Home » Food Labeling Regulations: A Guide for Packaging Buyers

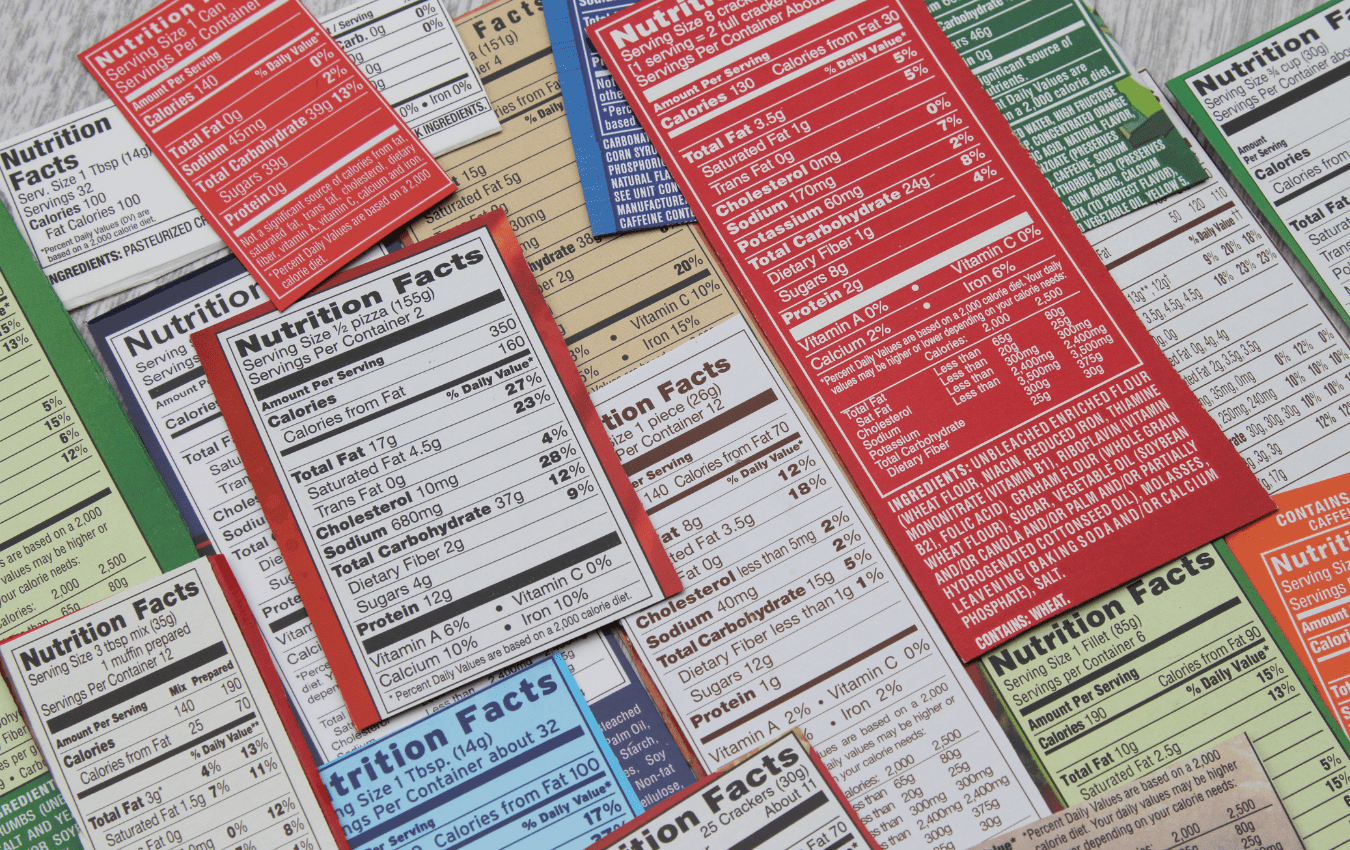

Food Labeling Regulations: A Guide for Packaging Buyers

As a packaging buyer, it is important to understand the regulations and requirements surrounding food labels to ensure that the packaging you purchase complies with all relevant laws and regulations. In this article, we will discuss what a packaging buyer should know about food labels before they buy their packaging.

Understand Food Labeling Regulations

Understanding food labeling regulations is crucial for packaging buyers to ensure that the packaging they purchase complies with all relevant laws and regulations. Food labeling regulations are designed to protect consumers by providing them with accurate and complete information about the products they purchase. The following are some key aspects of food labeling regulations that packaging buyers should be aware of:

Mandatory Labeling Information

The regulations require specific mandatory information to be included on food labels, such as the name of the product, list of ingredients, nutrition information, and allergen warnings. The label should also include the name and address of the manufacturer or distributor, along with the product’s country of origin.

