Home » Exploring Reverse Tuck End (RTE) Cartons: Functions and Features

Exploring Reverse Tuck End (RTE) Cartons: Functions and Features

Reverse Tuck End (RTE) cartons are a popular packaging solution known for their unique design and versatility. In this blog, we will delve into the functions and features of RTE cartons, focusing on their distinctive opposite tuck closure mechanism, which sets them apart from other carton styles.

Opposite Tuck Closure Mechanism

At the heart of the RTE carton’s design is its distinctive opposite tuck closure mechanism. This mechanism is characterized by having two tuck flaps—one at the top and one at the bottom of the carton—each tucking into the opposite panel, creating a secure and user-friendly closure. Let’s explore the functions and features associated with this design:

Secure Closure:

The primary function of the opposite tuck closure mechanism is to provide a secure seal for the contents of the carton. When the top flap is tucked into the rear panel and the bottom flap into the front panel, the carton is effectively closed, protecting the contents from external factors such as dust, moisture, and tampering. This ensures that the product reaches the end consumer in pristine condition.

Easy Accessibility:

One of the standout features of RTE cartons is their user-friendly design. Unlike some other carton styles that require complete opening, RTE cartons allow for convenient access to the product without the need to fully unseal the package. Consumers can easily open the carton by partially releasing one of the tuck flaps, retrieve the product, and then reseal it, maintaining the product’s freshness and usability.

Space for Information and Branding:

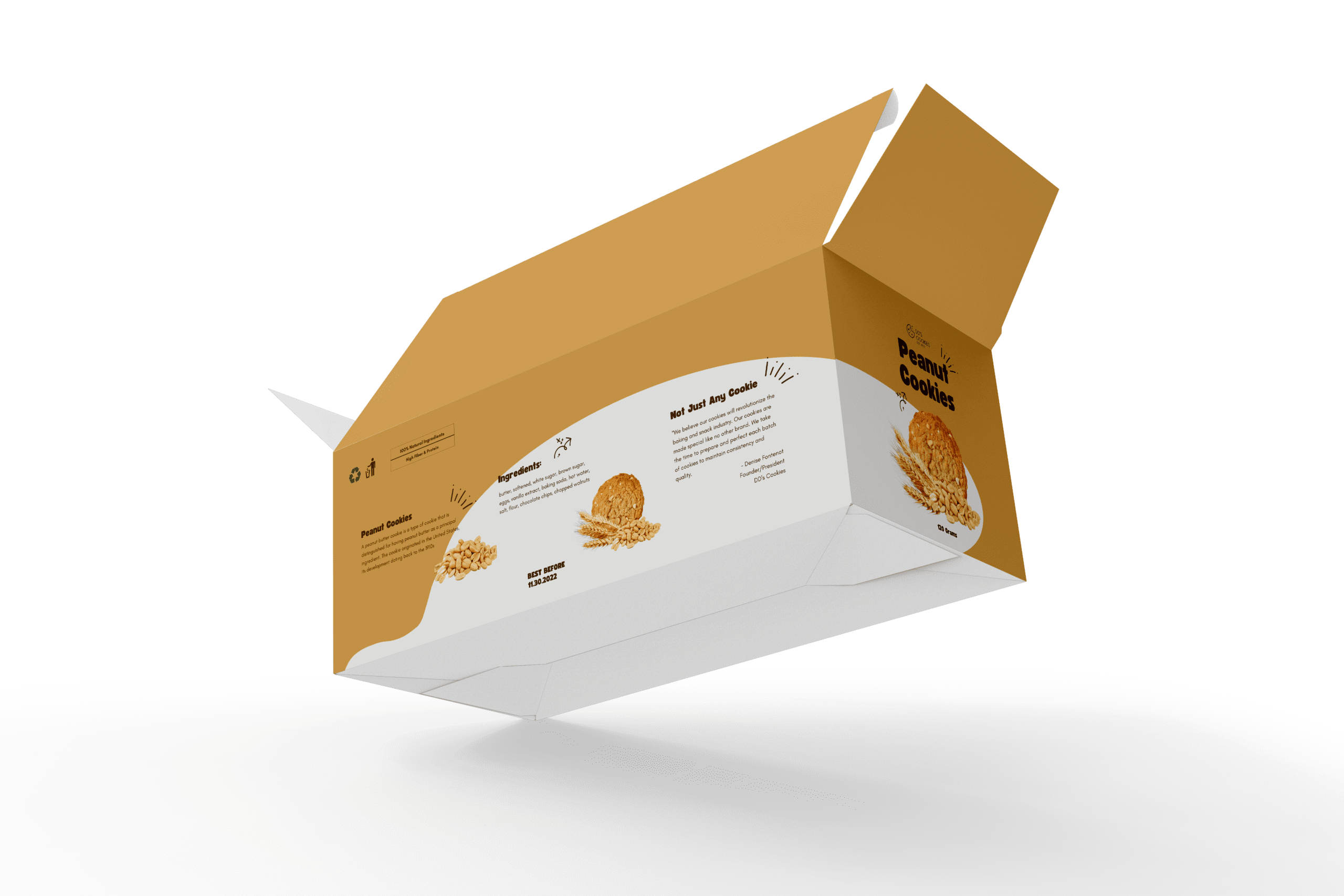

RTE cartons provide ample space for product information, branding, and graphics on both the front and rear panels. This design feature allows manufacturers and marketers to convey important details about the product, such as usage instructions, ingredients, and promotional messaging. Additionally, the extended surface area offers an excellent canvas for eye-catching visuals and branding elements, enhancing the product’s shelf appeal.

