Home » Exploring Alternative Packaging Options for Mailing Tubes

Exploring Alternative Packaging Options for Mailing Tubes

Mailing tubes have long been a popular choice for shipping and storing various items, from posters and blueprints to documents and delicate artworks. While they serve their purpose effectively, there are alternative packaging solutions that can offer unique advantages and benefits. In this comprehensive guide, we will explore alternative packaging options to mailing tubes, considering various materials, designs, and their suitability for different types of contents.

The Limitations of Mailing Tubes

Before delving into alternative packaging options, it’s essential to understand the limitations of mailing tubes:

Limited Shape Compatibility: Mailing tubes are primarily designed for long, cylindrical items. They may not be suitable for irregularly shaped or flat objects.

Lack of Padding: Mailing tubes typically provide minimal protection against impact and bending. Fragile or sensitive items may require additional padding.

Storage Challenges: Mailing tubes can be difficult to store efficiently, especially when dealing with a large quantity of varying tube sizes.

Now, let’s explore alternative packaging options:

Corrugated Boxes

Corrugated boxes come in various sizes and shapes, making them versatile for different types of items. They offer more robust protection than mailing tubes and can be customized with dividers, foam inserts, or partitions to secure fragile objects. Corrugated boxes are also easier to stack and store.

Bubble Mailers

Bubble mailers, or padded envelopes, are lightweight and provide cushioning for small to medium-sized items. They are an excellent choice for documents, books, clothing, and small electronics. Bubble mailers come in different sizes and offer a cost-effective alternative to mailing tubes.

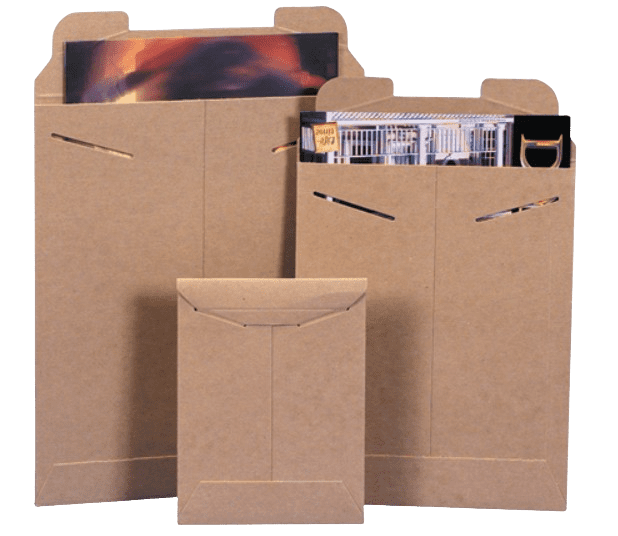

Flat Mailers

Flat mailers are perfect for shipping flat or thin items such as photographs, artwork, or documents. They are designed to prevent bending or damage during transit. Flat mailers often have rigid or reinforced designs for added protection.

Expandable Mailers

Expandable mailers are ideal for items that may vary in thickness. They feature a gusseted design that allows the mailer to expand to accommodate thicker contents. This versatility makes them suitable for various products, including books and catalogs.

