Home » Holiday Packaging and Supply Chain Stress

Holiday Packaging and Supply Chain Stress

The holiday season pushes packaging supply chains to their limits. With surging e-commerce demand, constrained carrier capacity, and rising material costs, packaging buyers must navigate a complex landscape. The right packaging choices can ease stress on the supply chain, while poor design or sourcing decisions can amplify bottlenecks, drive up costs, and increase product damage.

How the Holiday Season Strains Supply Chains

- Higher order volumes: Warehouses and carriers face peak loads.

- Material shortages: High demand for corrugated and mailers creates lead time risks.

- Carrier delays: Overloaded networks increase transit times and handling.

- Labor constraints: Seasonal staff may have less training in handling.

These factors combine to increase both risk and cost for packaging programs

Packaging Strategies to Reduce Stress

- Source early: Secure corrugated, mailers, and all packaging materials before peak demand.

- Standardize SKUs: Fewer box sizes streamline fulfillment and stocking.

- Right-size for freight: Reduce DIM charges and optimize pallet loads.

- Reinforce durability: Stronger boxes prevent returns from mishandling.

- Flat-pack efficiency: Displays and cartons that ship compactly save space.

Balancing Speed and Protection

The challenge lies in balancing speed with durability. Overbuilt boxes slow down assembly and inflate costs, while underbuilt packaging risks damage and returns. Buyers must focus on:

- Identifying high-risk SKUs for reinforced protection.

- Using inserts or coatings to strengthen vulnerable products.

- Testing packaging under simulated peak season conditions.

The Role of Sustainability in Peak Season

Shoppers expect sustainable packaging even during high-volume periods. Supply chain stress is amplified when packaging is overbuilt or wasteful. Using recyclable corrugated or paper-based void fill balances eco goals with functionality.

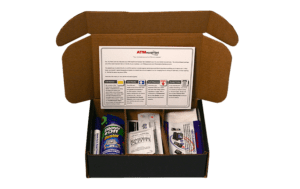

Holiday Packaging Solutions with Brown Packaging

Brown Packaging helps brands prepare for peak season by engineering packaging that reduces supply chain stress. From durable corrugated solutions to optimized freight efficiency, our programs balance cost, sustainability, and performance. Contact us to get your packaging supply chain ready for the holidays.

References

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

GS1. (2022). Retail Supply Chain Standards for Packaging and Logistics. Retrieved from https://www.gs1.org

UPS. (2023). Holiday Shipping Deadlines and Carrier Capacity Updates. Retrieved from https://www.ups.com

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Holiday Packaging and Supply Chain Stress