Home » High Density and Low-Density Polyethylene Explained: Packaging Applications & Benefits

High Density and Low-Density Polyethylene Explained: Packaging Applications & Benefits

High density polyethylene (HDPE) and low-density polyethylene (LDPE) are both types of polyethylene, a thermoplastic polymer made from petroleum. The main difference between the two is the density of the material. HDPE has a higher density and a higher molecular weight, while LDPE has a lower density and a lower molecular weight.

HDPE Packaging Applications

In terms of packaging applications, HDPE is commonly used for making rigid containers like milk jugs, water bottles, and plastic drums. It is also used in the manufacturing of pipes and fittings for the transportation of gas and water. HDPE is known for its strength and durability, making it a popular choice for packaging products that need to withstand rough handling or transportation. It also has good chemical resistance, making it suitable for packaging products that may come into contact with chemicals.

Benefits of HDPE

Benefits of HDPE include: High strength, high stiffness, good chemical resistance, good impact resistance and good temperature resistance. Disadvantages of HDPE include: It is less flexible, difficult to print on and is more prone to cracking under stress.

LDPE Packaging Applications

On the other hand, LDPE is commonly used in packaging applications such as plastic wraps, food storage bags, and squeezable bottles. Its flexibility and versatility make it a good choice for packaging products that need to be flexible, such as bags and films. It is also used to make plastic films for packaging and in the electrical and electronic industries. LDPE’s flexibility is also an advantage for packaging products that need to be vacuum-sealed or shrink-wrapped.

Benefits of LDPE

Benefits of LDPE include: Its flexibility and versatility, good electrical insulation, good chemical resistance, and low cost. Disadvantages of LDPE include: it is less stiff, less strong and has lower temperature resistance, and is more likely to crack and wear over time.

Which one should you choose?

When deciding whether to use HDPE or LDPE for packaging, it is important to consider the properties of the product being packaged and the specific requirements of the packaging. For example, if the product requires a strong and durable container that can withstand rough handling or transportation, HDPE would be a good choice. On the other hand, if the product requires a flexible and versatile packaging that can be vacuum-sealed or shrink-wrapped, LDPE would be a better choice. Additionally, if you’re looking for a printing option on the packaging, HDPE may not be ideal as it can be difficult to print on.

If you are interested in HDPE or LDPE material packaging products, then contact Brown Packaging today. We can offer our clients a wide selection of flexible packaging options and customization.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » High Density and Low-Density Polyethylene Explained: Packaging Applications & Benefits

High Impact Polystyrene, commonly known as HIPS, is a versatile and widely used thermoplastic renowned for its unique blend of properties. This material is crucial

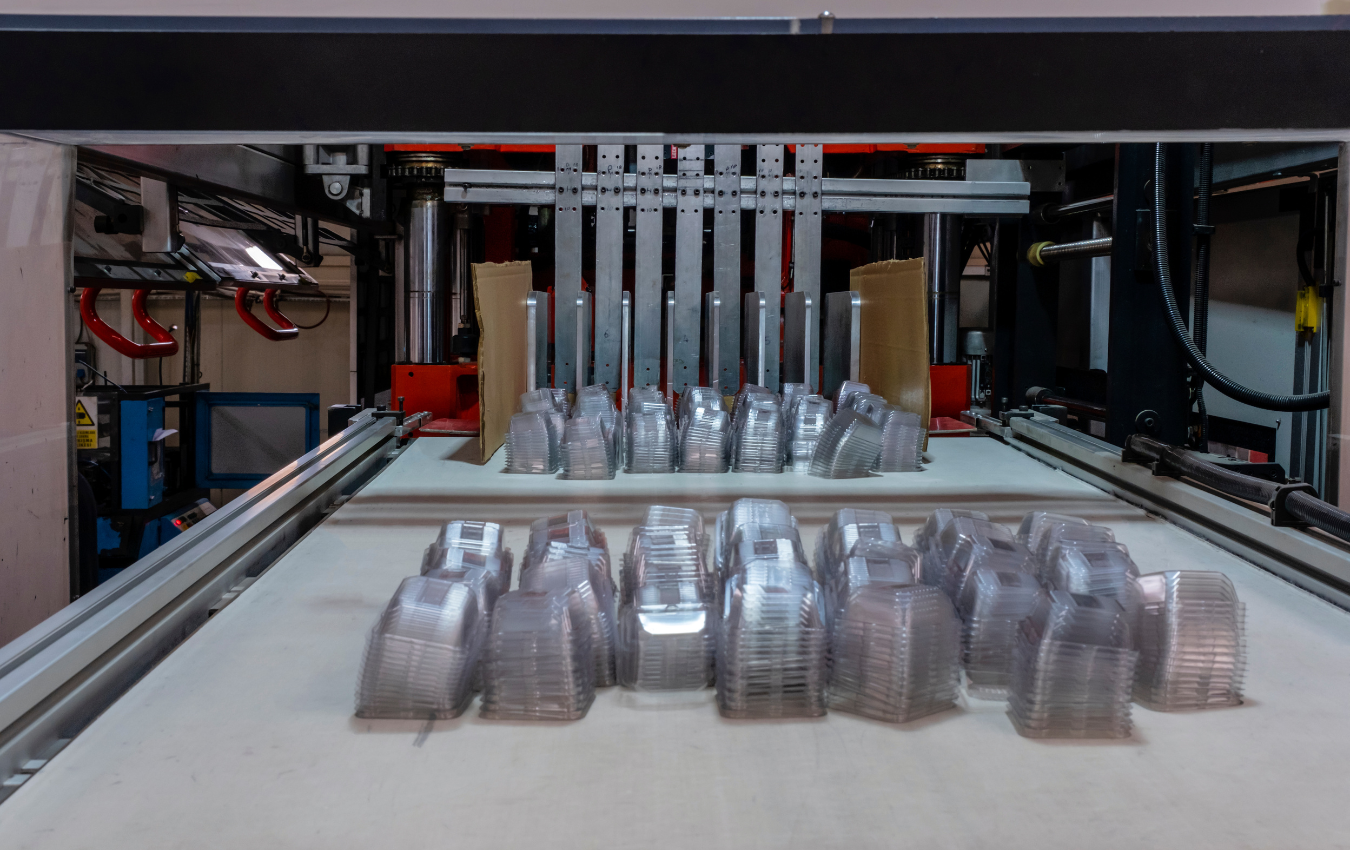

Thermoform packaging is the backbone of numerous sectors including food, pharmaceutical, electronics, cosmetics, and consumer goods, to name a few. Its high adaptability and customizability

Polypropylene, often referred to as PP plastic, is the second most widely used plastic globally, praised for its remarkable durability, strength, and resistance to various