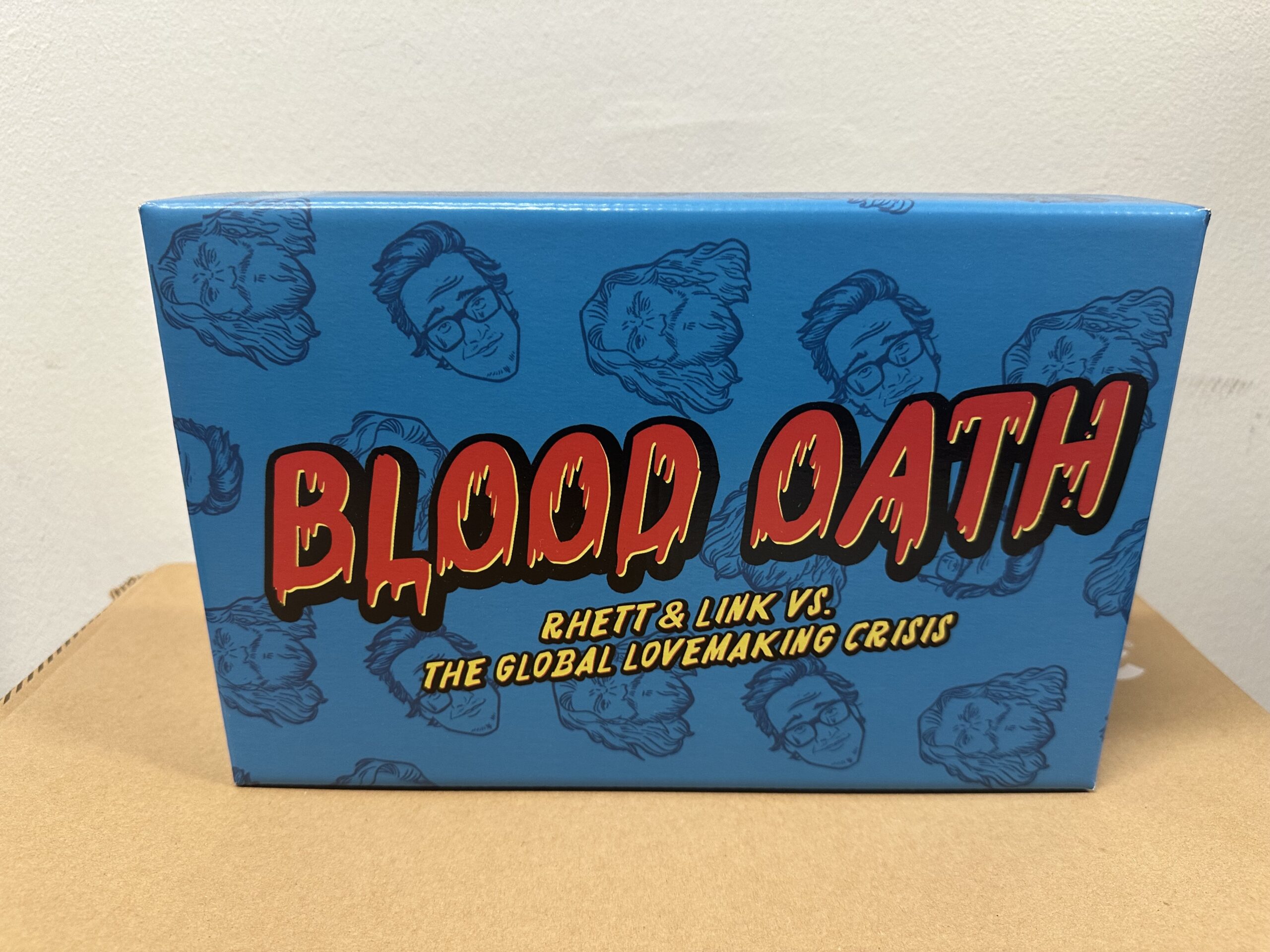

Rigid Mailers

Rigid mailers, also known as chipboard mailers or stay flat mailers, provide sturdy protection for delicate items like photographs and prints. They are constructed from rigid cardboard or paperboard and come in various sizes.

Telescopic Boxes

Telescopic boxes consist of two parts that slide into each other, providing adjustable length. They are a great alternative for items that require a secure and expandable packaging solution, such as posters or rolled documents.

Poly Mailers

Poly mailers are lightweight and water-resistant, making them suitable for shipping clothing, accessories, and non-fragile items. They come in various sizes and can be customized with branding or labeling.

Custom Packaging Solutions

Depending on your specific needs, you can explore custom packaging solutions tailored to your product requirements. Custom packaging allows you to design packaging that perfectly fits your items, ensuring maximum protection and brand presentation.

Choosing the Right Alternative

Selecting the right alternative packaging to mailing tubes depends on the nature of your products, shipping requirements, and budget considerations. Carefully assess the size, shape, and fragility of your items, as well as your branding and sustainability goals. By exploring these alternative packaging options, you can find a solution that not only protects your contents during transit but also aligns with your overall packaging strategy.

If you are interested in alternative packaging to mailing tubes, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are learning that premium doesn’t always

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of actual or dimensional weight, which

Home » Exploring Alternative Packaging Options for Mailing Tubes