Home » Different Types of Sealing and Closures for Corrugated Boxes

Different Types of Sealing and Closures for Corrugated Boxes

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of sealing and closure not only ensures the safety and security of the contents but also can enhance ease of use, storage, and even branding. This blog post explores the different types of sealing and closure methods available for corrugated boxes, helping businesses choose the best option for their specific needs.

Understanding the Importance of Proper Sealing and Closure

Before delving into the types, it’s crucial to understand why sealing and closure matter. The right closure method can protect the contents from damage, theft, or contamination, while also providing an additional layer of branding through custom tapes or seals.

Tape Closure

One of the most common methods of sealing corrugated boxes is using tape. This method is versatile and cost-effective, suitable for a wide range of applications.

- Pressure-Sensitive Tape: Easy to apply, available in various widths and strengths, and ideal for lightweight to medium-weight boxes.

- Water-Activated Tape (WAT): Forms a strong bond with the corrugated box, offering superior security, and is excellent for heavier packages.

- Reinforced Water-Activated Tape: Best for heavy-duty applications, providing extra strength and security.

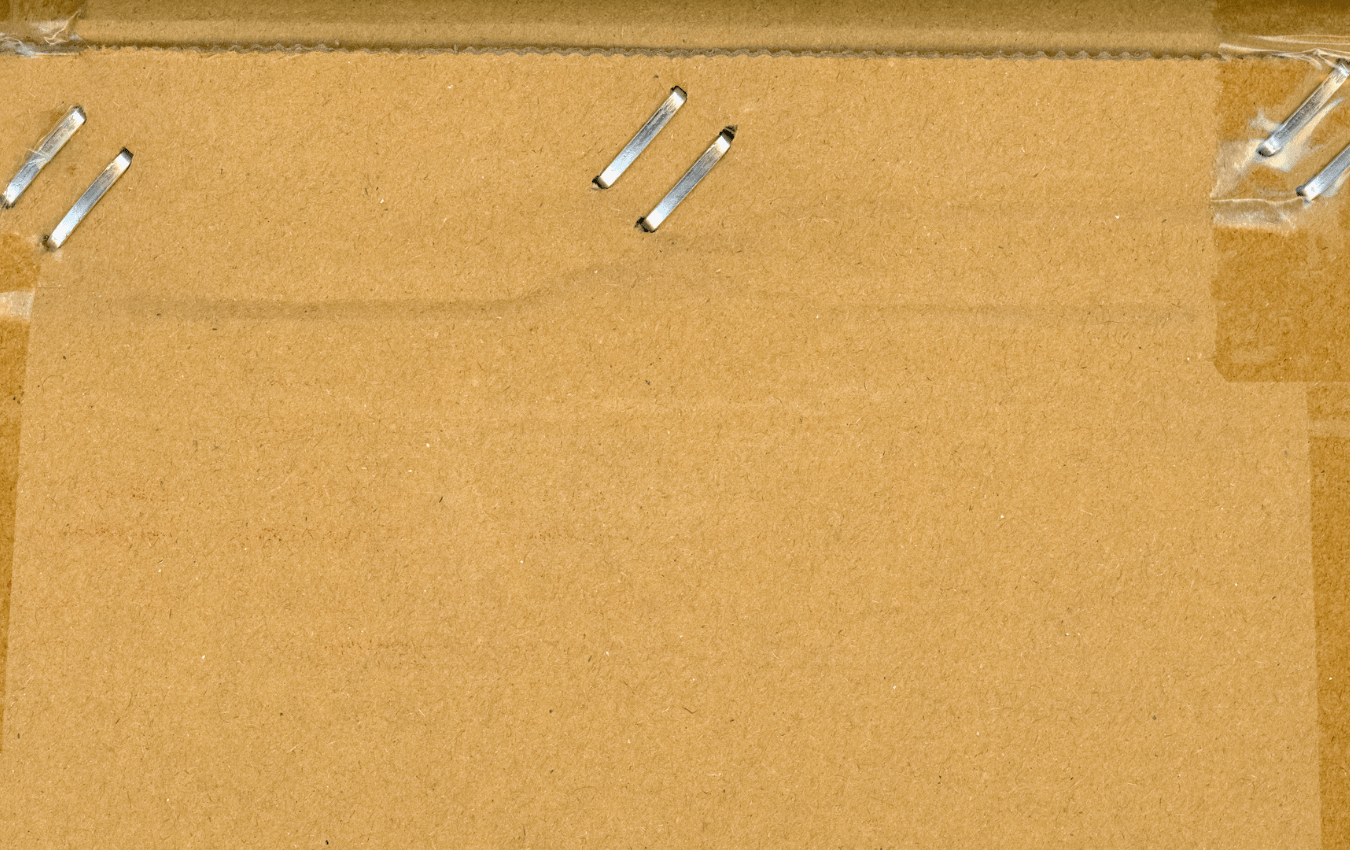

Staple Closure

Stapling is a traditional method of closing corrugated boxes, often used for heavy or industrial items.

- Manual Stapling: Suitable for small-scale operations or where additional security is needed.

- Pneumatic Stapling: Used in larger operations for efficiency and consistency in sealing.

Glue Closure

Adhesive or glue is another popular method, especially in automated packaging lines.

- Hot Melt Adhesive: Quick to apply and set, providing a strong and durable seal.

- Cold Glue Adhesive: Requires more time to set but offers a strong bond and is suitable for boxes that require refrigeration.

Self-Locking Tabs and Slots

For consumer-facing products, self-locking tabs and slots offer an appealing and tool-free option.

- Tab Lock: Simple to use, providing a secure closure without additional materials.

- Slot Lock: Offers added security as tabs lock into slots, making the box more tamper-resistant.

Velcro or Hook-and-Loop Closures

For reusable box designs, Velcro or hook-and-loop closures are ideal.

- Easy Open and Close: Allows for multiple uses, ideal for sample kits or storage boxes.

- Customizable: Can be designed in various shapes and sizes to suit specific packaging needs.

Strapping or Banding

Strapping or banding is used for heavy-duty applications or for bundling multiple boxes together.

- Metal Strapping: Offers the highest strength, ideal for heavy industrial goods.

- Polyester or Polypropylene Strapping: More flexible than metal, suitable for a wide range of applications.

Sealing with Labels or Stickers

Custom labels or stickers can double as a sealing method, particularly for light packages or as an additional security seal.

- Branding Opportunity: Custom labels provide a platform for branding and product information.

- Tamper-Evident Seals: Enhance security by indicating if the box has been opened.

Conclusion

The choice of sealing and closure method for corrugated boxes depends on several factors, including the weight and nature of the contents, the shipping and handling process, the need for security, and the desired customer experience. By selecting the appropriate sealing and closure method, businesses can ensure their products are well-protected and arrive at their destination in the best possible condition. Moreover, creative and practical sealing solutions can enhance brand recognition and provide an additional touchpoint for customer engagement.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » Different Types of Sealing and Closures for Corrugated Boxes