Serving Size

Food labeling regulations require that the serving size be clearly indicated on the packaging. The serving size is important because it affects the number of calories and nutrients per serving. This information is crucial for consumers who want to monitor their intake of calories, sugar, fat, and other nutrients.

Nutrition Information

Food labeling regulations require that the nutrition information be provided on the label. This information includes the total amount of fat, protein, carbohydrates, vitamins, and minerals present in the product. The nutrition information should be presented per serving.

Allergen Warnings

Food labeling regulations require that allergen warnings be included on the label. If the product contains any of the eight major food allergens, including milk, eggs, peanuts, tree nuts, soy, wheat, fish, or shellfish, these must be clearly identified on the label.

Claims and Descriptors

Food labeling regulations also regulate the use of claims and descriptors on packaging. Claims such as “low-fat” or “high-fiber” must meet specific criteria, and any descriptors such as “natural” or “organic” must comply with strict labeling guidelines.

Consider Label Space

When designing or selecting packaging, it is essential to consider the amount of space available for labeling. Food labels can be quite detailed, and it is crucial to ensure that there is enough space on the packaging to include all necessary information. Here are some key considerations for packaging buyers when it comes to label space:

Regulatory Requirements

Buyers need to ensure that their packaging complies with regulatory requirements for labeling. These regulations specify the minimum required font size, layout, and location of certain label elements. Packaging buyers should work with their suppliers to ensure that the design of their packaging allows for all regulatory requirements to be met without compromising other essential elements of the packaging design.

Branding and Design

Buyers need to consider the branding and design of their packaging when planning for label space. Branding is essential for creating a strong brand identity and increasing consumer recognition of the product. It is essential to ensure that branding elements such as logos and graphics are given enough space on the packaging and are not obscured by label information.

Product Information

Food labels provide consumers with essential information about the product, such as ingredients, nutritional information, and allergen warnings. Packaging buyers need to ensure that there is enough space on the packaging to include all this information in a clear and legible format. It is essential to prioritize the information that needs to be displayed on the packaging and ensure that there is enough space for all required information.

Design Flexibility

Packaging buyers should also consider the flexibility of their packaging design when it comes to label space. The product may require additional labeling in the future due to changes in regulatory requirements or other factors. It is essential to ensure that the packaging design allows for flexibility and can accommodate any additional labeling requirements.