Efficient Storage and Stacking:

RTE cartons are designed with efficiency in mind. Their rectangular shape and opposite tuck closure facilitate easy stacking and storage. Whether on store shelves or in warehouses, RTE cartons maximize space utilization, making them a practical choice for businesses with storage constraints.

Versatile Applications:

RTE cartons are highly versatile and suitable for a wide range of products and industries. Their ease of use, secure closure, and ample branding space make them a preferred choice for packaging electronics, hardware, pharmaceuticals, consumer goods, office supplies, and more.

If you are interested in reverse tuck end folding cartons, then partner with Brown Packaging today to get started.

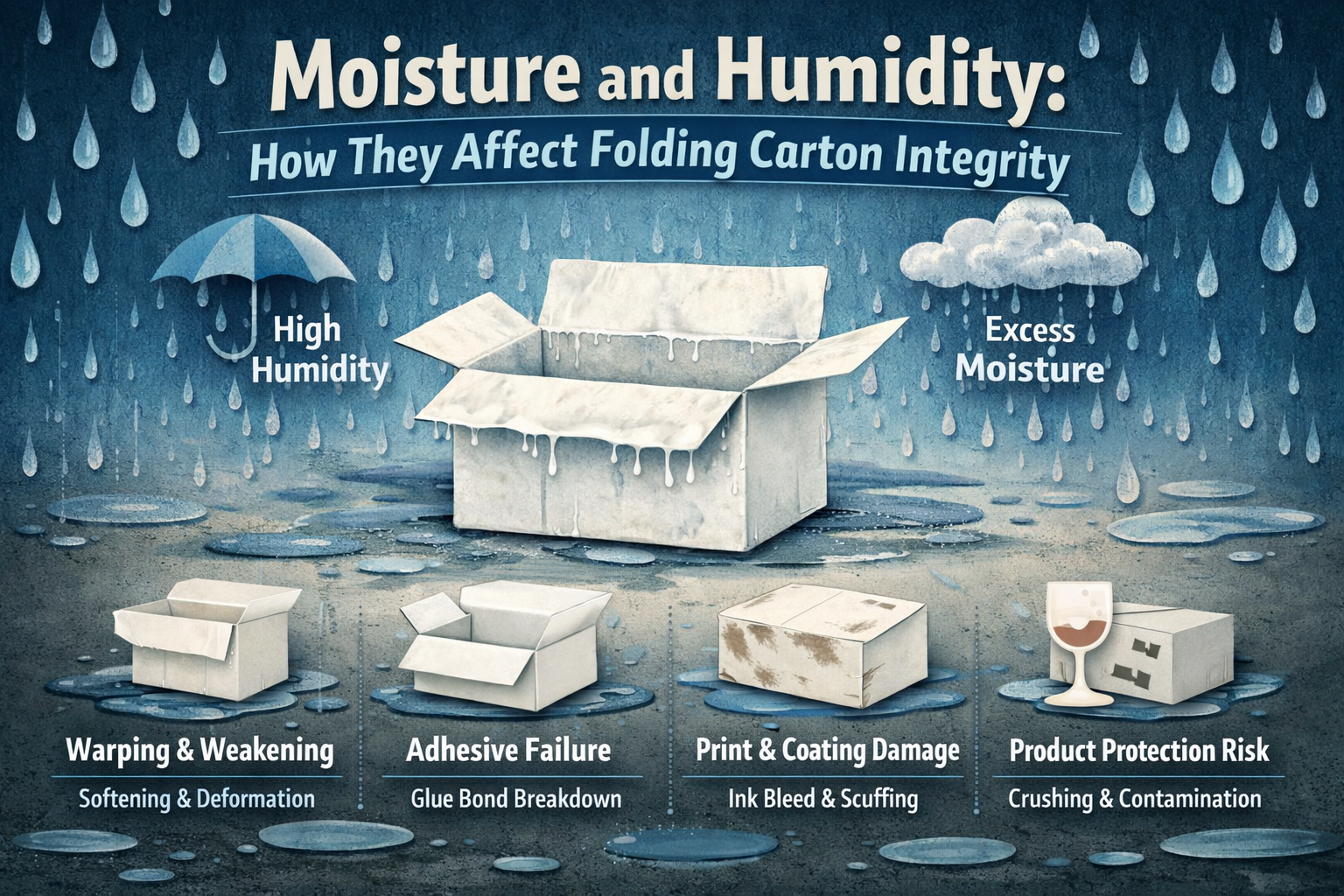

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Exploring Reverse Tuck End (RTE) Cartons: Functions and Features

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Straight Tuck End (STE) folding cartons are a popular and widely used type of packaging for consumer goods such as food, beverage, cosmetics, and household

What is Chipboard? Chipboard is made from small wood particles mixed with resin, binders and other additives, which is then pressed together under high temperature