Home » Enhancing Retail with POP Displays and Trap Blister Packs

Enhancing Retail with POP Displays and Trap Blister Packs

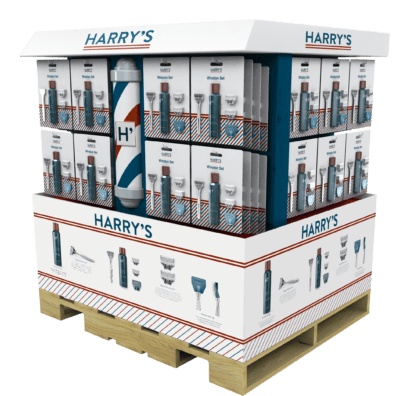

In the dynamic world of retail, the collaboration between POP Displays and Trap Blister Packs holds immense potential. These two elements – POP Displays and Trap Blister Packs – play crucial roles in enhancing product visibility and transforming the shopping experience. In this exploration, we’ll explore into how these components work together and the significant impact they have on the retail landscape.

The Power of POP Displays

At its core, a POP Display is a strategic tool that transforms products into captivating visual statements. From countertop arrangements to floor displays, POP Displays are expertly designed to capture attention and drive impulse purchases.

Unveiling the Magic of Trap Blister Packs

Trap blisters are a packaging solution that effortlessly combines transparency with protection. This packaging innovation securely encases products within a clear plastic blister, offering both a view of the product and a secure enclosure.

A Dynamic Partnership

The interaction between POP Displays and Trap Blister Packs creates a powerful synergy. While POP Displays attract attention, Trap Blister Packs provide a clear view of the product, enticing customers to explore further.

Enhancing the Customer Journey

The synergy between these elements goes beyond aesthetics, enriching the customer journey. The eye-catching display draws shoppers in, and the transparent packaging allows for an up-close interaction with the product, enhancing the overall shopping experience.

The Role of Trap Blister Packs in the World of POP Displays

- Balancing Visibility and Security: Trap Blister Packs strike a balance between visibility and security, offering customers a tantalizing look at the product while keeping it protected.

- Visual Consistency: The uniform, crystal-clear appearance of Trap Blister Packs complements the aesthetics of POP Displays, ensuring a seamless and immersive presentation.

- Protection: Trap Blister Packs shield products from dust, moisture, and physical damage, preserving their pristine condition.

Effective Strategies

- Unified Presentation: Coordinate the design of Trap Blister Packs with the POP Display to create a captivating, cohesive shopping atmosphere.

- Informative Design: Utilize the available space on Trap Blister Packs to convey vital information, enticing customers with features and benefits.

- Ease of Interaction: Prioritize user-friendly packaging that enables customers to engage effortlessly with the product.

Extending to the Digital Realm

The impact of Trap Blister Packs extend beyond physical stores. In the digital realm, these elements seamlessly adapt to e-commerce, providing clear visuals and product details that mirror the in-person experience.

If you are interested in pop displays or trap blister packs, then partner with Brown Packaging today.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Enhancing Retail with POP Displays and Trap Blister Packs

In the competitive retail landscape, capturing consumers’ attention is more crucial than ever. One strategic approach to achieve this is through effective point of purchase

Point-of-purchase (POP) displays play a dual role in retail environments: they must capture attention with graphics while supporting products with reliable structure. If one side

Point of purchase displays, also known as POP displays, are an essential marketing tool for businesses to showcase their products and attract customers. However, creating