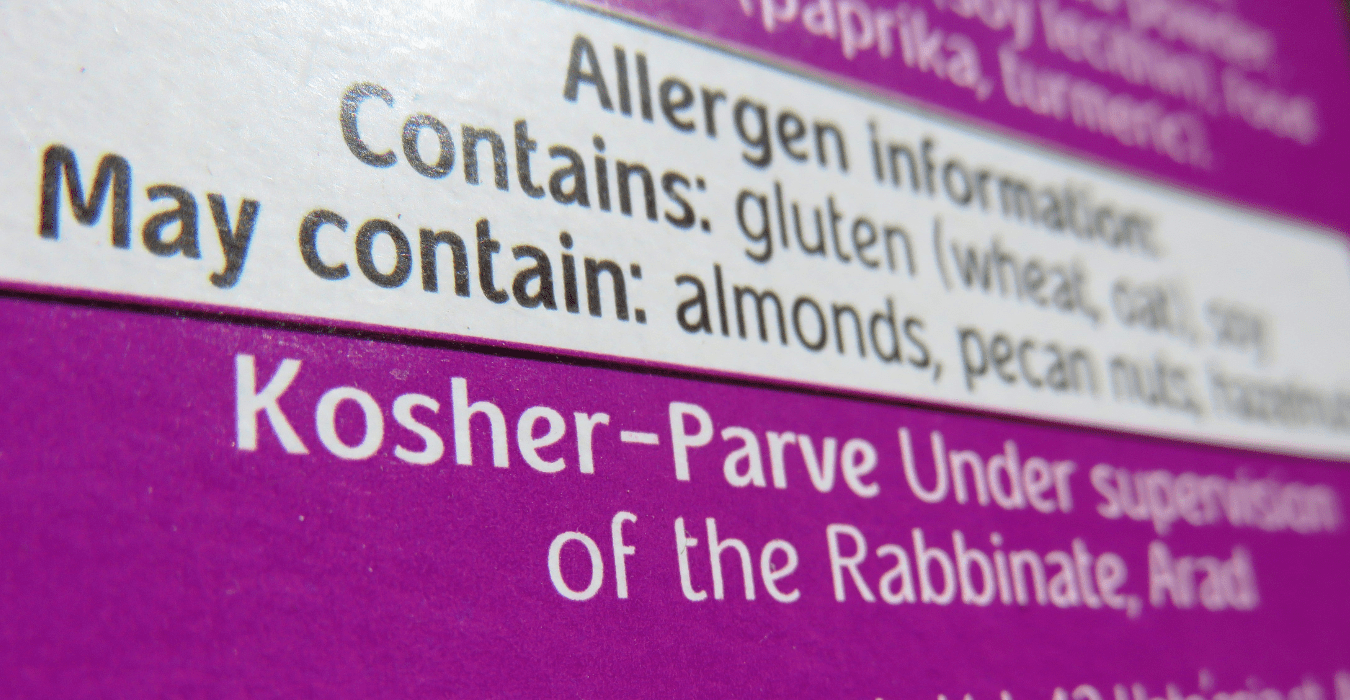

Ensure Compliance with Allergen Regulations

One of the most critical aspects of food labeling regulations is compliance with allergen regulations. As a packaging buyer, it is crucial to ensure that any packaging used for food products complies with regulations regarding allergen warnings. Here are some key considerations for packaging buyers when it comes to allergen regulations:

Know the Regulations

Food labeling regulations require that any product that contains one of the eight major food allergens, including milk, eggs, peanuts, tree nuts, soy, wheat, fish, or shellfish, must clearly identify the allergen on the label. Packaging buyers must know and understand these regulations and ensure that any packaging used for food products complies with them.

Use of Fonts and Colors

Regulations specify that allergen warnings must be easily visible and identifiable. Packaging buyers should work with their suppliers to ensure that the allergen warning is clear and easy to read. This may involve using specific fonts or colors for allergen warnings to make them stand out from other information on the label.

Prevent Cross-Contamination

In addition to labeling requirements, packaging buyers need to consider the risk of cross-contamination when selecting packaging for allergen-containing products. It is essential to ensure that any packaging used for these products does not pose a risk of cross-contamination with allergens.

For example, if a packaging facility produces a variety of products, including those that contain allergens, the packaging buyer should ensure that all products are packaged in separate areas to prevent cross-contamination. Packaging buyers should also consider the materials used in packaging and ensure that they do not contain any allergens that could migrate into the food.

Ensure Accurate Labeling

Allergen labeling must be accurate, and any changes to the product formulation or ingredients must be reflected in the labeling. Packaging buyers should work closely with their suppliers to ensure that any changes to the product are reflected in the packaging labeling.

Keep Up-to-Date with Changes in Regulations

As a packaging buyer, it is crucial to keep up-to-date with any changes in food labeling regulations that may impact the products you are packaging. Food labeling regulations are subject to change over time, and it is important to stay informed to ensure that your packaging remains compliant with all relevant laws and regulations. Here are some key considerations for packaging buyers when it comes to keeping up-to-date with changes in regulation:

Stay Informed

Packaging buyers should regularly review regulatory updates and industry news to stay informed about any changes in food labeling regulations. This can involve monitoring regulatory agency websites or subscribing to industry publications or newsletters.

Work with Suppliers

Packaging buyers should work closely with their packaging suppliers to ensure that they are aware of any changes in regulations that may impact their products. Packaging suppliers can provide valuable insights and guidance on how to adapt packaging designs to meet changing regulatory requirements.

Attend Industry Events

Attending industry events such as trade shows, conferences, and seminars can provide valuable opportunities to learn about new developments in food labeling regulations. These events offer the chance to network with other professionals in the industry and gain insights from expert speakers.

Evaluate Product Labeling Regularly

Packaging buyers should regularly evaluate the product labeling to ensure that it remains compliant with all relevant regulations. This can involve reviewing labels for accuracy, updating labels to reflect changes in product formulation or ingredients, and ensuring that any new regulatory requirements are met.

If you are interested in food labels or packaging, then contact Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Food Labeling Regulations: A Guide for Packaging Buyers

High-speed automated packaging lines can run hundreds of cartons per minute, but only if the carton’s design and material are optimized for smooth feeding, folding,

Holiday e-commerce volumes can overwhelm manual packing operations. Automation offers a scalable way to meet peak demand while maintaining accuracy, speed, and consistency. For packaging

Point of Purchase (POP) displays are a crucial element in the world of retail marketing. They play a significant role in catching the eye of