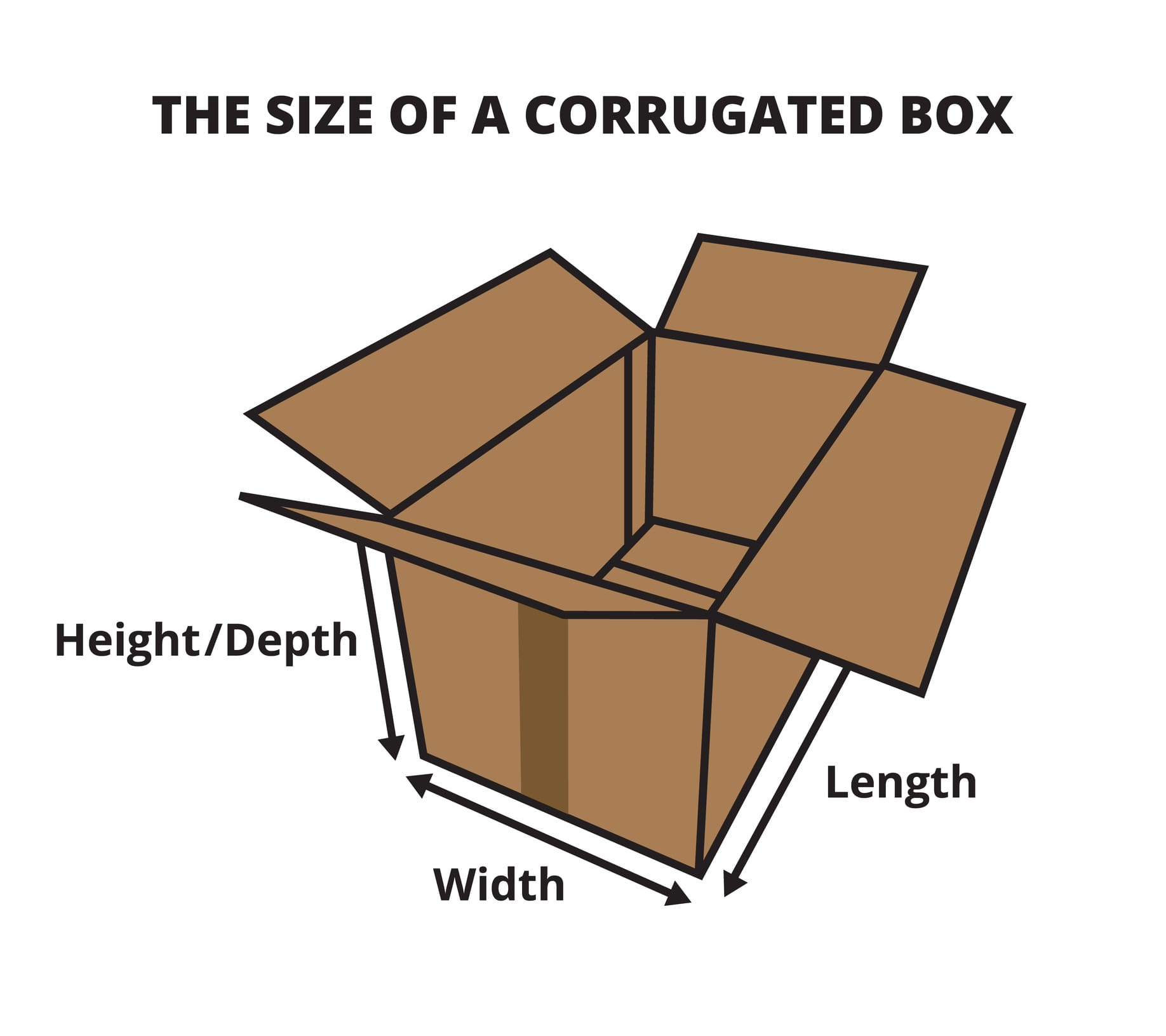

The Importance of Box Dimensions

Box size directly affects weight capacity and strength. Larger boxes have a wider surface area, which can distribute weight evenly but may require stronger materials to prevent collapse. Choosing the appropriate box size can optimize load support and minimize material waste.

How to Choose the Right Box

To ensure optimal performance, consider the following when selecting a corrugated box:

- Determine the Weight of the Contents

Use the tables above to match the weight of your products with the appropriate box strength. - Evaluate the Box Construction

- Single-wall for lightweight items.

- Double-wall for medium to heavy items.

- Triple-wall for extremely heavy or industrial goods.

- Consult with Suppliers

Collaborate with packaging experts to select boxes with the proper ECT or bursting strength for your application. - Optimize for Sustainability

Choose boxes made from recycled or sustainable materials without compromising strength.

Conclusion

The weight a corrugated box can hold depends on its construction, material grade, and strength ratings (ECT and bursting test). Single-wall boxes can hold up to 120 lbs, while double-wall boxes can support weights up to 180 lbs, as shown in the tables above. By understanding these key metrics and factors, packaging buyers can confidently choose the right boxes for their needs, ensuring products are protected during shipping and storage.

Partner with Brown Packaging today to find corrugated boxes designed to meet your weight, size, and durability requirements. Whether you’re shipping lightweight goods or industrial equipment, we’ve got the solution for you!

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » How Much Weight Can a Corrugated Box Hold?